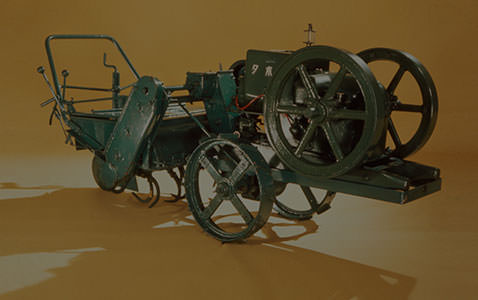

Where It All Started. Cast Iron Pipe Embodying the Founder’s Spirit

Pipe System

The water pipe is one of the products that represent Kubota’s corporate philosophy. What made possible the wholehearted devotion in making one iron pipe, becoming the first in the country to develop and mass-produce this product, was Founder Gonshiro Kubota’s tireless effort and strong conviction. His passion that led to this brilliant achievement—for the country and the people who lived there—can still be found in various aspects of Kubota’s technology and products today. In this way, the pipe system business, which started from manufacturing water pipes, is reminiscent of the founder’s spirit and encapsulates the history of the company itself. Kubota’s iron pipes play a significant role, supporting the public infrastructure.

Scroll Down

Japanese Technology Goes Global

Water Solution

The Iron Heart that Moves Industries

Engines

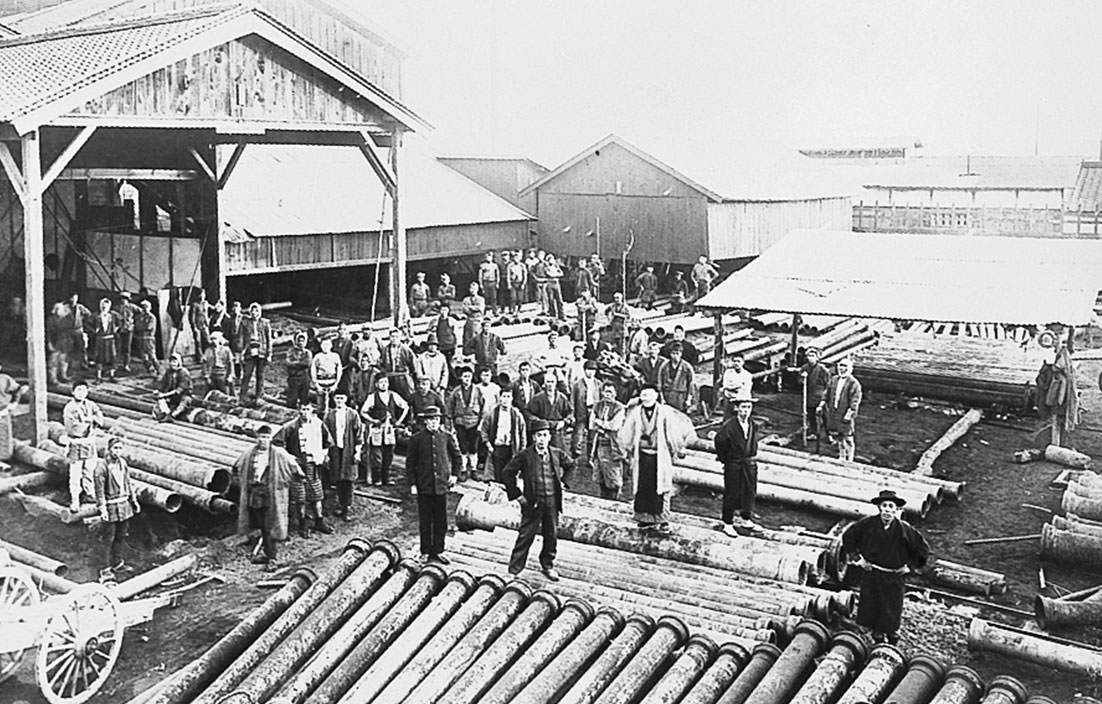

1890-1900s

Demand for Water Infrastructure Rose as Infectious Diseases Spread

Along with Japan’s Westernization movement during the Meiji Era, infectious diseases such as cholera were introduced to and spread throughout the country, causing many deaths. In response, the government proposed to the development of water infrastructure and promoted the establishment of modern water supply systems around the country. In Osaka City, attempts were made to manufacture iron water pipes domestically in order to encourage the growth of new industries.

