1890-1900s

Until the Production of Domestic Iron Pipes

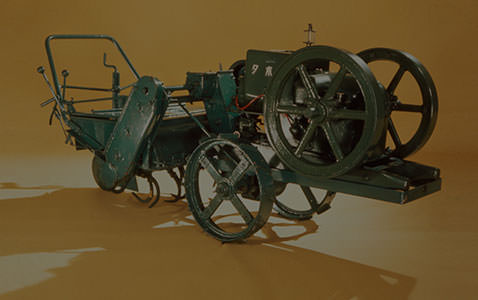

Standard Cast-Iron Pipe, Waterworks Valve

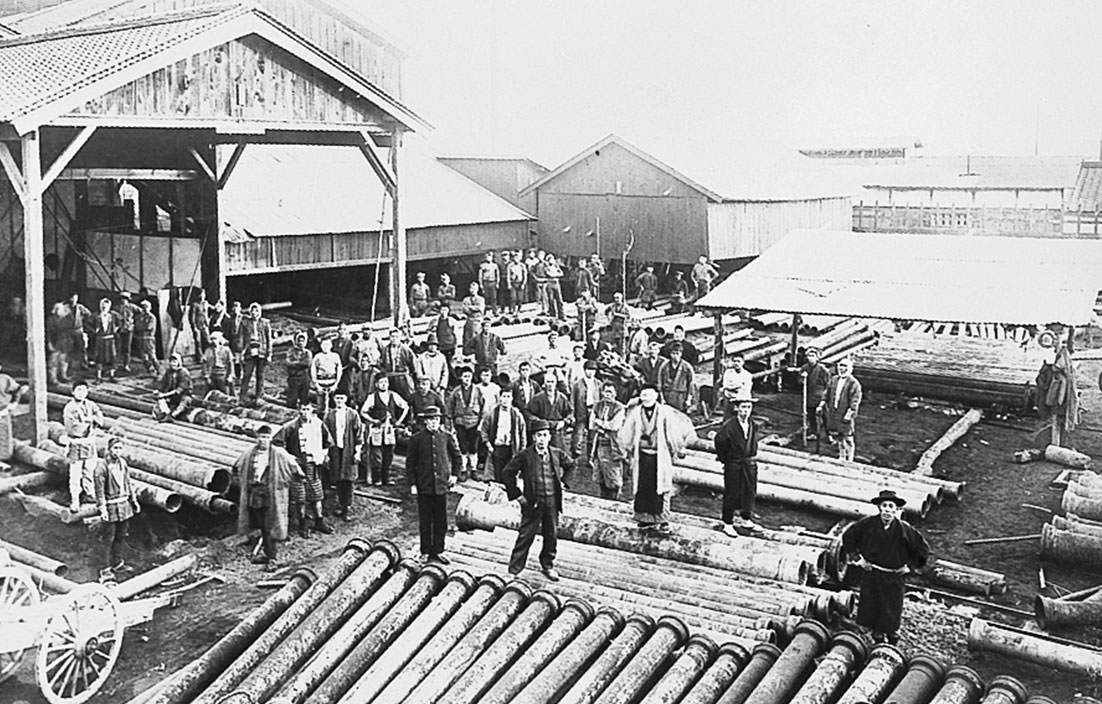

Shipment area for Kubota’s iron pipes around 1905

In order to contain infectious diseases, such as cholera, the government promoted the development of water infrastructure. Although Osaka City decided to employ domestic iron pipes and requested the Osaka artillery arsenal to cast the pipes, it was met with much difficulty. For the future of water infrastructure, as well as for the sake of public interest, founder Gonshiro Kubota, who was operating a casting factory at the time, started to domestically manufacture iron pipes for water works.

“What’s Possible for Foreigners Should be Possible for the Japanese’—A Strong Conviction Opens the Path for the Domestic Production of Water Pipes

At the time, all water pipes used in Japan were imported. Although different companies attempted to manufacture them domestically, all attempts failed. This was because thin-walled and long cast iron pipes tend to become uneven during casting and none had the know-how to produce pipes that were strong enough to endure high water pressure. However, with the strong conviction that “what is possible for foreigners should be possible for the Japanese,” Gonshiro repeatedly created prototypes and continued to make improvements for approximately 4 years and finally developed the “joint-type casting method,“ succeeding in the manufacturing of 10cm aperture straight pipes. The technique he developed through trial and error, without any literature or experience, gained others’ approval, and orders for iron pipes gradually increased.

Kubota started producing deform pipes in 1893. Four years later,

Kubota started producing deform pipes in 1893. Four years later,

it succeeded in manufacturing straight pipes.

