Japan is said to be blessed with an abundant supply of fresh water compared to other countries. However, this myth is being shattered due to aging pipelines and supply cutoffs caused by pipe breakage in various parts of the country.

Kubota's long-term vision GMB2030 calls for new solutions in the fields of food, water, and the environment. In the field of water, Kubota aims to provide a water environment platform in order to build water-related infrastructure that is safe, dependable, and resilient. Why does an advanced country like Japan face such challenges in the development of its water infrastructure? How is Kubota working to solve these pressing issues? And how can Kubota change awareness toward water issues throughout society? We talked to Eiji Yoshioka, the General Manager of Kubota's Water and Environment Infrastructure Consolidated Division.

Reasons for Lack of Progress in Upgrades of Aging Pipes

Japan currently has a water supply coverage rate of 98%. It is one of the few countries in the world where people almost everywhere are blessed with this capability to turn on a tap and get drinkable water, which is a remarkable standard of living. However, in recent years there has been news about water pipes bursting and gushing out water, leading to supply outages that inconvenience residents.

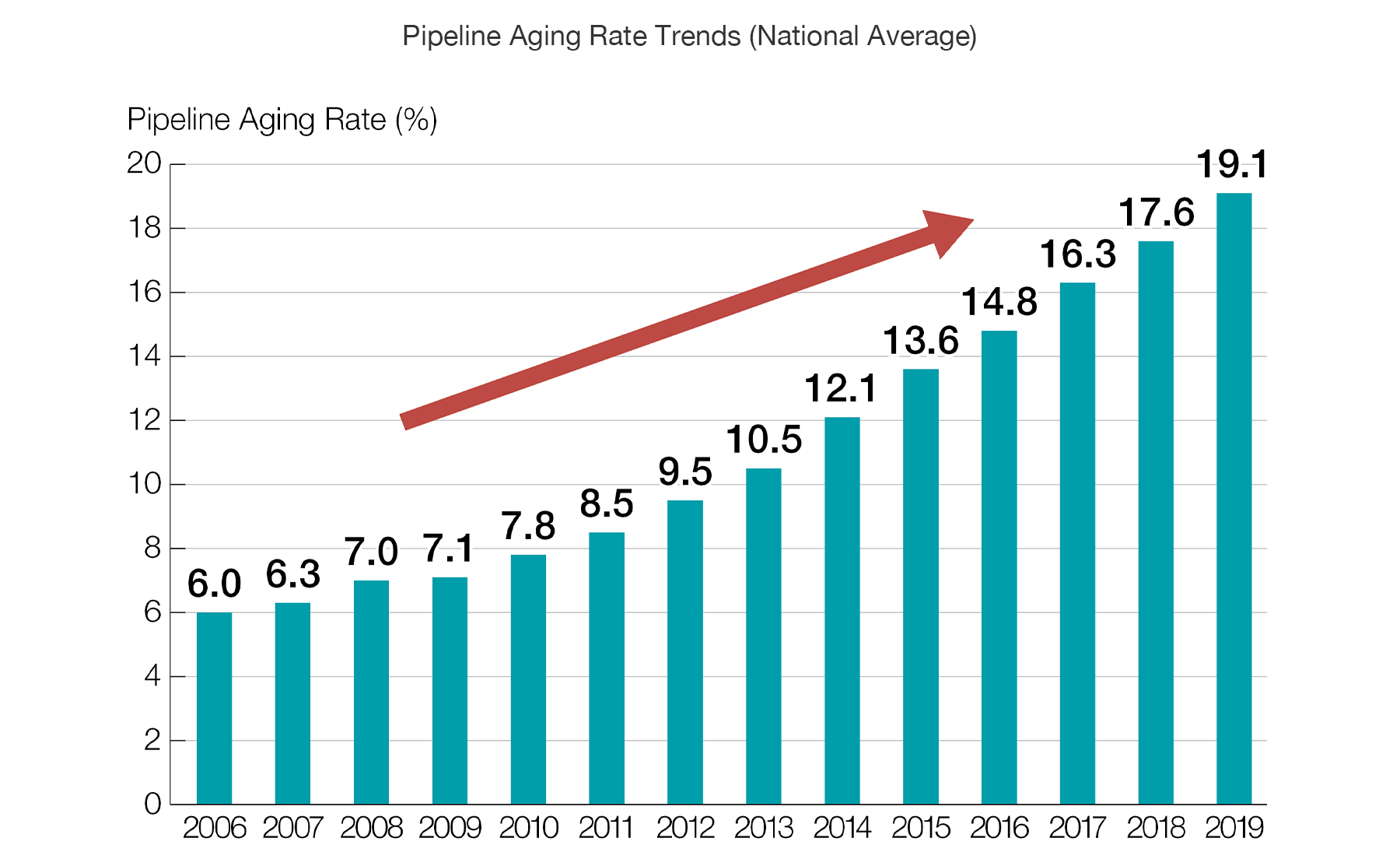

Most of the water pipes, treatment plants and other facilities in use throughout Japan today were constructed during the postwar economic growth period from the 1960s to the 1970s, and they are starting to deteriorate. Since water pipes have a useful life of approximately 40 to 50 years, all pipes are due for renewal around the same time, but progress on this work is lacking. What is more, floods caused by abnormal weather, earthquakes, and other natural disasters have become much more severe in recent years, which has also contributed to an increase in damage to water supply facilities.

Why has progress in upgrading water facilities not kept up with expectations? We talked to Eiji Yoshioka, the General Manager of Kubota's Water and Environment Infrastructure Consolidated Division, who has been involved in the water business for many years.

