LaqnicanJoint (Mechanical Joint)

LaqnicanJoint improves efficiency in piling work

Applications

- Bridge foundations

- Harbor structures

- River structures

- Earth retaining walls

Advantages

- Field Joint System Realizing Full-Strength Connection

-

Laqnican Joint can ensure full-strength connection without being affected by weather conditions or operator skills. (Steel pipes with Laqnican Joint have strength and deformation capacities equivalent or superior to those of steel pipes with no joints.)

→High-quality field connection is available - Rapidly Connects Pipes Having a Large Diameter and Wall Thickness

-

Connection work takes only a short time, regardless of pipe size. You can field-joint pipes of different thicknesses.

→Shortens the construction period - Easy Connection

-

Just fit one joint into another and tighten the bolts for pushing and fixing key. No special skills or qualifications are required.

→Anyone can connect pipes with ease - Easy Construction Quality Control

-

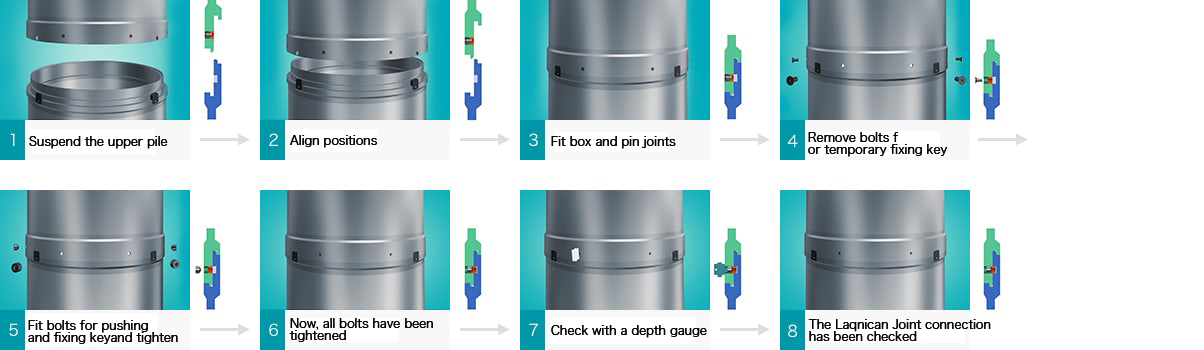

Just check the depth of tightened bolts for pushing and fixing key with a depth gauge. No special testing tools are needed for connection checks and work quality control.

→100% inspection of joint connections

Construction

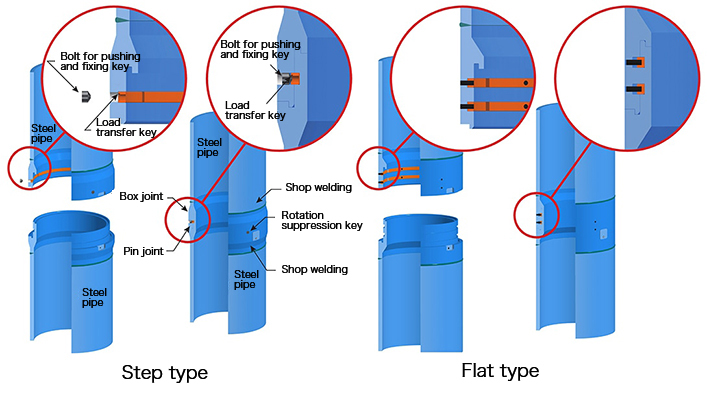

Laqnican Joint consists of a box joint, pin joint, load transfer keys, and bolt for pushing and fixing key. The box joint has one or more grooves in the inner circumference containing (circumferentially split) arc-shaped plates, called "load transfer keys." These keys are pushed toward the pipe center when the bolts for pushing and fixing key are turned. The pin joint has grooves on the outer circumference which are positioned to align with the box joint grooves.

To connect two steel pipes, set the box joint (which is circumferentially factory-welded to the upper steel pipe pile) onto the pin joint (which is circumferentially factory-welded to the lower steel pipe pile), and turn the bolts for pushing and fixing key to push the load transfer keys held in the box joint grooves into the pin joint grooves. This assembles all parts into an integral joint and completes connection of the two steel pipes. After assembly, Laqnican Joint connections can be 100% inspected by checking the depths of the tightened set bolts. Furthermore, a "rotation suppression key" on the outer surface transmits the rotational torque in the piling work. Where the impact driving or vibro-hammer method is used, a measure to control bolt for pushing and fixing key loosening (such as a stop ring) is used.

