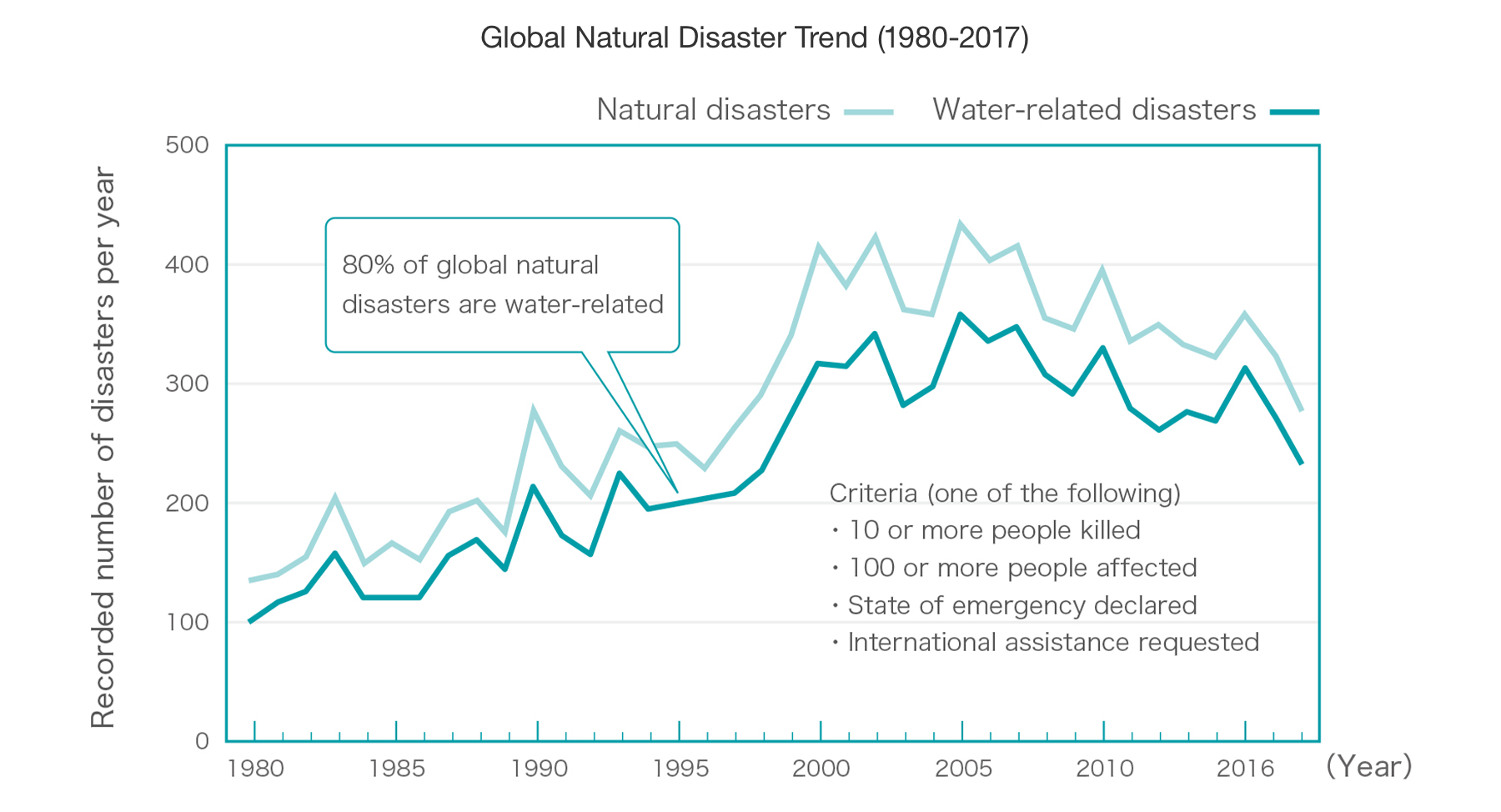

In recent years, increasingly large typhoons and effects of climate change have led to a rising number of overflowing rivers, floods, and landslides caused by heavy rains, inflicting major damage on many parts of Japan. Some studies indicate that about 80% of the world's natural disasters are water-related, and their risks will continue to increase due to global warming and other changes in the climate. With the increasing scale and urgency of water-related disasters, rapid recovery and reconstruction will be needed in affected areas to protect people's lives and livelihoods.