“Kubota” Became Known for “Iron Pipes.” A New Technology Made Possible the Domestic Mass Production of Water Pipes

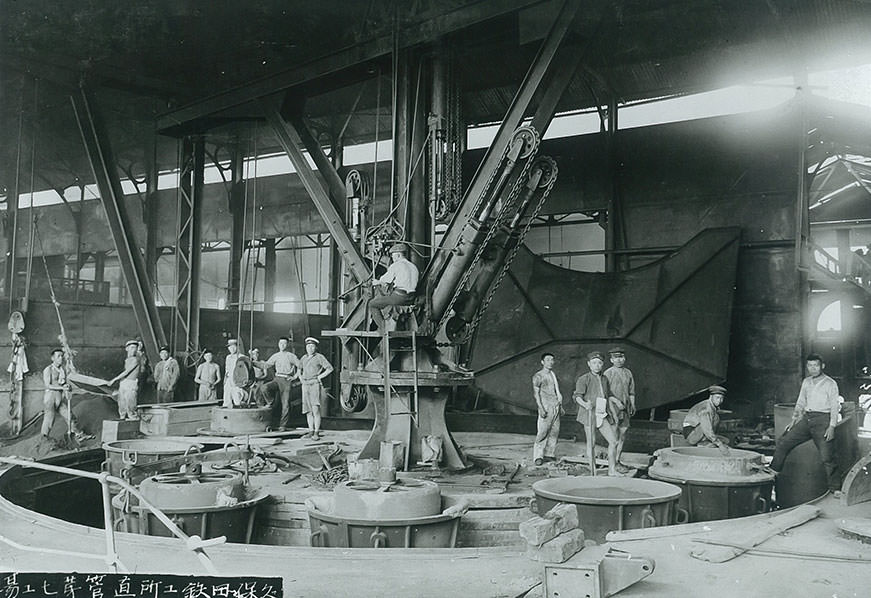

Although Kubota succeeded in manufacturing straight pipes using the “joint-type casting method“in 1897, its productivity was still low. It continued its research and development, and in 1990, it invented “the vertical round-blow casting method,” which enabled the steady production of “seamless iron pipes,” instantly increasing its product orders. Kubota’s iron pipes were used for Osaka City’s waterworks expansion project and gathered the industry’s attention. Furthermore, in 1904, Kubota invented the “vertical-blow rotary-type casting equipment,” which made possible the mass production of iron pipes, finally realizing the domestic mass production of water pipes for the first time. It established itself as “Kubota of Iron Pipes”—one of the few domestic iron pipe manufacturers.

Casting production line with the “vertical-blow rotary-type casting equipment,”

Casting production line with the “vertical-blow rotary-type casting equipment,”

which rotates a mold-mounted disk

Kubota’s Other Waterworks Supply which Grew Together with Iron Pipes, Along with the Spread of the Modern Water Infrastructure

Regardless of liquid or gas, valves “control flow” and are widely used in water infrastructure, as well as the steel, oil, and liquefied natural gas industries. This product and Kubota have a long history dating back to 1897. At the time, while Kubota struggled to create iron pipes for water work, it manufactured waterworks supplies such as sluice valves and fire hydrants. This was the start of Kubota’s valve manufacturing. With the development of modern water infrastructure since 1907, Kubota determined that sluice valves would be one of its major waterworks supplies together with iron pipes. Its production and sales grew, later becoming a part of Kubota’s pipe system business.

1940-1950s

Water Infrastructure is Restored, Overcoming Resource Shortages

The air raids during the final period of World War II destructed over 90 cities in Japan. After the war, the GHQ put great effort into hygiene measures, and water infrastructure rehabilitation was carried out at a rapid pace. Meanwhile, Japan had scarce resources, and manufacturers struggled to produce iron pipes, though restoration progressed little by little.

