Technology

Industrial materials are not only the raw materials for products that support human life but also vital for industries as component of manufacturing equipment. For Kubota, which started out in 1890 as a casting manufacturer, the industrial materials business may be called one of the origins of its operations. Starting with balance weights, Kubota succeeded mainly in the field of special steel casting products such as cast steel pipes, and steel pipe piles, which led to the company making major advances. From the 1980s, the company has also been developing industrial materials other than steel castings, using new materials and technologies, to meet the changing and expanding needs of the times and markets. Today, we make industrial materials, from structural materials to advanced new materials, for a broad spectrum of industrial fields, including petrochemicals and petroleum refining, steel and machinery, civil engineering and construction, and automobile, using our proprietary process technologies tailored for different applications. With a total commitment to meeting every different customer request and to pursuing study, we have developed technologies that make us an industry leader. Kubota's core technologies are used not only in materials research and development but also at several different points of manufacturing processes, including forming, molding, and processing. We can propose and supply the best industrial material products for your particular application from innumerable combinations of these, based on our know-how to achieve the purpose of the installation, even under the most challenging environmental conditions. Lately, expectation and demand for industrial materials have been further increasing both in Japan and overseas in line with the development of emerging economies. Always staying close to customers, Kubota will continue to support industry worldwide by offering high-value industrial materials which can contribute to improvement of quality, productivity and efficiency.

Core Technologies

Materials Development

Materials which demonstrate ideal characteristics across a wide range of industrial fields in a variety of environments. Kubota develops and offers materials with the most suitable properties to meet customer needs, based on many years of experience, unique technologies, and solid success records.

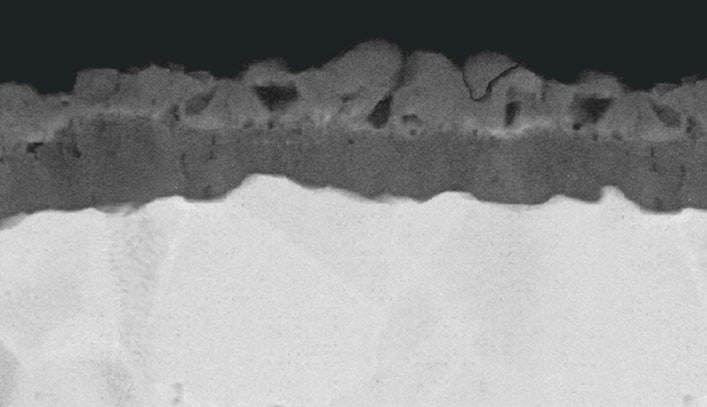

Surface Modification

Surface modification refers to giving a new function to a base material through altering the composition or structure of the material surface by applying a special treatment or process. Kubota has been meeting customer needs by combining its metallic materials technologies and surface treatment technologies to improve material performance.

Inorganic Materials Synthesis (Titanic Acid Compounds)

Titanic acid compounds have many useful material properties. Kubota, having the technical know-how to control crystal shapes, can offer them as large-diameter long fibers. Furthermore, through simultaneous utilization of synthesis and modification technologies, materials with new properties may be developed.

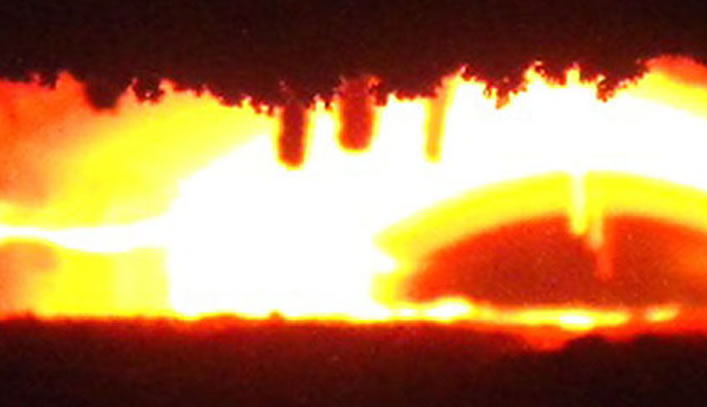

Centrifugal Casting

We offer high-quality casting products that are restrained the generation of pinholes and inclusions in sizes to meet any outer diameter and length requirement. Kubota's centrifugal casting technology can realize multilayer casting products with different properties between the outer and inner surfaces.

Contact Us

To inquire about a product, service, maintenance, or any other matter, please contact your nearest Kubota location directly by phone or contact us by email. Before making an inquiry, we recommend that you check out our customer support information, including FAQs, as you might be able to find the answer to your question more quickly there.