Cracking Tubes (Cracking Coils)

Kubota's Pursuit

"Cracking Coil" -- A Vital Component in the Manufacture of Raw Materials for Plastics such as Ethylene and Propylene

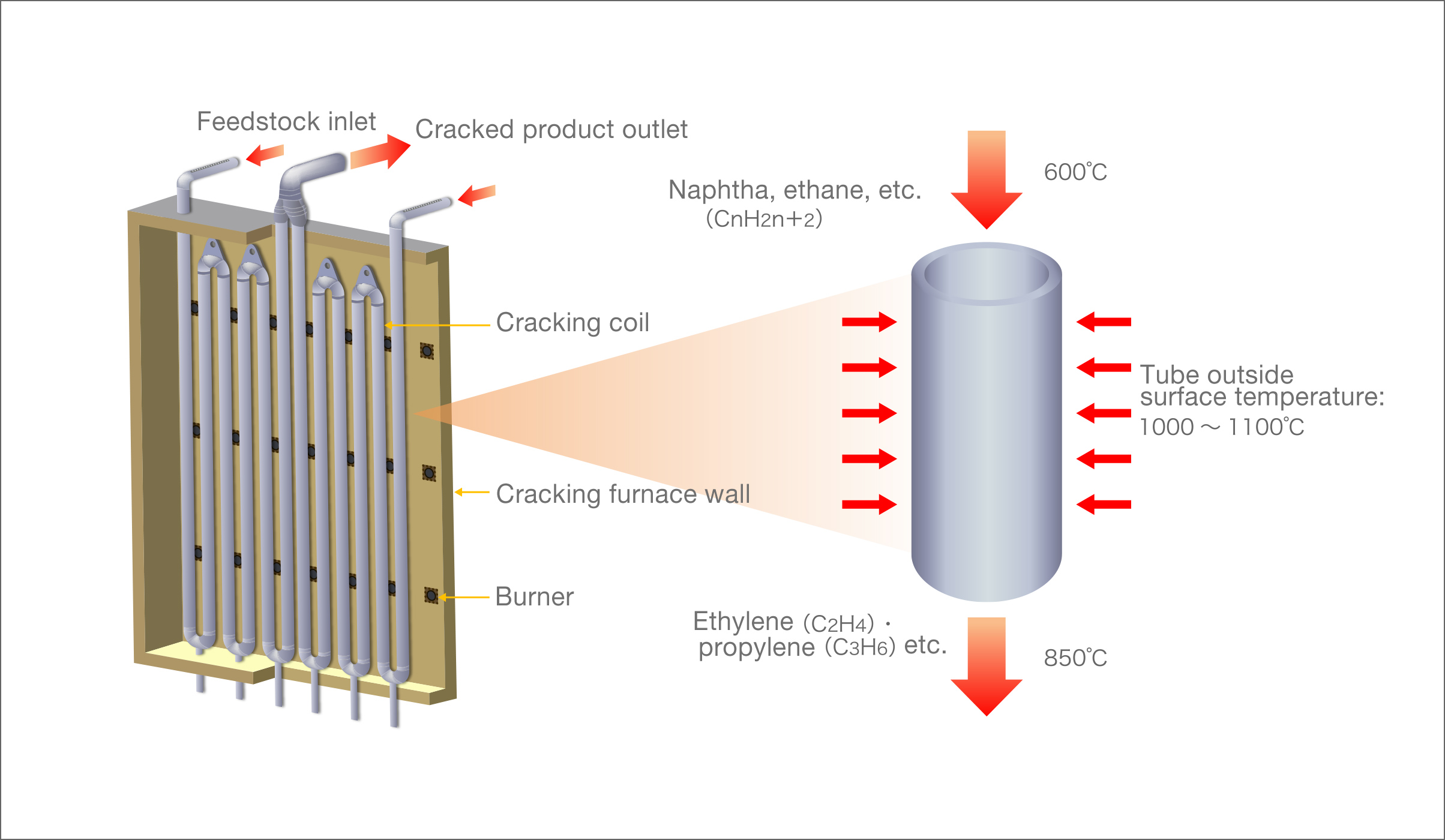

Petrochemical plants produce ethylene and propylene, which are the raw materials for plastics, through thermal cracking of hydrocarbons such as ethane and naphtha under high temperatures.

