Understanding the Materials, Polishing Its Skills, and Responding to User Needs—Kubota’s Passion Supports Industries Worldwide

Materials

Parts and components formed by processing raw materials with heat, pressure, etc. are called “sokeizai (materials).” These materials are essential to the products that surround us as well as indispensable to the manufacturing industry. Kubota studied raw materials, polished its skills, and provided what the customers genuinely sought for. Behind this was Kubota’s passion for contributing to the society. It can be said that the materials business is one of the businesses that embodies Kubota’s principles. With a thorough understanding of raw materials, Kubota’s forged materials continue to support industries around the world today.

Scroll Down

Improving the Urban Infrastructure

Construction Machinery

For the Future of Food and Humanity

Agricultural Machinery

1930-1950s

Expansion of Private Demand

In 1930s, the heavy and chemical industries, such as iron, automobile, aircraft, and machine industry, were booming. The casting industry, which supported the machine industry, became extremely busy with increased production of military supplies. However, once the war ended, the industry was forced to respond from military demand to private demand and was left to search for a path for survival.

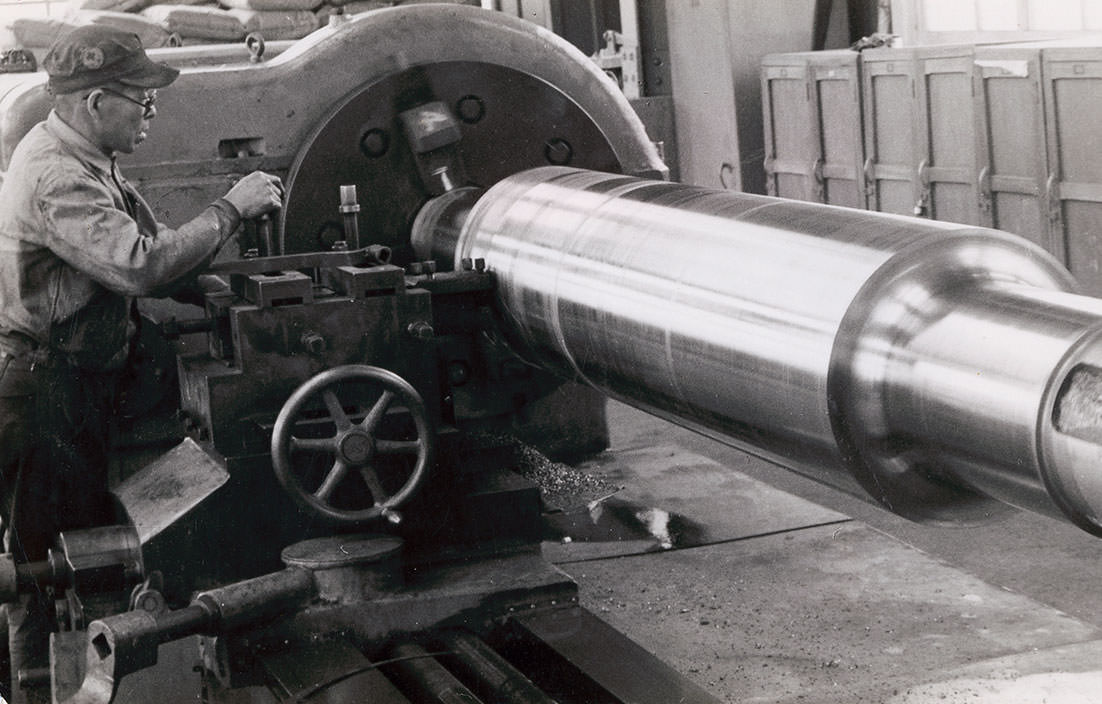

Steel Ingot Mold, Ductile Cast Iron Roll

Kubota’s Cast Steel Technology Found New Opportunities in Special Steel Casting

After much trial and error, Kubota expanded its market from cast iron to cast steel. In order to differentiate itself from other companies, it focused on special cast steel and developed the Japan’s first steel pipe through centrifugal casting.

1950-1960s

As Japan Entered the Period of Rapid Economic Growth, the Urban Infrastructure Developed

After much trial and error, Kubota expanded its market from cast iron to cast steel. In order to differentiate itself from other companies, it focused on special cast steel and developed the Japan’s first steel pipe through centrifugal casting.

