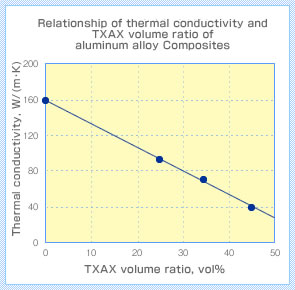

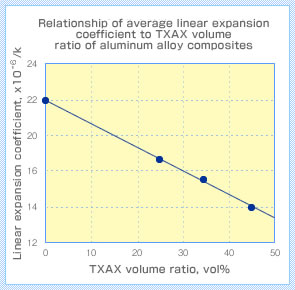

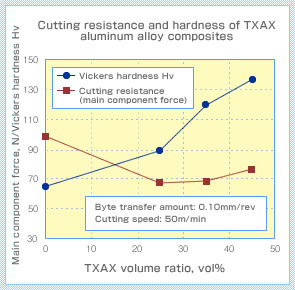

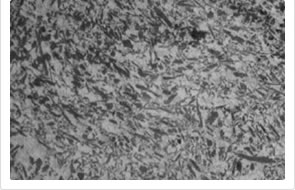

Against a background of environmental and energy problems, there is an increasing demand for reducing weight and downsizing components. In the field of metallic materials, high expectations are held for light alloys such as aluminum alloys. However aluminum alloys have restricted use due to having a large coefficient of thermal expansion and difficulties associated with regulating the thermal conduction ratio. Its improvement has been suggested by forming a composite with ceramic fibers, and potassium titanate displays several advantages in that regard including low thermal expansion, low thermal conduction and low hardness.

Kubota's potassium titanate differs from microfibers and has large size. Therefore the material enables high safety, excellent wettability with alloys and dispersibility in alloys.

After Kazunori Asano, Department of Mechanical Engineering, Faculty of Science and Engineering, Kinki University

Asano, K., et al. (2008) “Microstructure and Thermal Properties of Squeeze Cast Aluminum Alloy Composite Reinforced with Short Potassium Titanate Fiber,” Materials Transactions, Vol.49, No.11 (2008) pp.2664 to 2669

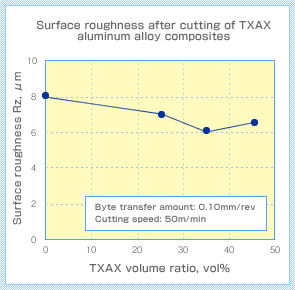

Asano, K., et al. (2008) “Machinability of Short Potassium Titanate Fiber Reinforced AC4A Aluminum Alloy Composite,” Materials Transactions, Vol.49, No.10 (2008) pp.2399 to 2404