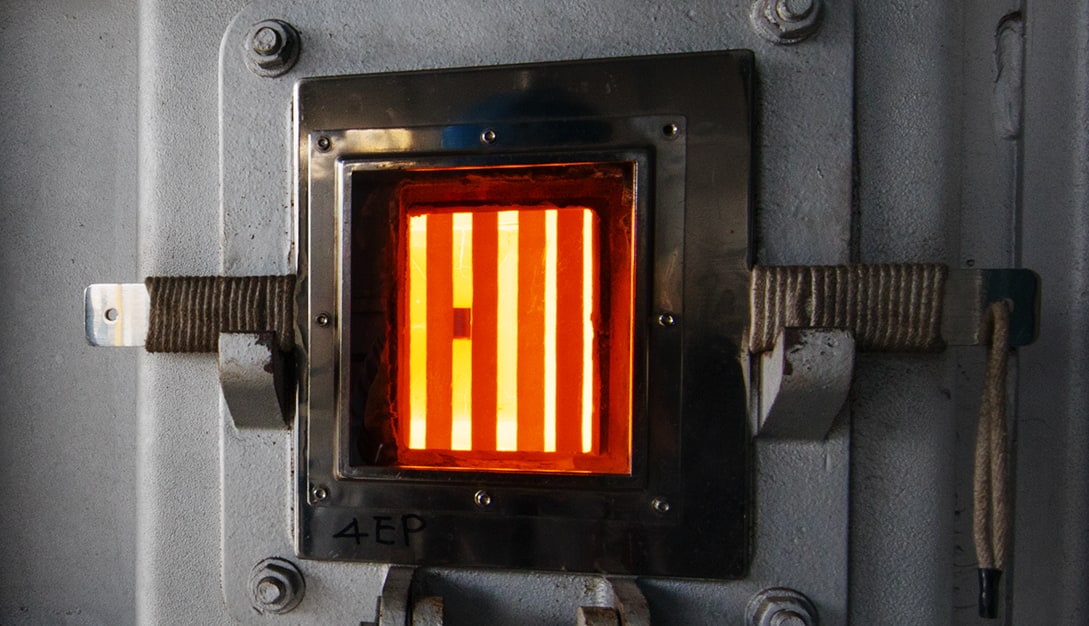

A cracking coil consists of cracking tubes and fittings. With the coil set in a thermal cracking furnace, hydrocarbon feedstock and steam are supplied and brought up to the cracking temperature range (800-900°C) with heat supplied from outside of the coil. In the process, cracking tubes are exposed to high temperatures of up to about 1100°C. Because they are used under such extreme conditions, cracking coils are required to have high heat resistance and thermal efficiency.

Thermal Cracking Furnace

New Technology for Higher Carburization Resistance and Thermal Efficiency

Coking (carbon deposition caused by free radical carbons) on the inside surface of a cracking coil, occurring as a result of thermal cracking of hydrocarbons, increases pressure drop in the cracking coil and lowers the heat transfer efficiency, eventually causing the reduction in the operation efficiency of a thermal cracking furnace.

Coking can also give rise to a phenomenon called "carburization" (where the base metal absorbs carbon) which shortens tube life.

Kubota developed high-performance cracking tubes based on our own unique concepts, as well as based on the experience and technological expertise in materials development and casting that we had gained through supplying key industrial steel casting products over many years. These tubes offer dramatically increased operation efficiency of thermal cracking furnaces while realizing superior anti-carburization performance.

We Deliver High-quality Cracking Tubes Worldwide, from North America, and Japan

- ◆Being the first to respond to market needs

- Our marketing bases in Ontario and Texsas, Japan are in close real-time communication. We propose products to meet user needs.

- ◆High-quality Kubota brand tubes made at global locations

- We have two production bases which all produce Kubota-brand cracking tubes of high reliability.

- ◆Delivery from the best production site

- Products are delivered from the best location for meeting the desired delivery date.

Global Network

History

1937 Manufacture of general steel castings commenced in Taisho-ku, Osaka City

1952 First centrifugal steel casting technology in Japan developed; industrial production of centrifugal cast steel pipes commenced

1990 Kubota Metal Corporation (now Kubota Materials Canada Corporation) founded in Ontario, Canada

Related Products

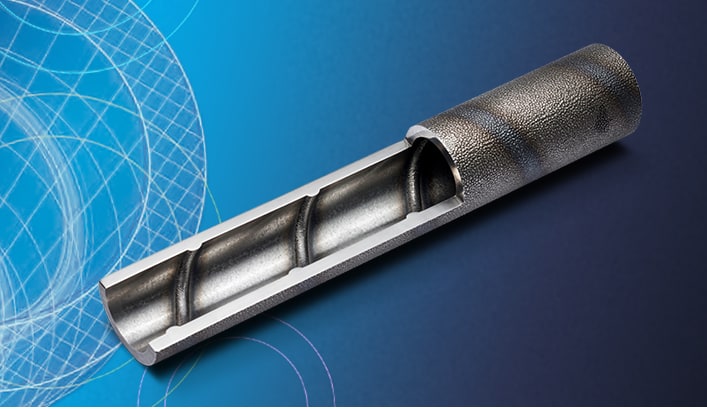

MERT

MERT is a high-performance cracking tube with "mixing elements" on the inside surface which increases heat transfer efficiency while realizing uniform temperature distribution of the fluids within.

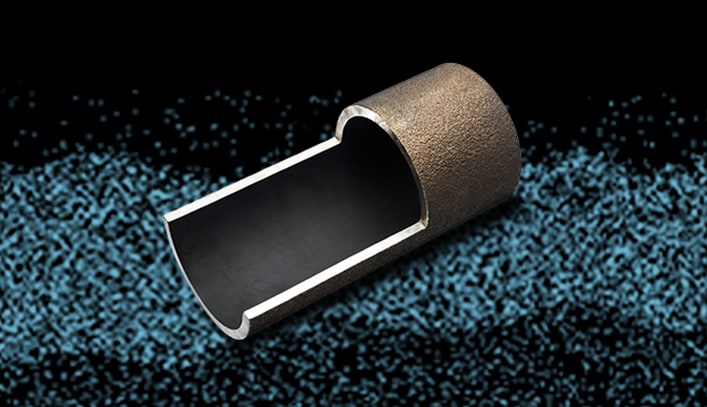

AFTALLOY

AFTALLOY is a next-generation, high-performance cracking tube with a robust inert aluminum oxide layer on the inside surface.

UCX

UCX is a cracking coil material with high anti-carburization and anti-oxidation performance in high temperatures in excess of 1100°C; it was developed by Kubota based on the company's technological expertise in heat-resistant steel alloy design gained through long experience.

Contact Us

To inquire about a product, service, maintenance, or any other matter, please contact your nearest Kubota location directly by phone or contact us by email. Before making an inquiry, we recommend that you check out our customer support information, including FAQs, as you might be able to find the answer to your question more quickly there.