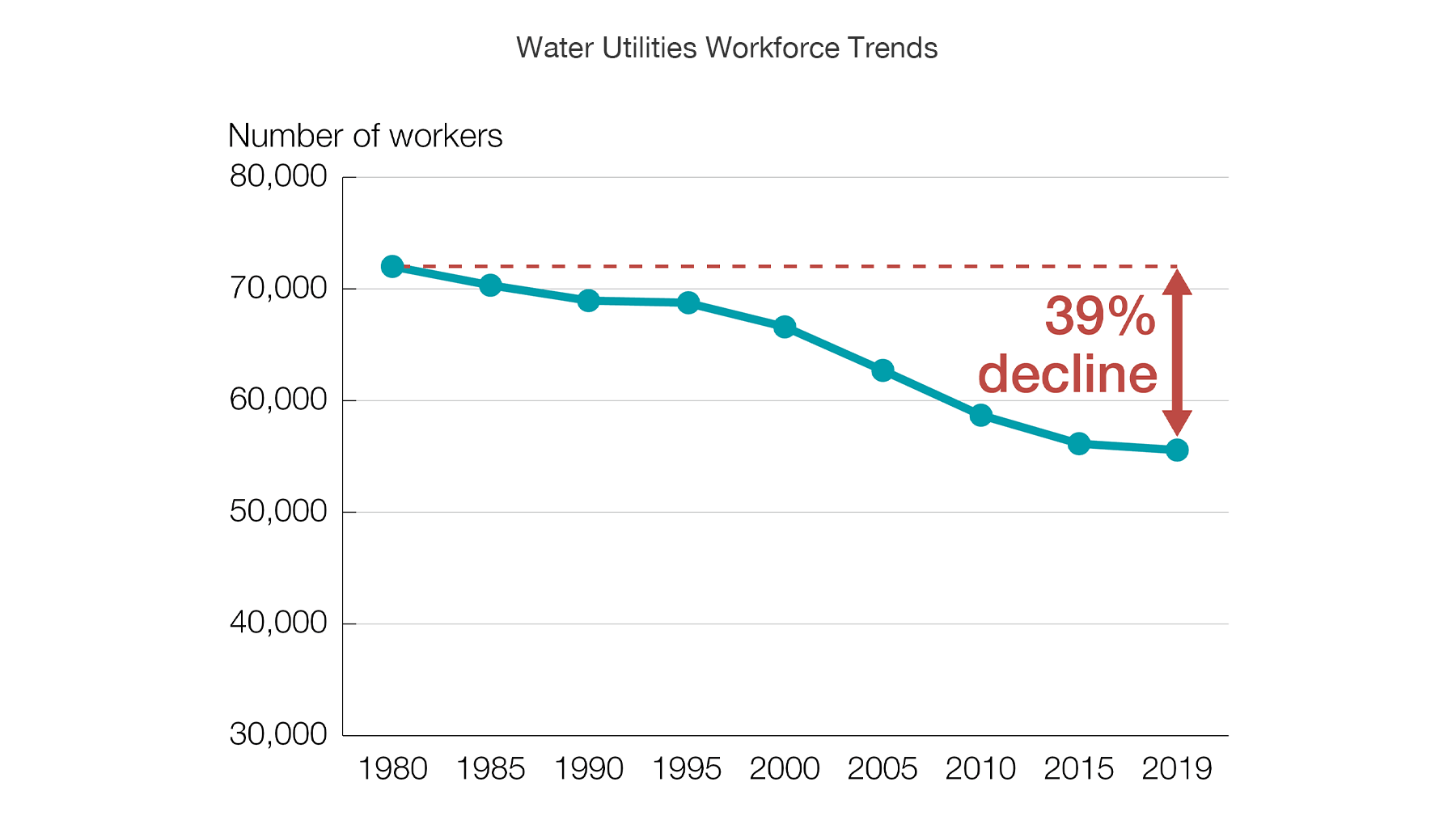

"The main reasons are the decline in revenues from water services caused by decreasing populations, and the decrease in the number of personnel involved in the water supply business. If the number of people using water services goes down, it is natural that less revenue is collected, which results in less money to spend on construction. The government is still budgeting funds for services, but the reality is that the work is not happening because there is a lack of personnel.

"Speaking of infrastructure that was built quickly during the rapid economic growth period, you probably know that expressways are also undergoing extensive upgrades. However, water pipes are buried underground and out of sight, and even though sewage treatment plants are above ground, the general public has almost no chances to see them. For these reasons, it is hard to make people conscious of water supply infrastructure, even though it is a public utility just like roads."

Public Private Partnerships and Digital Transformation are the Keys to Solving Problems

Yoshioka offers the following four goals in terms of the issues that Kubota is working to solve.

Kubota's Solutions to Japan's Water Supply Infrastructure Issues

- Make water utility operations more efficient (area expansion/public-private partnerships)

- Save labor and reduce workloads for operation and maintenance of water supply infrastructure (smart operation through automation and remote monitoring)

- Provide appropriate maintenance and upgrade proposals to reduce life cycle costs for facilities

- Make pipelines and facilities stronger and more earthquake resistant (improving resilience of infrastructure)

"In recent years, there has been greater movement toward Public Private Partnerships (PPP), in which local governments outsource the water treatment and sewage plant operation and management work that they had been doing to private firms, and Kubota is receiving more orders each year. One of the major trends has been for municipalities to enhance their own efforts with additional wisdom from the private sector, thereby reducing life cycle costs as much as possible and returning those funds to their citizens.

Along with its PPP efforts, Kubota is focusing on applying digital transformation to water utilities. One example is monitoring to check for leaks and changes in water quality. This is mainly performed by humans, but a digital transformation would make it possible for facilities and pipeline maintenance and management work to be done by fewer people. What is more, the use of the KUBOTA Smart Infrastructure System (KSIS), Kubota's exclusive IoT-enhanced solution system, enables analysis of wide-ranging data from water treatment plants, water pipes, sewage treatment plants, pumping stations, and other facilities using AI to catch signs of failure throughout the system.

