HOME > Commodity > Performance for brake pads

TXAX is used chiefly in organic brake friction materials with a thermosetting resin. The materials are composed of fibrous materials, frictional modifiers (organic and inorganic filler, metal powder,solid lubricant) and binders.

TXAX has excellent properties required for brake pads such as physical characteristics (shape, low hardness), thermal characteristics (heat resistance, thermal insulating property), and chemical characteristics (friction interface responsiveness with principal components of Ti and K).

The above figure shows the results of evaluating the friction performance of brake pads made using TXAX. TXAX demonstrates stable friction characteristics and good wear resistance under various conditions.

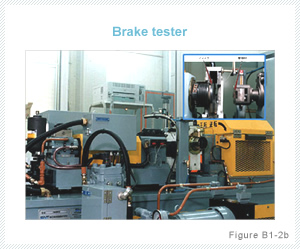

Kubota Corporation is developing high-performance materials by utilizing a 1/10-scale brake inertia dynamometer and evaluating friction performance under realistic braking conditions.

![]()