Scroll to See Next Story

1940-1950s

Started Developing Waterworks Supplies

—The Origin of Kubota’s Water-Related Business

Ductile Iron Pipe, Valve, Polyvinyl Chloride Pipes, Pump

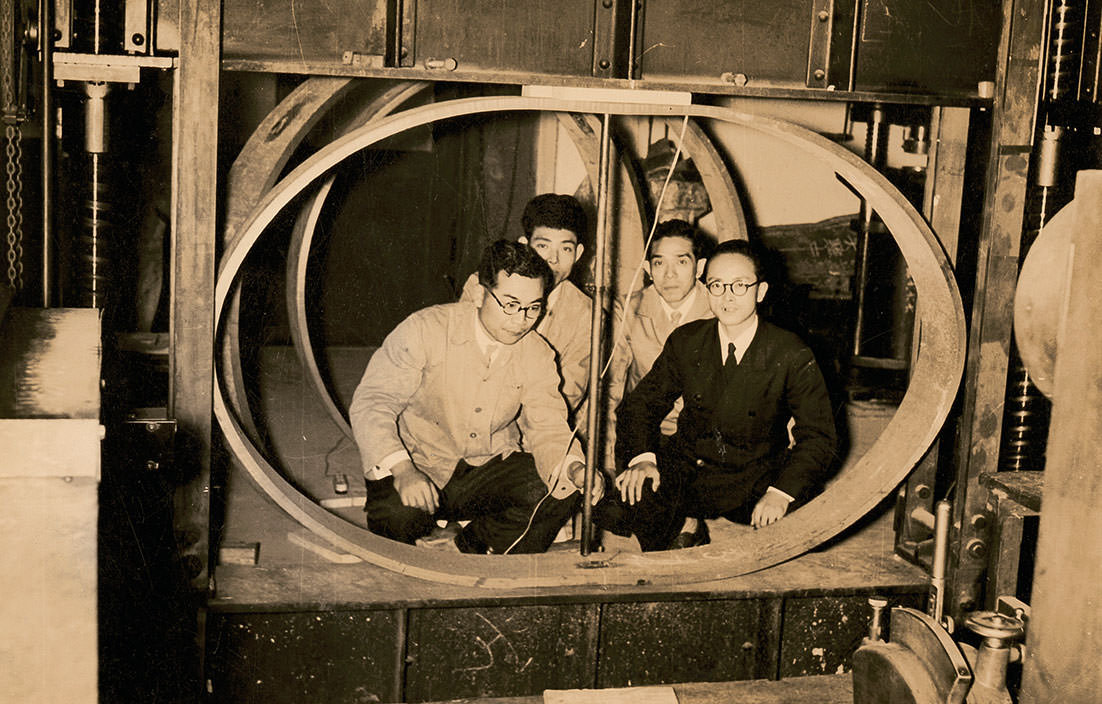

Conducting a strength test on the ductile iron pipe

As the country’s water infrastructure developed, Kubota manufactured and improved its iron water pipes and developed various water-related products, such as pipes made of materials other than iron, pumps that create water flow, and, valves that controlled the flow. This became the origin of Kubota’s water-related business.

The First in the East to Succeed in Developing the Metal Mold Centrifugal Casting Technology, Kubota Prepared for Mass Production of Iron Pipes.

As cities were reconstructed and demands recovered, Kubota prepared for the full-scale mass production of iron pipes. In 1949, it resumed its development of the “metal mold centrifugal casting method.” This made possible more successive use of the outer mold than the conventional centrifugal sand casting method. In 1950, Kubota was the first in the East to succeed in the production of pipes using this method by applying the “dry spray method,” in which ferrosilicon powder is sprayed to the metal mold interior. In the same year, this product was approved as the standard model by the Japanese Water Works Association and greatly contributed to the postwar reconstruction of cities. Furthermore, Kubota incorporated the “wet spray technology” introduced by the United States Pipe and Foundry Company, LLC. in 1952, further enhancing its product quality.

Kubota published the catalog of the metal mold centrifugal iron pipe

Kubota published the catalog of the metal mold centrifugal iron pipe

in both Japanese and English, looking into global marketing

The World’s First Application of Large-Diameter Ductile Iron Pipes Made Possible by a New Material and Kubota’s Tireless Effort

In 1948, a new material that shocked the industry was developed in the U.S. It was called the ductile cast iron (DCI) and had both the anti-corrosion quality of cast irons and the strength of a steel. This was a glimpse of hope for the large-diameter water pipe that Japan at the time sought for. Kubota immediately looked into this new material and started researching. Although it encountered unexpected hardships, Kubota diligently continued to research and succeeded in casting water pipes using the conventional “vertical-blow static casting method.” The nominal diameter 1200mm and 1350mm pipe that it supplied to the Hanshin Waterworks Municipal Association in 1954 became the world’s first application of the large-diameter ductile iron pipes.

Delivering the ductile iron pipes to the Hanshin Waterworks Municipal Association

Delivering the ductile iron pipes to the Hanshin Waterworks Municipal Association

Kubota Started to Develop Polyvinyl Chloride Pipes. Aiming to Be an All-Around Pipe Manufacturer, It Began Working with Materials Beyond Iron

The share of Kubota’s iron pipes, which constituted its core business, started to decline due to the rise of such alternative products as steel pipes and vinyl chloride pipes. Vinyl chloride pipes were resistant to chemical corrosion, lightweight, durable, and easy to lie out, and quickly spread for use at small-scale water supply systems and chemical plants. In 1954, Kubota determined to become an all-around pipe manufacturer and started to produce non-iron pipes, including vinyl chloride pipes. This year, the Tokyo Metropolitan Government Waterworks Bureau decided to adopt vinyl chloride pipes, and its demand rose exponentially. In 1955, Kubota ranked equally with the first 3 forerunners of the industry and received approval as a JIS specified plant for general industrial use.

Vinyl chloride pipe prototyped with the unit 1 pipe manufacturing machine

Vinyl chloride pipe prototyped with the unit 1 pipe manufacturing machine

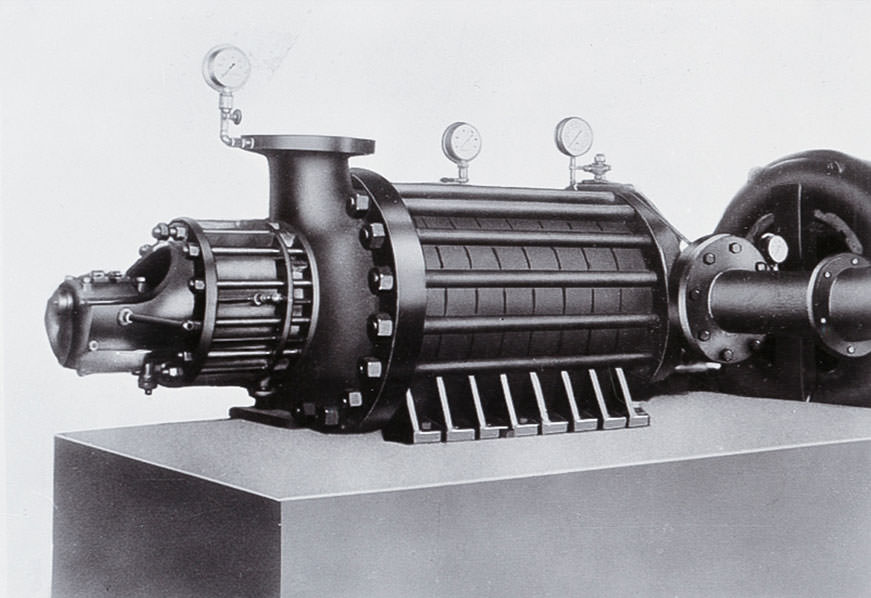

The 750 horsepower boiler supply turbine pump delivered

The 750 horsepower boiler supply turbine pump delivered

to Kansai Electric Power Company’s power plant in port of Shikama

Commercialized Pumps with the Aim of Expanding the Water-Related Market. Kubota Opened its Future in the Market Dominated by Large and Strong Competitors