Iron Pipe, Valve

Until the Production of Domestic Iron Pipes

The company founder, Gonshiro Kubota, challenged to domestically produce water pipes, which were dependent on imports. Gonshiro’s passion and dedication to cast water pipes gave birth to new technology.

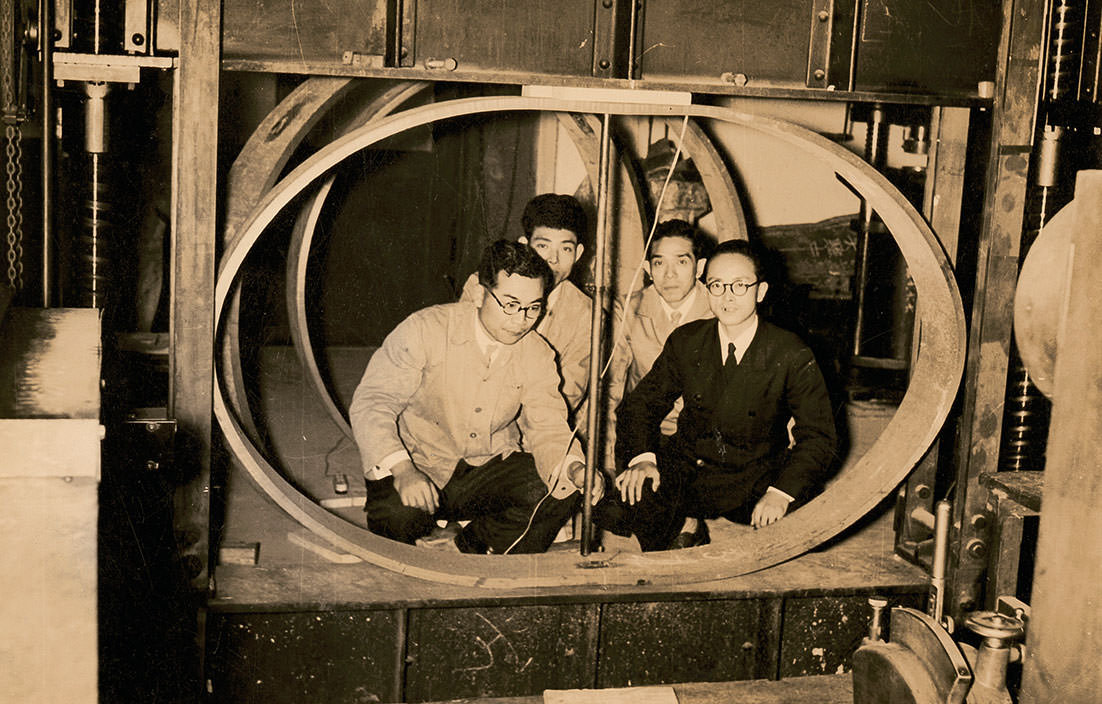

1940-1950s

Water Infrastructure is Restored, Overcoming Resource Shortages

The air raids during the final period of World War II destructed over 90 cities in Japan. After the war, the GHQ put great effort into hygiene measures, and water infrastructure restoration was carried out at a rapid pace. Meanwhile, Japan had scarce resources, and manufacturers struggled to produce iron pipes, though restoration progressed little by little.

Iron Pipe, Valve, Polyvinyl Chloride Pipe, Pump

Started Developing Waterworks Supplies—The Origin of Kubota’s Water-Related Business

As water infrastructure developed, Kubota started to release not only iron pipes but also various kinds of water-related products, such as polyvinyl chloride pipes, valves, and pumps. This became Kubota’s starting point for its involvement in the water industry.

1950-1960s

Modernization and the Development of Larger Water Infrastructures Brought on by Rapid Economic Growth

From 1954 to 1957, during Japan’s economic boom known as the “Jimmu Economy,” industries’ technological innovations as well as modernization of facilities advanced, and the country entered a period of rapid economic growth. The development of water infrastructures also proceeded at a rapid pace, and, as the needs for related materials and products rose, the water supply industry started to thrive at the same time.

Iron Pipe, Valve

Challenge to Mass-Production of Large-Diameter Ductile Iron Pipes with Centrifugal Casting

As waterworks facilities grew in size, the demand for large-diameter water pipes increased. For the development of Japan’s water infrastructure, Kubota attempted to manufacture ductile iron pipes through centrifugal casting, which was considered a challenge at the time, to mass-produce long, thin, and wide-diameter pipes.