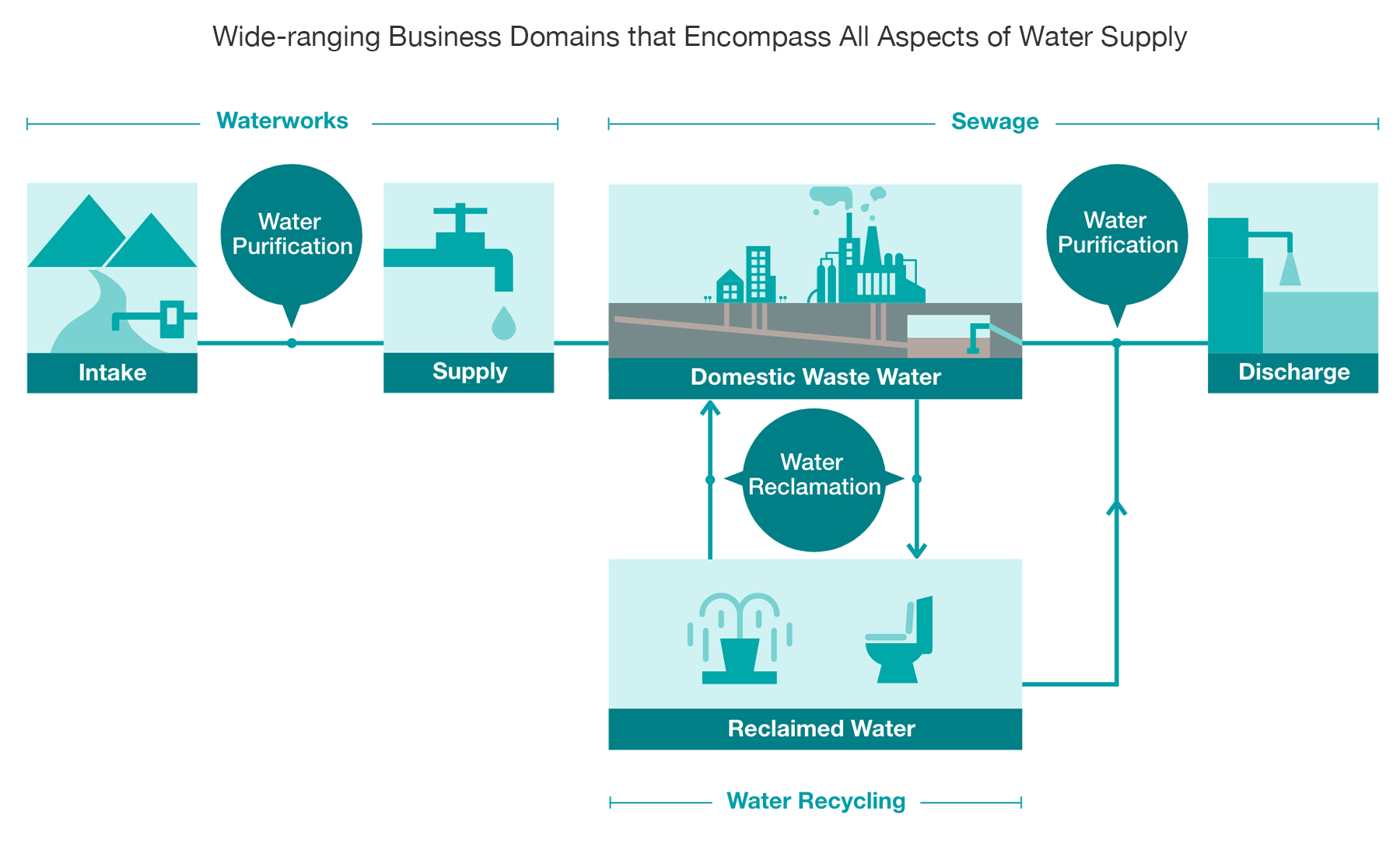

"Most people think of agricultural machinery when they think of Kubota. But 130 years ago, the company's founder Gonshiro Kubota sought to commercialize iron water pipes to stop the cholera epidemic, and he succeeded in mass-producing water pipes for the first time in Japan. This means water supply is the business our company was founded on. Kubota was also one of the first companies to introduce earthquake-resistant pipes to the world, and in addition to ductile iron pipes, Kubota makes plastic pipes, pumps, and valves along with equipment for purification and sewage treatment plants. On top of this, the company has a proven record in water infrastructure construction both in Japan and overseas. These combined capabilities that Kubota has developed throughout its history serve as its greatest advantage."

Left: In 1893, Kubota began manufacturing cast iron pipes. Four years later, the company succeeded in manufacturing straight pipes.

Right: Test installation of the GENEX earthquake-resistant ductile iron pipe in Los Angeles, U.S.

However, Yoshioka says that the company has not always been able to fully utilize these combined capabilities.