In 1952, Kubota officially entered the pump industry with the aim of expanding its water-related business. The first order was a 750 horsepower boiler feedwater turbine pump from Kansai Electric Power Company’s power plant at port of Shikama. However, as leading, manufacturers were ahead in the pump market for both public and private demands, Kubota focused not on the then mainstream turbine pumps but on the development of compact volute pumps, cultivating its technique and accumulating know-how and achievements. It was after 1960, when demand for large pumps increased due to the rise in urban population, that Kubota, who entered the market later, started to thrive in this industry.

1950-1960s

Modernization and the Development of Larger Water Infrastructures Brought on by Rapid Economic Growth

From 1954 to 1957, during Japan’s economic boom known as the “Jimmu Economy,” industries’ technological innovations as well as modernization of facilities advanced, and the country entered a period of rapid economic growth. The development of water infrastructures also proceeded at a rapid pace, and, as the needs for related materials and products rose, the water supply industry started to thrive at the same time.

Scroll to See Next Story

1950-1960s

Challenge to Mass-Production of Large-Diameter

Ductile Iron Pipes with Centrifugal Casting

Iron Pipe, Valve

Producing ductile iron pipes with centrifugal casting

As the coverage of water infrastructure increased, its facilities also increased in size. In order to increase the amount of water flow, demand increased for large-diameter water pipes. What Kubota challenged after commercializing ductile iron pipes was centrifugal casting, which made possible large-diameter pipes and their mass production.

Succeeded in Centrifugal Casting of Ductile Iron Pipes, Realizing Wider Diameter and Mass Production

With the “vertical-blow static casting method,” Kubota succeeded in the commercialization of ductile iron pipes in 1954. However, centrifugal casting was necessary to mass-produce long, thin-walled large-diameter pipes. Various factors went into the centrifugal casting of ductile iron pipes, and its complexity made research difficult. However, by analyzing and addressing each issue one after another, Kubota finally developed the “resin sand casting method” in 1956. This original system, which used a golden frame with silica sand and phenol resin compound enameled to its interior, enabled the production of large-diameter centrifugal ductile cast iron pipes, taking part in the spread of water infrastructure during the time of rapid economic growth.

Centrifugal casting of ductile iron pipes using resin sand

Centrifugal casting of ductile iron pipes using resin sand

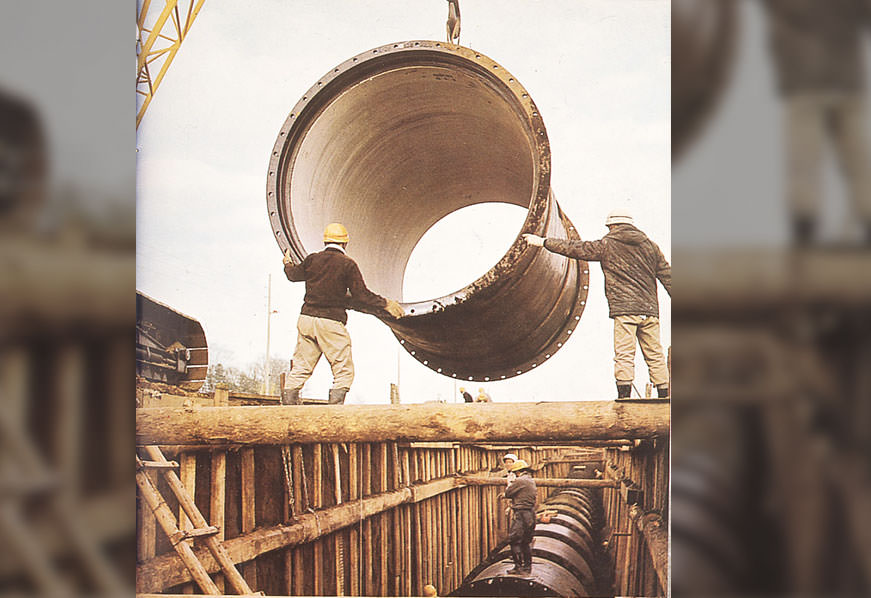

The Other Technology that Made Large-Diameter Pipes Possible. Kubota Developed an Improved and Innovative Mechanical Joint

Another factor that made possible the large-diameter pipes was the improvement in the joints that connect them. As the conventional spigot joints (type C) required time and experience installing them, Kubota, in 1954, started to domestically produce mechanical joints (type A), which were originally developed in the U.S. In the 1960s, it developed the improved mechanical joint (type K), which increased the water tightness for large-diameter pipe joints, and, under the direction of Tokyo Metropolitan Government Bureau of Waterworks, it developed the world’s first internal pipe joint (type U). It streamlined the process of construction work by enabling piping within shields and narrow trenches. These improvements led to the commercialization of extra-wide pipes such as the 2400mm pipe in 1964 and 2600mm pipe in 1971.