Drainage pump vehicles are dispatched to disaster sites to carry out recovery efforts. Kubota, one of the pump manufacturers contracted by the Japanese government, has been involved in the development, manufacturing, and sales of drainage pump vehicles since 1991. Today, most drainage pump vehicles deployed by Japan's Ministry of Land, Infrastructure, Transport and Tourism are manufactured by Kubota. In this article, we will examine the thoughts and feelings of the people involved in drainage pump vehicles, which play a vital role in disaster recovery efforts.

Water-Related Disasters Rage Worldwide

Each year throughout the world, all kinds of natural disasters harm people’s daily lives. According to international disasters database EM-DAT, the number of natural disasters is on the rise globally, with water-related disasters such as floods, storms, and tsunamis accounting for 80% of the total.

The torrential rains that hit western Japan in July 2018 and Typhoon Hagibis, which struck large portions of the Kanto, Koshin, and Tohoku regions in October 2019, are still fresh in the minds of the Japanese.

The Japan Meteorological Agency reported that the torrential rains in western Japan were affected by increased water vapor caused by global warming. Cases such as these indicate a close relationship between global warming and water-related disasters. If warming continues at the current rate, water-related disasters could become even more frequent and more severe.

Kubota Drainage Pump Vehicles Combine Mobility with Drainage Capacity

Torrential rains induced by climate change and increasingly large typhoons are causing more and more instances of water-related disasters in sizes that exceed expectations. Existing drainage pump stations are unable to handle these, leading to flood damage in many areas. What is more, if this damage extends to pump locations, the inundation will remain unresolved for long periods of time. Drainage pump vehicles are trucks that go to such areas and provide drainage services. These trucks rush to the frontlines of disaster sites such as flooded residential areas and inundated roads to drain the accumulated water into rivers and waterways and return people's lives to normal as quickly as possible.

Unfortunately, it is impossible to predict the circumstances of the affected areas where the drainage pump vehicles will be working. Takashi Segawa of Kubota’s Environmental Engineering Sales Department says, "Kubota has been developing and innovating drainage pump vehicles with a focus on mobility and lighter weight for pumps in order to meet needs in any kinds of situations." Each vehicle is equipped with multiple drainage pumps that can each drain 7,500 liters of water per minute and can be set up by hand, meaning that each vehicle can drain around 60,000 liters of water per minute. This is enough capacity to empty a 25-meter pool in about five minutes. "It's all because we want to return the lives of everyone in the affected areas to normal as quickly and as dependably as possible," says Mr. Segawa.

Improving Drainage Pump Vehicles and Expanding the Range of Needs

Development of drainage pump vehicles started with a request from the Japanese government. They were initially intended for use in rivers. Improvements were later added to the vehicles to make them more maneuverable, and they were increasingly used in places other than rivers, such as underpasses for national highways. Hiroshi Takeda, also of the Environmental Engineering Sales Department, says that new needs arose as a result of these improvements.

“We had been using the pumps in the deep water of rivers, but as they became used in more and more cases, new requests came to use them in shallower depths of water,” says Takeda. “That’s why we developed a pump that could be used in low water levels and attached it to the vehicles. We are working to address customer needs and further reduce the damage from disasters by improving our products across our pump business, including drainage pump vehicles.”

In addition to the national government, more and more local governments throughout Japan are using the vehicles. The drainage pump vehicle originally required a driver's license for large vehicles, but local governments could not always secure drivers with such licenses. In response, Kubota developed them small enough to be driven with a license for medium-sized vehicles.

Mr. Segawa says that Kubota is currently receiving numerous inquiries about drainage pump vehicles from local governments. “Each municipality has different needs,” he says. “We at Kubota want to meet those requests as much as we can. Regardless of where a disaster occurs, we hope that the vehicles can provide greater assistance for faster recovery efforts.”

The introduction of pumps for low water levels and lighter weight for use with a license for medium-sized vehicles are just some of the improvements that have been made in drainage pump vehicles. But Ryutaro Kotaka of the Environmental Engineering Design and Procurement Department, who is in charge of the vehicles’ design, says, “It’s very important to make the vehicles more durable so they can keep draining in unfavorable environments. For example, temperatures can rise to nearly 40°C (104°F) on the day after a typhoon. Such conditions can cause overheating in the control panels and generators that operate the pumps. That’s why we equipped Kubota’s drainage pump vehicles with advanced cooling capabilities. We cannot anticipate the kind of environments they will be used in, so all kinds of problems are possible. But we have considered each problem and made numerous improvements in quality that have resulted in the vehicles we offer today.”