"In the past, Kubota provided its products to customers such as local governments and businesses according to their individual needs. But current needs require governments to utilize the knowledge of private companies, and in response Kubota aims to contribute to the world by mobilizing all of its product capabilities, knowledge, and engineering expertise, and fleshing them out with DX and IoT."

Examples of Two New Solutions Kubota is Pursuing

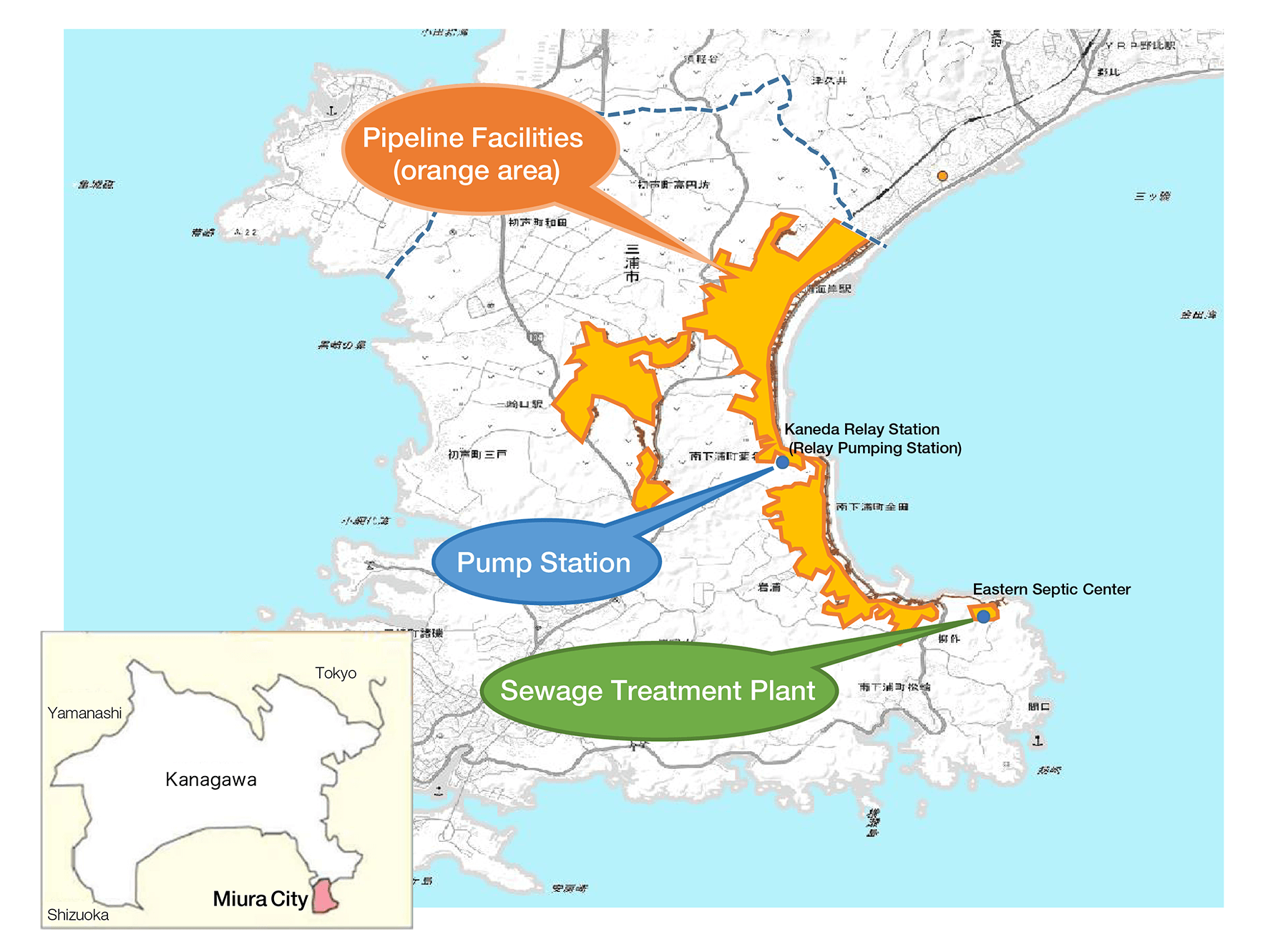

So, what specific initiatives are being worked on? In terms of the latest examples of PPP, Yoshioka mentioned Kubota's participation in the Miura City Public Sewerage (Eastern Treatment Area) Operation Project in Kanagawa Prefecture. This project has gained attention as it marks the first such project in Japan where all public sewerage facilities, including treatment plants, pumping stations, and pipelines, are operated, managed, repaired, and renewed under a concession system*.