Laying the extra-large-diameter 2200mm ductile iron pipes

Laying the extra-large-diameter 2200mm ductile iron pipes

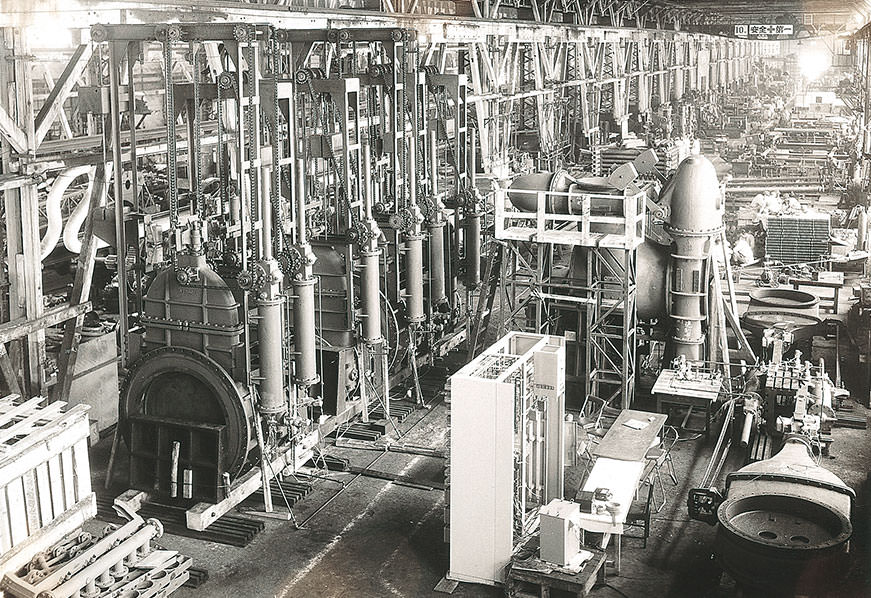

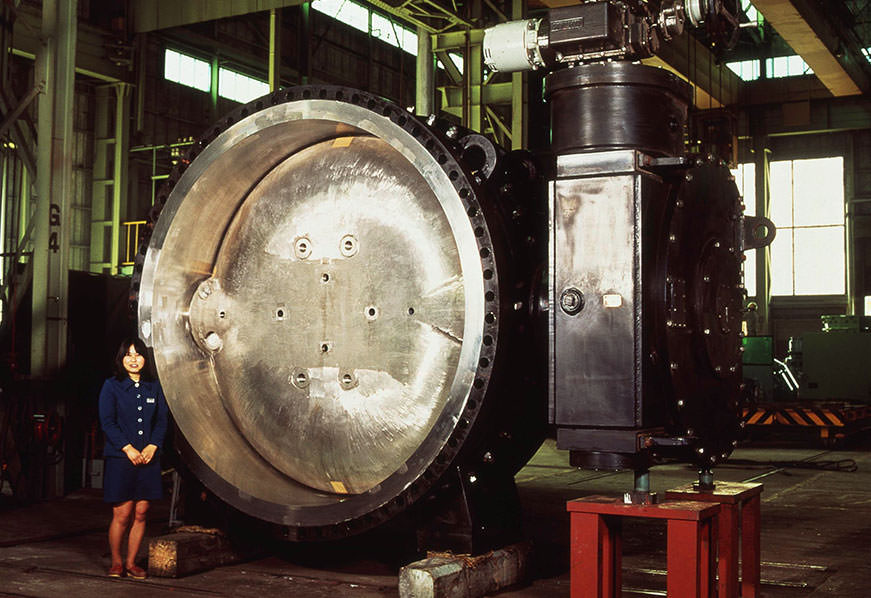

Entered the Electric and Steel Industries as a New Market for Private Sector Valve Demand

In the beginning of the rapid economic growth, in which Japan achieved industrial development, Kubota entered the electric and steel industries as a new market for valves in the private sector. In 1975, Kubota delivered 4000mm-wide seawater butterfly valves, which were the widest in the country back then, to the Kansai Electric Power Company. For the iron-making industry, Kubota succeeded in domestically producing an Hot Stove Valves in 1959. This device automatically controlled the amount of hot airflow that went into the furnace and was adopted at leading iron foundries around the country, along with the Fabricated Hot Blast Valve. At the time, together with the valves for the waterworks industry, valves for the steel industry became an important pillar that supported the valve business, as its use expanded.

Hot Stove Valves for iron foundries

Hot Stove Valves for iron foundries

1960-1970s

The Heavy and Chemical Industries Develop as the Unprecedented Economic Boom Continued

The unprecedented economic boom caused by rapid economic growth brought on technological innovations and the development of the heavy and chemical industries. Large-scale infrastructure investments took place in the fields of oil, steel, and energy, and the demand increased for pipes, valves, and pumps, which were necessary to deliver water and other raw materials. In addition, their uses also diversified.