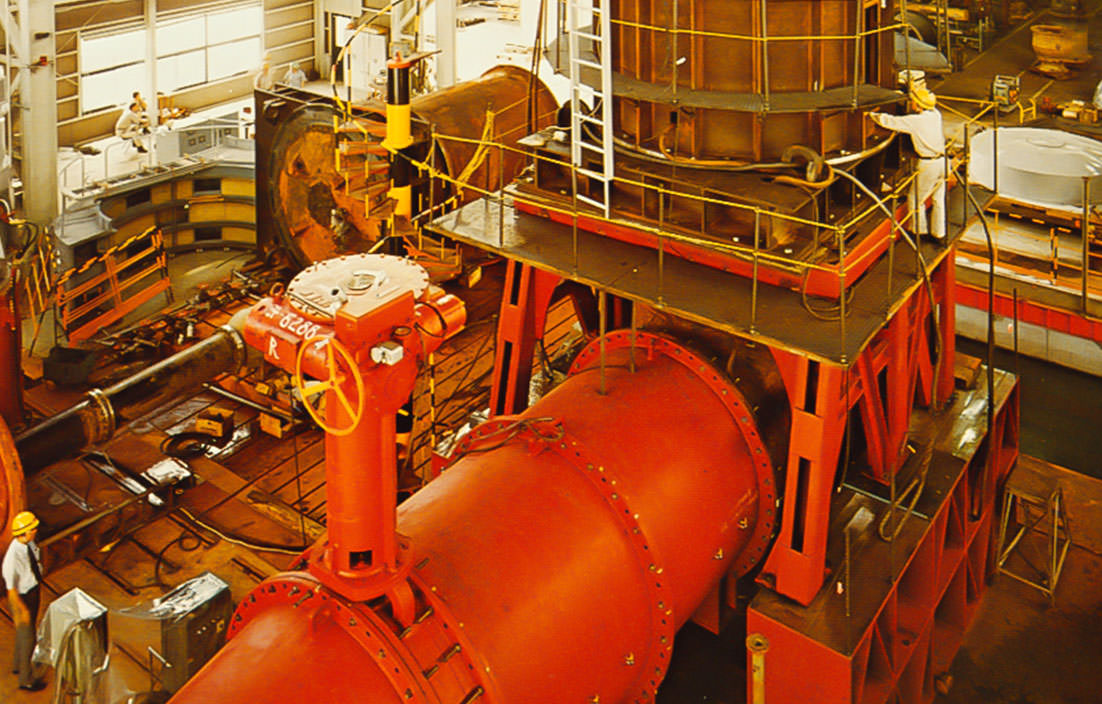

1960-1970s

The Heavy and Chemical Industries Develop as the Unprecedented Economic Boom Continued

The unprecedented economic boom caused by rapid economic growth brought on technological innovations and the development of the heavy and chemical industries. Large-scale infrastructure investments took place in the fields of oil, steel, and energy, and the demand increased for pipes, valves, and pumps, which were necessary to deliver water and other raw materials. In addition, their uses also diversified.

Valve, Polyvinyl Chloride Pipe, Pump

Valves and Pumps Diversified in Order to Support the Heavy and Chemical Industries

As the heavy and chemical industries developed, Kubota’s pipe system business entered the new fields of oil, steel, and energy. Its highly sophisticated technology started to be recognized abroad, as well.

1990s-

Developing Public Infrastructure in Preparation for Natural Disasters

Japan, which is an earthquake-prone country, constantly faces the threat of a major earthquake. In recent years, it has experienced tremendous damages with the Great Hanshin earthquake in 1995, the Tohoku earthquake and tsunami in 2011, and Kumamoto earthquake in 2016. In response, the implementation of earthquake countermeasures for public infrastructures, such as waterworks, has become an urgent task.

Iron Pipe, Valve, Polyvinyl Chloride Pipe, Pump

Providing a Reliable Lifeline by Accurately Grasping the Changing Needs

As earthquake countermeasures, Kubota has developed technologies for earthquake-resistant joints and pipeline layouts over the years. These technologies are steadily yielding results, continuing to protect valuable lifelines.