Industrial Steel Castings

Kubota's Cast Steel Products Contribute to Industrial "Creation"

To meet increasing demand for higher temperatures, higher pressures and larger sizes, equipment, components and parts for advanced steel manufacturing processes are required to possess high levels of functionality, stable quality, and reliability. Based on casting technologies perfected over many years, Kubota has established an integrated system that encompasses all processes, from materials research through manufacturing, inspection and engineering, and has developed numerous products with ideal characteristics and functions. We also have extensive experience in the area of industrial furnaces, including atmosphere furnaces and carburizing furnaces. Bringing together all of our resources in manufacturing, sales and engineering, we are committed to identifying and proposing solutions to the problems and challenges faced by our customers.

Kubota's Pursuit

Expertise in Many various Materials and Rich Experience in Casting

1. Expertise in Many Different Materials

We propose ideal steel casting materials for applications in industrial equipment operating under extreme conditions. We supply cast products with high resistance to heat, corrosion, and abrasion for various service environments and property requirements. We offer a broad range of materials based on our long experience and successful track record.

- Heat-resistant alloy:

- Having engaged in research and development of heat-resistant steels for more than 50 years since the 1960s, we recommend materials with the characteristics required for cast products, including heat resistance at high temperatures, oxidation resistance, carburization resistance, and thermal shock resistance.

- Corrosion-resistant alloy:

- Each alloy possesses specific corrosion resistance, high corrosion fatigue strength, and/or high resistance to stress corrosion cracking, and it holds special material properties where standard corrosion-resistant alloys are inappropriate.

2. Casting Processes

![[Melting]Melting:Not only carbon steels but also stainless steels, heat resistant and special high alloys are producible. We have various melting equipment which can cater to variations of materials, product sizes, and casting methods. [Casting]Centrifugal casting:In static casting, molten metal is poured into a mold and solidified to make a product. We can make cast products that are very thick or have complicated shapes, using casting plans based on our abundant experience.](/products/materials/products/steel_castings/img/img_process.jpg)

Products

Steel & Non-ferrous Metals Industry

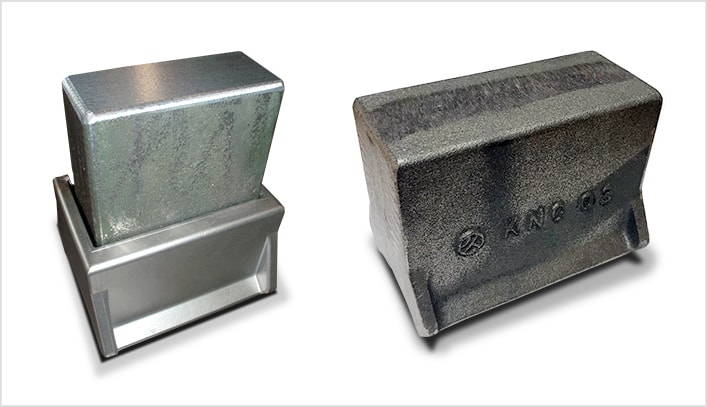

Skid Buttons

Kubota's Proprietary Ultra-high-temperature Material [KNC01, etc.]

Furnace parts called "skid buttons(riders)", which are used on the hearth of a slab reheating furnace in the steel manufacturing process, support steel slabs in an extreme environment exceeding 1,300°C; hence, they need to be made of a material which can withstand compressive deformation at high temperatures and is also resistant to oxidation. KNC01 (Cr-base) is a material developed using Kubota's original ideas and materials technology which boasts greatly superior performance compared to conventional Co-base materials.

Our skid buttons(riders) can eliminate temperature differences in the slab (skid marks) which could not be previously done, thereby improving quality of slab, heating furnace productivity, and energy efficiency.

We also offer conventional Co-base materials as well as eco-friendly Co-free products.

Kubota recommends materials and shapes that enable users to achieve the best performance under the specific furnace temperatures and service conditions of users’ operation.

Related Products

Materials Development

Materials which demonstrate ideal characteristics across a wide range of industrial fields in a variety of environments. Kubota develops and offers materials with the most suitable properties to meet customer needs, based on many years of experience, unique technologies, and solid success records.

Centrifugal Casting

We offer high-quality casting products that are restrained the generation of pinholes and inclusions in sizes to meet any outer diameter and length requirement. Kubota's centrifugal casting technology can realize multilayer casting products with different properties between the outer and inner surfaces.

Contact Us

To inquire about a product, service, maintenance, or any other matter, please contact your nearest Kubota location directly by phone or contact us by email. Before making an inquiry, we recommend that you check out our customer support information, including FAQs, as you might be able to find the answer to your question more quickly there.