Scroll to See Next Story

1960-1970s

Valves and Pumps Diversified

in Order to Support

the Heavy and Chemical Industries

Valve, Polyvinyl Chloride Pipes, Pump

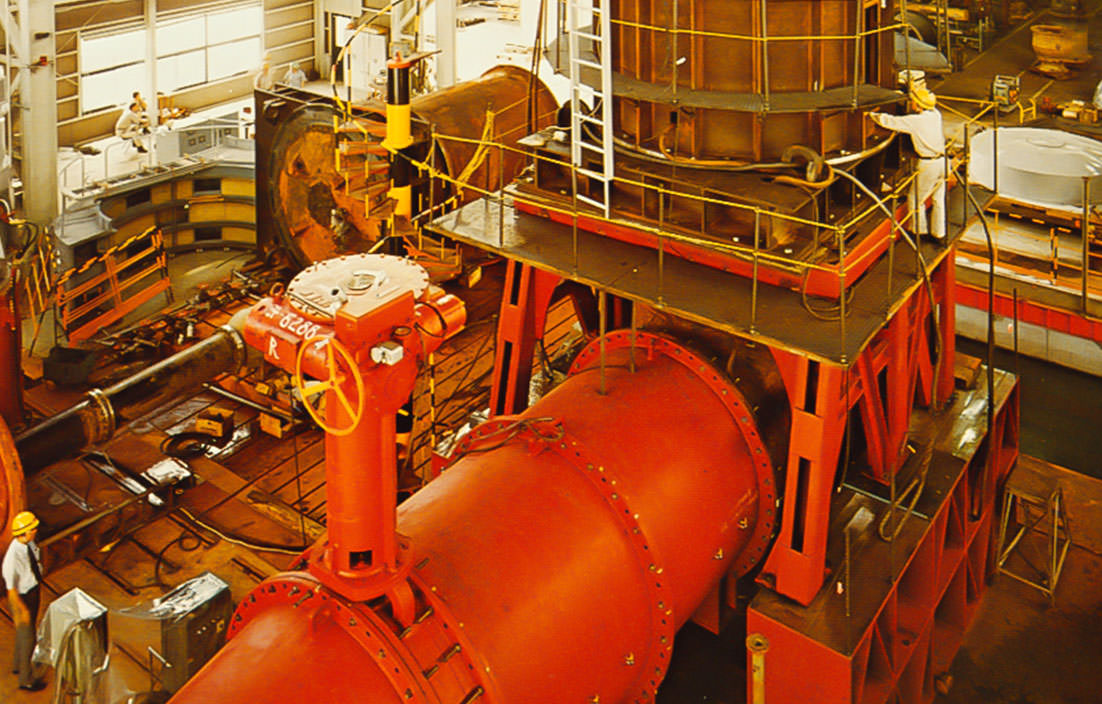

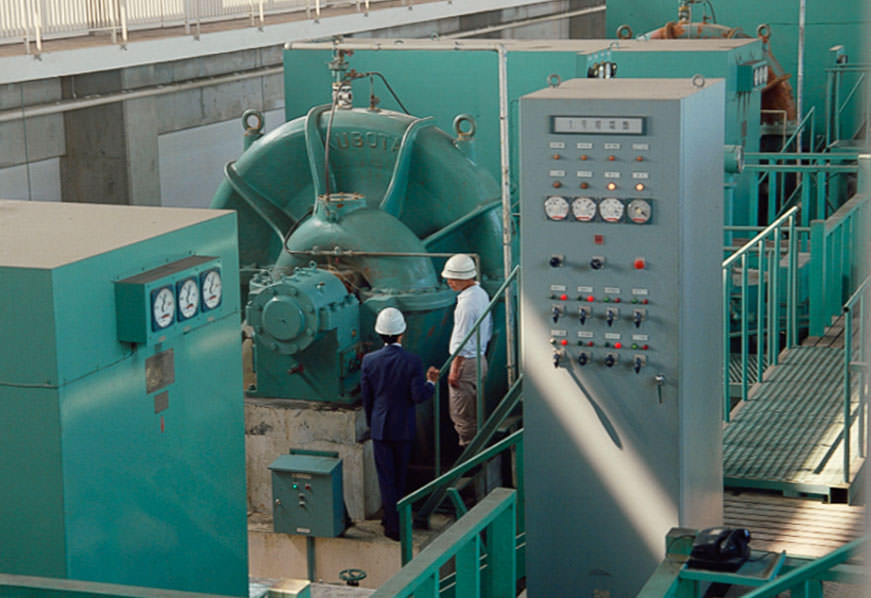

Trial run of seawater circulation pump delivered to Kyushu Electric Power

Kubota’s valve and pump products, which were mainly developed for waterworks, started to diversify as the heavy and chemical industries developed. They entered into the new market in the fields of oil, steel, and energy. The technology developed in these fields was widely recognized abroad, and business developed overseas, as well.

Started Producing Valves for Oil Refineries, Delivering Them to Overseas as Well

After the war, Kubota’s valves were supplied mainly to restore waterworks and liquefied natural gas facilities as well as to meet the demand from chemical fertilizer plants under the government’s policy to increase food production. However, as Japan entered a period of rapid economic growth, the valve business greatly developed. With major investments in infrastructure and great progress in technological innovations, the heavy and chemical industries developed, and the domestic production of petroleum products was realized. With this, Kubota developed slide valves and plug valves for fluid catalytic cracking units (FCC) in oil refineries at the Hirakata plant in 1970 to enter the energy market. Not only did it manufacture for domestic demand but also supplied to various countries overseas, including France and the Soviet Union.