- * A concession system is one in which the local government retains the ownership of the facilities while operating rights are given to a private operator. Multiple private companies set up a special purpose company (SPC) to manage the project. In this case, an SPC formed by Maeda Corporation, Kubota Corporation, Toshiba Infrastructure Systems & Solutions Corporation, Nihon Suikou Sekkei Co., Ltd., and Water Agency Inc. will operate the Miura City sewerage project for 20 years from 2023 to 2043.

Utilizing its many years of know-how in its water environment business, Kubota will contribute to the achievement of long-term, stable, and efficient operation of the city's sewerage projects and plans to demonstrate agricultural crop cultivation using the ground water heat discharged from the sewage treatment process. It will collaborate with educational institutions and other organizations in the city to select and cultivate crops and begin efforts that will help to revitalize the local community. This combination of agriculture and water businesses is a unique idea from Kubota that earned high praise in the competition. Seeing how it will develop in the future will be fascinating.

At the same time, Kubota is proactively utilizing open innovation to incorporate advanced technologies such as ICT and AI. In 2019, the company will set up Innovation Centers in Japan and Europe as divisions to promote creation of new business projects, products, and services, and it is moving forward with research and development in collaboration with outside partners such as start-ups, companies in other industries, universities, and research institutions. According to Yoshioka, who also serves as the Deputy General Manager of the Centers, a number of R&D projects that demonstrate Kubota's original approach are in currently in progress under the themes of resource circulation and building a new water infrastructure.