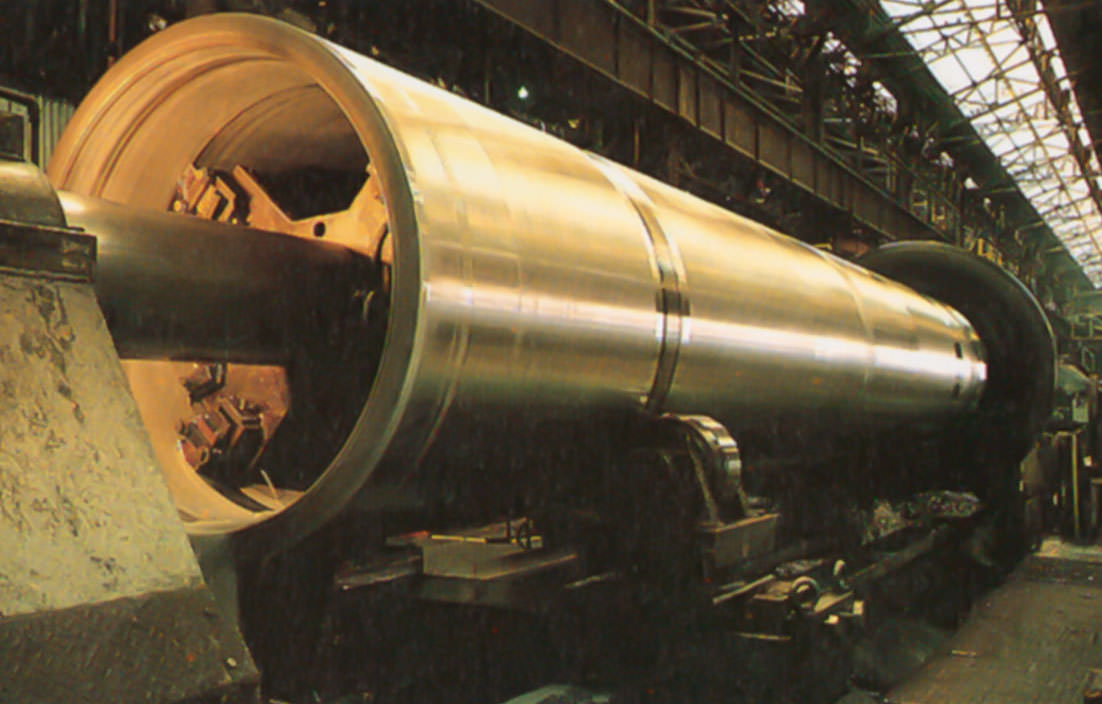

G Column for Building Structure, Centrifugal Cast Composite Roll, Spiral Iron Pipe

Further Developing Product Originality, Kubota Entered the New Field of Civil Engineering

Kubota, which owned the centrifugal casting technology for cast steel pipe, further promoted research pursuing product individuality. It entered new markets including casting materials for civil engineering construction.

1970s

Kubota’s Symbolic Cast Steel Product that Supported the Shipbuilding Boom

As the “Building a New Japan” boom started and the development of transportation network accelerated, public works projects also increased. Thus, the civil engineering industry began to thrive even more. Accordingly, the steel pipe pile industry also flourished. Construction works became larger in scale, and the demand for products also changed.

Spiral Steel Pipe Pile, Cargo Oil Pipe

Creation of Kubota’s Symbolic Cast Steel Product Through the Expansion of Its Steel Pipe Business

Kubota exerted a strong presence in the market with its highly unique special steel pipes. Along with the shipbuilding trend and “Building a New Japan” boom, the production of cargo oil pipes for oil tankers and steel pipe piles grew exponentially. These items joined the line of Kubota’s representative cast steel products.

1970-1980s

The Oil Crises Brought on Changes to the Industrial Structure and Innovation

In 1973, oil prices exponentially rose as a result of the oil crisis, and the world was at once plunged into recession. As one way to overcome this crisis, countries promoted energy and resource efficiency. However, this brought on a change to the industrial structure and encouraged the development of new technologies and products.

Cylinder Liner, Hearth Roll, Suction Roll, Reformer & Cracking Tube, Cast Iron Parts for Nuclear Power Generation

Restructuring the Business After the Oil Crisis

The casting and cast steel businesses suffered a major blow as a result of the oil crisis in Japan. Looking for new directions in order to survive, opportunities rose for regularly creating new technologies and products.

1980-2000s

The Bubble Economy and the Diversification of Customer Needs

Due to the rise and fall of the bubble economy triggered by the depreciation in Japanese yen, the country entered a period of long economic stagnation. While domestic demand faltered, the diversification of customer needs further accelerated. In order to respond to this diversification and differentiate its products, industries focused on developing new products and materials.

Reformer & Cracking Tube, Skid Button, Composite Ring Roll

The Birth of the Materials Business. Kubota Expanded its Domain with New Materials and New Technologies

Responding to diversifying customer needs with the concept of “forged materials,” Kubota newly established the Material Consolidated Division and devoted itself to developing new material qualities and technologies. As a result of this endeavor, it created numerous products that represent Kubota’s material business today.

2000s-

The Acceleration of Economic Globalization and Diversification of Needs

In recent years, economic globalization has progressed at an unprecedented pace, and emerging countries such as China, Russia, India, and Brazil have developed economically. Meanwhile, with a weak economy, Japanese businesses have stagnated altogether, and industries rapidly pursued rationalization, as customer needs further diversified.

Reformer & Cracking Tube, TXAX, Laqnican Joint

The Globalization of Kubota’s Business and the Increasing Segmentation of Customer Needs

Along with economic globalization, Kubota reinforced its business foundation for public sector demand and promoted overseas growth strategies. It responded to the needs both in and outside Japan with reliable technology.