The fluid catalytic cracking units, which is used

The fluid catalytic cracking units, which is used

during the oil refining process, developed in 1970

The Improvement of Waterworks Valve Technology. Kubota’s Highly Advanced Technology is Recognized, Receiving Product Orders from Abroad

Waterworks valves diversified, and butterfly valves and sleeve valves started to spread. In 1971, Kubota for the first time delivered sleeve valves, which excelled in flow and pressure control, to the Southern California Department of Water Resource. In 1972, it received an order from New York City’s water supply system for stainless metal seated butterfly valve to control Water Tunnel No. 3. This product had to last 100 years and was only delivered after much trial and error developing it. Based on the know-how it gained during this time, Kubota developed the ductile metal sheet butterfly valve for waterworks. This valve, which combined the advantages of a sluice valve and a butterfly valve, opened a new area in the field of waterworks valves.

The 2400mm stainless metal sheet butterfly valve that was delivered

The 2400mm stainless metal sheet butterfly valve that was delivered

to New York City’s water supply system

Kubota’s Pipe Technology that Greatly Contributed to the Spread of Diversifying Vinyl Chloride Pipes

Vinyl chloride pipes, which were initially developed for waterworks, quickly spread to the areas of industry, agriculture, construction, etc., as it was lightweight and easy to install. By improving its joints, Kubota established its place as an industry leader. However, as its use expanded, high-level jointing as well as ease of handling became more valuable in time. In order to respond to these demands, Kubota improved the rubber ring jointing method that was developed in Europe. In particular, the pipe that was developed in 1975 for the main sewer line did not have any level difference in the interior of the jointed section, preventing waste accumulation. This product was certified by the Japan Sewage Works Association standards and became the industry standard.

SGR-C Vinyl Chloride Pipe, which became the standard

SGR-C Vinyl Chloride Pipe, which became the standard

for main public sewer line pipes

Increasingly Remote Water Sources and Wastewater Infrastructure Development Projects Lead to Demand for Larger Pumps from the Public Sector

As cities grew, the sources for potable as well as industrial water could no longer be within the proximity of the cities. As the distance of water conveyance grew, large-diameter and higher head pumps were required. Kubota responded to this request, and, beginning with the delivery of one of the nation’s top class 3,100kW double-suction volute pump to Shizuoka Prefecture Department of Municipal Enterprise in 1970, it received orders for large pumps one after another. In addition, since the government issued the 3rd Five-year Sewer System Development Program, wastewater and rainwater drainage pumps increased in capacity, as well. Kubota steadily built a track record with the delivery of the vertical shaft volute type mixed flow pumps to the Kyoto City Fushimi Treatment Center, the development of the adjustable vane type pumps, which adapted to a wide range of water level fluctuation, and more.

The then nation’s top class 3,100kW double-suction volute pump delivered

The then nation’s top class 3,100kW double-suction volute pump delivered

to Shizuoka City Department of Municipal Enterprise

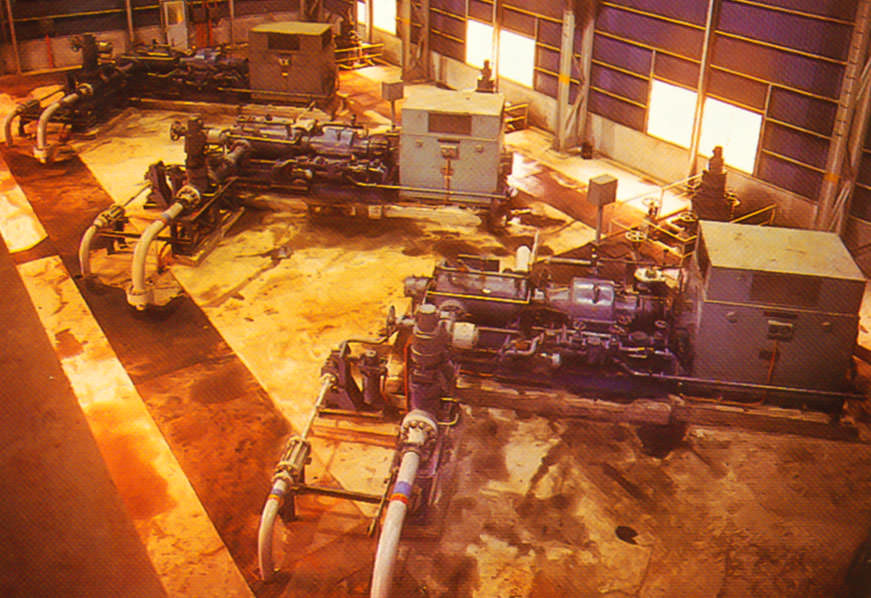

The Development of the Heavy and Chemical Industries. Kubota Signed Technological and Business Partnerships Abroad. Private Sector Pump Demand Diversified.

