Inorganic Materials Synthesis (Titanic Acid Compounds)

Titanic acid compounds include materials with a wide variety of characteristics, such as barium titanate (known for ferroelectricity) and aluminum titanate (known for thermal shock resistance). Technologies for using titanic acid compounds are now being developed. Kubota has unique technologies, including one for producing specially shaped titanic acid compounds and another for synthesizing derivatives from chain architectures such as TiO6 octahedra, utilizing intercalation. A variety of properties achieved through integrating these technologies offer tremendous potential for future development of functional materials.

Core Technologies

Technologies to produce modificated titanic acid compounds

Plate-like calcium titanate "TXAX-CT"

The plate-shaped calcium titanate with large diameter and length, synthesized by combining the shape control technologies and the interlayer ion reaction technologies of Kubota Corporation

Physical properties of TXAX-CT

| Chemical name | Calcium titanate | |

|---|---|---|

| Chemical formula | CaTiO3 | |

| Color | Pale purple | |

| Size(μm) | Mean length: 50, Mean width: 12 | |

| Particle density(g/cm3) | 4.0 | |

| Bulk density(g/cm3) | 0.5 | |

| pH | 8~9 | |

| Moisture content(mass%) | < 0.2 | |

Examples of physical properties of TXAX-CT composite PPS

| Density(g/cm3) | 1.67 | 1.99 |

|---|---|---|

| Flexural strength(MPa) | 118 | 121 |

| Flexural modulus(MPa) | 5,170 | 10,640 |

| Dielectric constant 1MHz | 4 | 6 |

| Dielectric dissipation factor 1MHz | 0.002 | 0.004 |

| Dielectric constant 5GHz | 7 | 12 |

| Dielectric dissipation factor 5GHz | 0.003 | 0.003 |

Technologies to produce specially-shaped titanic acid compounds

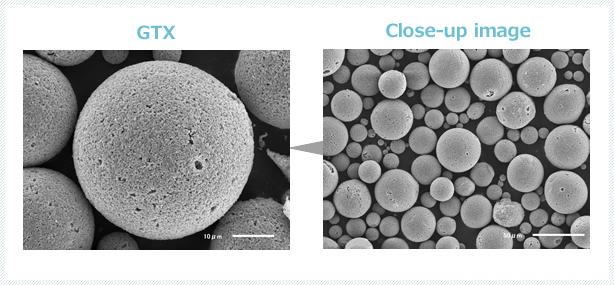

Porous titanic acid compounds "GTX"

The porous titanic acid compound particles that suppressed the growth of fibrous crystals of potassium titanate by adding the third component

Physical properties of GTX

| Chemical name | Potassium hexatitanate/Calcium titanate |

|---|---|

| Chemical formula | K2Ti6O13/CaTiO3 |

| Structure | Tunnel/Perovskite |

| Shape | Spherical |

| Size(μm) | Mean diameter:45 |

| pH | 8 |

| Specific surface area(m2/g) | 3.4 |

| Particle density(g/cm3) | 3.6 |

| Bulk density(g/cm3) | 0.9 |

| Melting point(℃) | 1310~1350 |

| Moisture content(mass%) | < 0.4 |

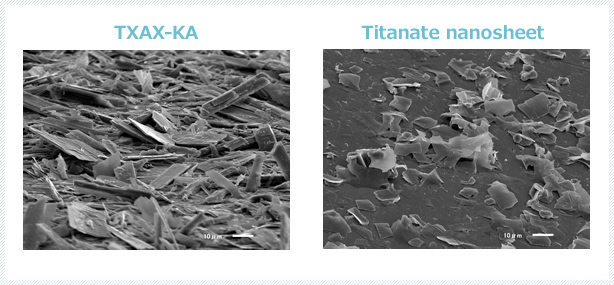

Flaky titanic acid compound "TXAX-KA" and Titanate nanosheet

The flaky titanic acid compounds formed by swelling and peeling between layers, using the ion exchange reaction and the intercalation reaction of the layered crystal

Physical properties of TXAX-KA

| Chemical name | Potassium hexatitanate |

|---|---|

| Chemical formula | K2Ti6O13 |

| Structure | Tunnel |

| Shape | Plate-like shape |

| Size(μm) | Mean length:45 Mean width:10 Mean thickness:(2) |

| pH | 8 |

| Specific surface area(m2/g) | 4.5 |

| Particle density(g/cm3) | 3.6 |

| Bulk density(g/cm3) | 0.2 |

| Melting point(℃) | 1310~1350 |

| Moisture content(mass%) | < 0.4 |

| Mohs hardness | 4 |

| Thermal conductivity(W/m・K) | 1.7(at760℃) * |

| Specific heat(J/kg・K) | 920(at400℃) |

| Linear expansion coefficient(×10-6/K) | 6.8 |

| Volume resistivity(Ω・cm) | 3.3×1015 * |

| Permittivity(ε) | 3.5~3.7 * |

* literature data

Related Products

TXAX

TXAX is a ceramic material supplied as large diameter long fibers having a plate-like shape. Possessing highly useful material properties such as high heat resistance, thermal insulation, and friction stability, its applications include friction materials in machines, reinforcing materials for plastic and metal products, coating materials, along with many other uses.

Related Industries

Automobile Industry

We process a wide variety of materials, from steel to plastics, using a range of technologies. Kubota's TXAX is a brake pad friction material that has less impact on the environment, favored by many users both within and outside of Japan.

Contact Us

To inquire about a product, service, maintenance, or any other matter, please contact your nearest Kubota location directly by phone or contact us by email. Before making an inquiry, we recommend that you check out our customer support information, including FAQs, as you might be able to find the answer to your question more quickly there.