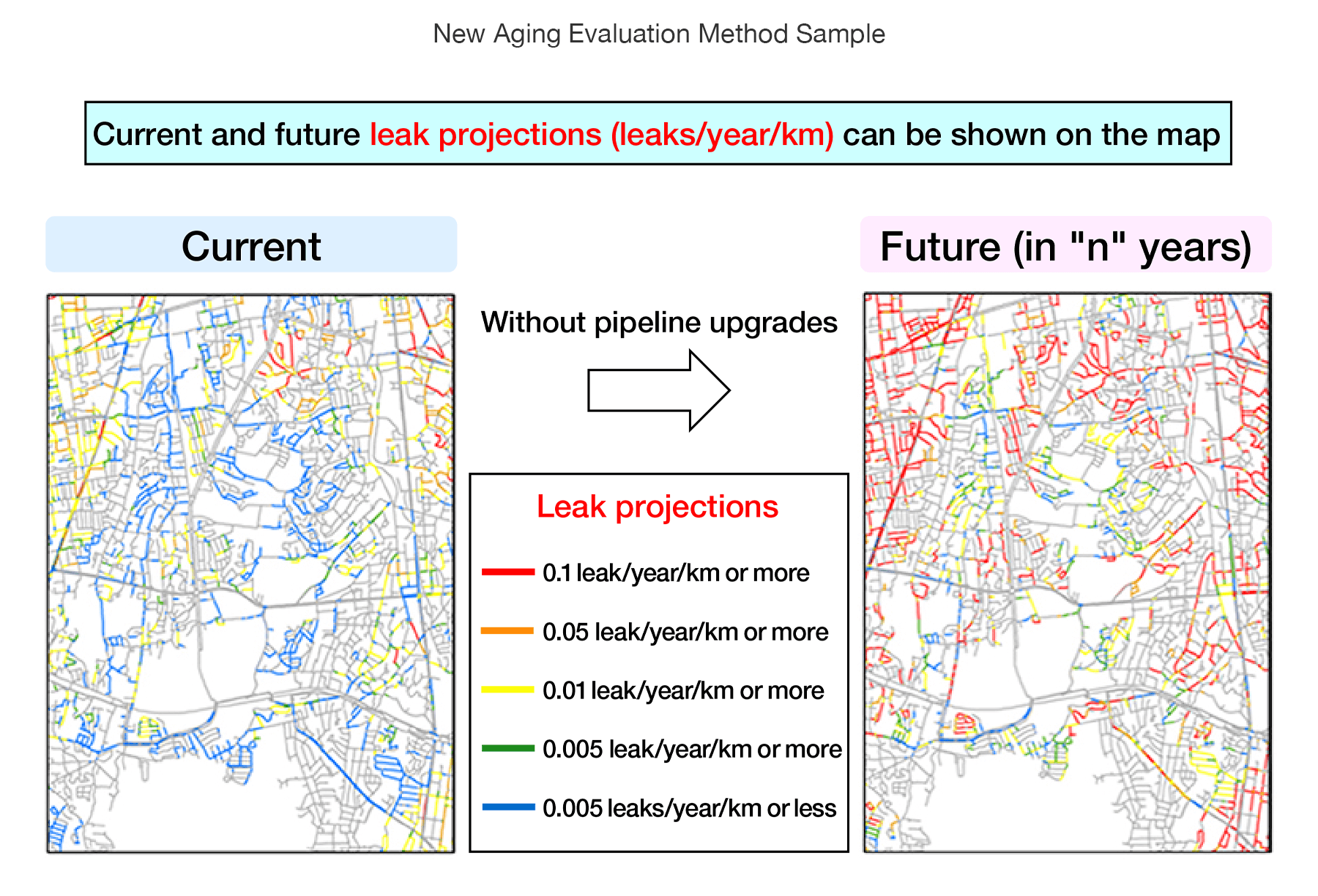

One joint project achievement is the water pipe aging evaluation method developed jointly with the University of Tokyo.

"In the past, when upgrades are done to aging water pipes, the degree of aging was simply evaluated based on the number of years, in the sense of replacing all pipes after 40 years. But actually, pipes age in different ways depending on where they are buried or the condition of their coating. For example, pipes naturally corrode faster if they are buried in highly acidic soil."

In other words, along with the degree of aging, future upgrades of water pipes can be conducted more efficiently if these factors are evaluated: resistance to natural disasters (presence of faults, frequency of earthquakes, etc.), water pathways and water quality, and importance of the waterway. On top of this, it will become more important to prioritize upgrades through a comprehensive evaluation that considers the municipality's policies for water utilities.

By building this new aging evaluation model, which combines Kubota's stock of survey data with AI technologies, the accuracy of aging forecasts has been drastically improved over previous ones. Kubota's group company Kansouken Inc. has already started using it in its pipeline diagnostic service, and it will likely be applied in other sites in the future.

Working toward a Society where Everyone is Conscious of Water

Considering what we have been told thus far, we got a renewed sense of the magnitude of the issues facing Japan's water utilities, and we wondered if there was anything individual water users could do to help. In response to this question, Yoshioka replied, "Let me pose a question to you. A 500ml plastic bottle of water costs about 100 yen. That means one liter is about 200 yen. So, what is the average rate in Japan for one liter of tap water?"

The answer is an astounding 0.2 yen. In other words, we are using copious amounts of drinkable water that costs 1/1000th the price of bottled water.

Yoshioka concluded the interview with these words.

"If nothing is done, water services could end up costing many times what they cost now. To sustain this society where people can use safe water as they please just by turning on their tap, and pass it on to our children and grandchildren's generations, the government and the private sector must make great efforts to maintain the water infrastructure, and this will cost a tremendous amount of money. We hope that everyone will understand the current situation and become more interested in water-related issues, so those of us who are involved in the Water & Environment business should become more proactive in spreading the message through various means. Water is essential for living, and I hope that everyone will consider water issues together and take action."

Mr. Yoshioka gave a simple and clear explanation of the issues involving water, which are difficult to grasp as a whole due to their breadth and depth. In particular, we were impressed by the new concession system in Miura City that Kubota is involved in, and this gave us a sense of the future possibilities. If such public-private partnerships keep developing, we will be able to make even greater efforts toward educating children on the importance of water, which could also reshape the next generation's awareness of water-related issues. We sincerely hope this leads to the building of sustainable societies that can provide safe and secure water to future generations.