The demand for pumps in the field of oil, steel, and energy increased with the development of the heavy and chemical industries under rapid economic growth. Kubota’s private sector pumps were mainly developed for the steel industry building blast furnaces. In 1971, it delivered the high-pressure descaling pump, which was one of the largest at the time, to Sumitomo Metal Industries and developed various main pumps for the steel industry. In the field of energy, it signed a technological partnership with the West German Hallberg Maschinenbau GmbH for boiler feedwater pumps in thermal power stations in 1970 and a business partnership with the Bingham Company, U.S.A. for light water nuclear reactor pumps in 1973. Thus, Kubota diversified its products and expanded its market.

Descaling pump delivered to Sumitomo Metal Industries

Descaling pump delivered to Sumitomo Metal Industries

1990s-

Developing Public Infrastructure in Preparation for Natural Disasters

Japan, which is an earthquake-prone country, constantly faces the threat of a major earthquake. In recent years, it has experienced tremendous damages with the Great Hanshin earthquake in 1995, the Tohoku earthquake and tsunami in 2011, and Kumamoto earthquake in 2016. In response, the implementation of earthquake countermeasures for public infrastructures, such as waterworks, has become an urgent task.

Scroll to See Next Story

1990s-

Providing a Reliable Lifeline

by Accurately Grasping the Changing Needs

Valve, Polyvinyl Chloride Pipes, Pump

Test construction of earthquake-resistant pipe GENEX in Los Angeles, after being recognized as highly seismically resilient

Kubota has been working on earthquake countermeasures, developing the technology for earthquake-resistant joints, and establishing earthquake-resistant piping layout, etc. During the past major earthquakes, it demonstrated high seismic resilience, protecting an important lifeline and contributing to the prompt recovery of the foundation of people’s lives. Its performance not only received attention from Japan but also from abroad.

Striving to Realize “100% Earthquake-Resistant Pipelines.” The High Earthquake-Resilient Ductile Iron Pipe

In Japan, where active faults spread like a net, it is an urgent task to remake its water pipe line earthquake-resistant in preparation for natural disasters the scale of the 2011 Tohoku earthquake as well as other important lifelines. In 1974, Kubota succeeded in the development of first earthquake-resistant ductile iron pipe (S type) in the world. As the joint has the performance of expansion/contraction, deflection and anti-pull out structure, it can absorb the large ground displacement and prevent the joint from pulling out. In 2010, Kubota developed GX type earthquake-resistant pipe. It is characterized by its ease of installation and 100-year service life with high resistance to earthquakes

Pipeline suspension test for Kubota’s earthquake-resistant ductile iron pipes.

Pipeline suspension test for Kubota’s earthquake-resistant ductile iron pipes.

The joint section flex considerably, preventing detachment

New Earthquake-Resistant Valves—the Key to Strengthening the Seismic Resilience of Pipelines

Not only water pipes but also valves, which control water flow, play an important role in making the pipelines earthquake-resistant. Kubota made the mechanical joint type of sluice valves typically used for waterworks earthquake-resistant, realizing the construction of a completely integrated earthquake-resistant pipeline. In addition to excelling in water tightness, the earthquake-resistant butterfly valves and earthquake-resistant resilient seated sluice valves greatly adjust to the movement of the earth and are designed so that they do not detach from the pipelines. In order to help promote earthquake-resistant water pipelines, Kubota continues to improve and increase its product lineup.

The BU-AG Type GENEX Butterfly Valve with outstanding seismic resilience

The BU-AG Type GENEX Butterfly Valve with outstanding seismic resilience

and corrosion resistance

Looking Into the Seismic Resistance of Polyethylene Resin, Kubota Developed Polyethylene Water Distribution Pipes

The Great Hanshin earthquake in 1995, which caused tremendous damage, prompted the reexamination of the earthquake resistance standards of various public infrastructures. After finding that no damages were done to the polyethylene gas pipes underground based on the damage assessment, Kubota looked into the seismic resistance of the polyethylene gas pipes and developed high-density polyethylene water pipes. The following year, it released the polyethylene water distribution pipe, “Super Tough Poly.”

Kubota Develops Various Key Pumps as a Rapid Response to the Recently Increasing Guerrilla Rainstorms

As damages caused by natural disasters, such as the guerrilla rainstorms in urban areas, has become notable in recent years, awareness and needs rose for disaster mitigation other than earthquakes. In order to realize quick drainage during a torrential downpour, Kubota significantly improved the startup of its stand-by operation pump Hu-BOMBA, which it introduced to the market in the 1980s, and developed the Hu-BOMBA MAX in 2009. Furthermore, it introduced to the market mobile drain pumps for disaster relief. It strived to manufacture significantly lighter pumps and developed an ultra-light pump with both large drainage capacity and portability. By expanding the application area and significantly reducing the time required to start draining, it reduced the risk of flood damage.

Hu-BOMBA MAX, which can operate in the two modes of air-water mixed

Hu-BOMBA MAX, which can operate in the two modes of air-water mixed

discharge operation and air-water switching operation

Kubota’s Technological Strength that Continues to Support Japan’s World-Class Water Infrastructure

Today, the waterworks facilities constructed during the rapid economic growth are deteriorating, and Japan faces many challenges from maintaining and updating these facilities to making them seismically resistant. Not only does Kubota contribute to the solution of these issues from a hardware perspective—through product and technological innovation—but also from a software perspective—by providing an IoT solution system, applying the latest information and communication technology. Thus, Kubota will continue to support Japan’s water infrastructure with the technological strength it has cultivated over 120 years since its founding.