Engineers Make Strenuous Efforts in Disaster Areas

As the scale of water-related disasters increases, the roles fulfilled by drainage pump vehicles has also evolved. In a disaster affecting many lives like the Great East Japan Earthquake, which triggered a massive tsunami, drainage pump vehicles play the vital roles of saving lives and searching for those who are missing through drainage efforts, roles that were not originally imagined.

Drainage pump vehicles are usually used by workers with the national government or the municipalities that ordered them. However, in a large-scale disaster or other unexpected case, requests come to Kubota, which manufactured the vehicles, and Kubota Kikou Corporation, which has a number of professionals in pump maintenance. These companies dispatch engineers to handle mechanical issues and provide other services needed at disaster sites. Takeshi Tomitsuka, who works in the Environmental Engineering Construction Department, was one of the employees sent to assist with recovery efforts in 2011 during the Great East Japan Earthquake and the Thailand floods.

The Great East Japan Earthquake was a magnitude 9.0 earthquake that triggered a massive tsunami, causing tremendous damage along the Pacific coast of Japan’s Tohoku region. Massive amounts of flooding occurred over large areas, damaging existing drainage pump stations. In response, the Ministry of Land, Infrastructure, Transport and Tourism brought in drainage pump vehicles from all over Japan and operated them around the clock to drain the water. However, in such an unprecedented disaster, the drainage pump vehicles that worked constantly at the forefront of recovery efforts faced numerous difficulties.

“In the Great East Japan Earthquake, drainage pump vehicles had to operate in areas where debris and other objects were flowing,” says Mr. Tomitsuka. “The pumps were sucking in foreign objects, leading to problems. Sometimes rubber objects would get caught in the impeller, the main part of the pump, causing deformation and damage. Regardless, we had to drain the flood water and find victims as quickly as possible, so we couldn’t stop our work. We wanted to do all we could without cutting corners, so we made whatever repairs we could on the spot, and in the meantime asked the factory to send new equipment.”

Emergency drainage work with drainage pump vehicles was carried out for more than five months. In total, more than 4,000 vehicles were dispatched to 16 cities and towns in three prefectures. They were used for emergency drainage at Sendai Airport and areas such as the Kamaya district of Ishinomaki City and the Tomei district of Higashi-matsushima City. These vehicles assisted in search and rescue efforts for people who went missing in the tsunami.

The Thailand floods occurred a few months after the Great East Japan Earthquake. The inundations hit not only agricultural areas but also industrial zones and cities, and the waters did not recede for a long time. Japan's Ministry of Land, Infrastructure, Transport and Tourism sent ten drainage pump vehicles and a team of more than 20 experts from Japan to the region, and Mr. Tomitsuka was also dispatched there.

"For the Thailand floods, we had to deploy pumps in areas where trees and grasses had sunk and we didn't know how deep the water was," recalls Mr. Tomitsuka. "Also, riverbanks and beds were not as developed there as they were in Japan, so we were not sure whether we could really send the pumps down and how much debris there would be. But despite the circumstances, Kubota's pumps kept working, even when they drew in tree branches and sand. I work for Kubota and even I was surprised by how good they really were." The drainage efforts continued for about a month, moving to multiple industrial zones and contributing to faster recovery.

Aiming for Improvements to Drainage Pump Vehicles

To ensure that the needs from drainage pump vehicles can be met, Kubota continues to make improvements. "Each year, we work to reduce the size and weight of our pump vehicles by a few centimeters or tens of kilograms without compromising on quality," says Mr. Kotaka. We can expect these changes to improve mobility and provide better support for recovery efforts in disaster areas. I have met directly with people who have been impacted by floods, and I hope that Kubota will be able to fulfill the wishes of those impacted by disasters and create products that will ensure safety for everyone." His words express his hopes for further improvements in drainage pump vehicles.

The best hope of all is for a quiet and secure life in which drainage pump vehicles are not necessary. Unfortunately, trends indicate that water-related disasters are likely to become more frequent and more severe in the future. And once a major disaster occurs, its severity could threaten our lives and livelihoods. To prepare for such an emergency, Kubota is making innovations in its drainage pump vehicles. Mr. Takeda says, "We are improving operability and integrating IoT in our efforts to provide pumps that can better mitigate damage," and such improvements could make these vehicles an even more powerful and effective tool in disaster response. Our interview with him gave us a sense of the drive that he and others share to delve into the unpredictable environment of disaster areas and struggle to make every possible improvement in order to protect people's lives through the use of drainage pump vehicles.