>> For more detail, please check Kubota’s technical report for Laqnican Joint(Mechanical joint)

Procedure & Advantages

- Laqnican Joint Shortens Operation Time

-

You need only:

about 5 minutes for field connection, and

about 3 minutes for quality control.Lately, steel pipe piles of large diameters and wall thicknesses are being used in a growing number of foundation designs. This means that welding operations account for an increasingly large proportion of the total working hours needed for construction. Taking only about five minutes for each connection, regardless of steel pipe diameter and wall thickness, Laqnican Joint can shorten the time required for connecting steel pipe piles and thus significantly reduce costs by shortening the overall construction period.

- Laqnican Joint Connection Procedure

-

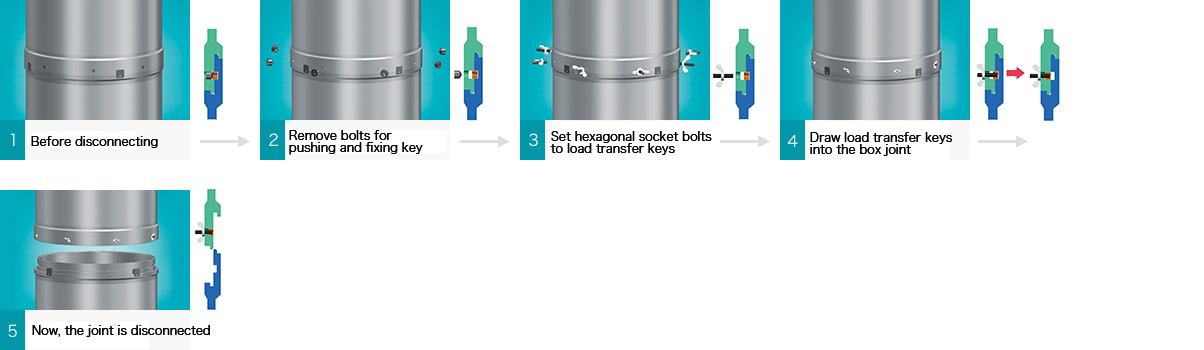

- Disconnecting a Laqnican Joint

-

Examples of Applicable Piling Construction Methods for Laqnican Joint(Mechanical Joint)

Impact driving construction method

Viblo-hammer construction method

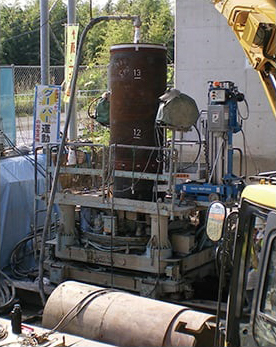

Steel-pipe soil-cement composite pile construction method

Rotary press-in construction method(360 degrees)

Rotary penetration construction method

Press-in construction method

Inner excavation construction method

Hydraulic full-slewing inner excavation consstruction method

Applicable Type of Construction for Laqnican Joint(Mechanical joint)

Harbor construction work

*A piling barge was used.

Railway construction work

*Nighttime work when trains have stopped running

Steel pipe sheet pile foundations

*Can be joined without a distance piace.

Using woter-sealant materials can further enhance the woter-sealing effect of Laqnican Joint.

Temporary platform pillars

*Used for platform pillars

Road construction work

*Where overhead clearance is small

Related Industries

Civil Engineering & Construction

Lately, as a part of protective measures against natural disasters, steel pipe piles have been getting increasingly larger, in both diameter and wall thickness. Our mechanical joints enable quick jointing of steel pipe piles and steel pipe sheet piles with no on-site welding required, which contributes to the realization of stable quality, shorter work periods, lighter workloads, and reduced construction costs.

Contact Us

| Steel Pipe Sales Dept., Tokyo Head Office | Kyobashi Trust Tower 1-3 Kyobashi, 2-chome, Chuo-ku, Tokyo 104-8307, Japan TEL.:(81)-3-3245-3259 FAX.:(81)-3-3245-3269 Email.kbt_g.steel-p_contact01@kubota.com |

|

|---|---|---|

| Ichikawa Plant | 4 Koya-shin-machi, Ichikawa-shi, Chiba, 272-0011, Japan TEL.:(81)-47-328-0171 FAX.:(81)-47-328-0177 |