Kubota Surface Melting Furnace Achieves >99.999% Destruction Efficiency of Perfluorononanoic acid (PFNA)

January 22, 2026

Kubota Corporation

Kubota Corporation (Head Office: Naniwa-ku, Osaka, Japan; President and Representative Director, CEO: Shingo Hanada; hereinafter “Kubota”) has succeeded in decomposing PFNA, a type of per- and polyfluoroalkyl substances (PFAS), with an efficiency over 99.999%—a requirement stipulated in the Technical Guidelines of the Basel Convention*1—as a result of a decomposition demonstration test using melting separation technology. This technology is currently utilized at multiple waste treatment facilities in Japan where Kubota has delivered equipment for the detoxification and resource recovery of hazardous waste, such as incinerator ash, and illegally dumped waste containing soil. In the future, if the decomposition capability can be confirmed for other PFAS in addition to PFNA, this technology is expected to enable the stable decomposition and resource recovery of waste containing PFAS, which would address a global environmental issue.

- *1 An international convention stipulating frameworks and procedures concerning the control of transboundary movements of specific hazardous wastes and their disposal.

1.Background

- PFAS have excellent water- and oil-repellency, thermal and chemical stability, and have been utilized in a wide range of applications, including surfactants, surface treatment agents, and firefighting foams. However, in recent years, specific types such as PFOS, PFOA, PFHxS*2, and PFNA have been designated as persistent organic pollutants (POPs) due to concerns regarding their environmental persistence and potential health effects, resulting in the expansion of strict international regulations*3. PFAS possess strong carbon-fluorine bonds and do not readily decompose in the natural environment. Consequently, one recommended method of decomposition is high-temperature incineration at 1,100°C or higher.

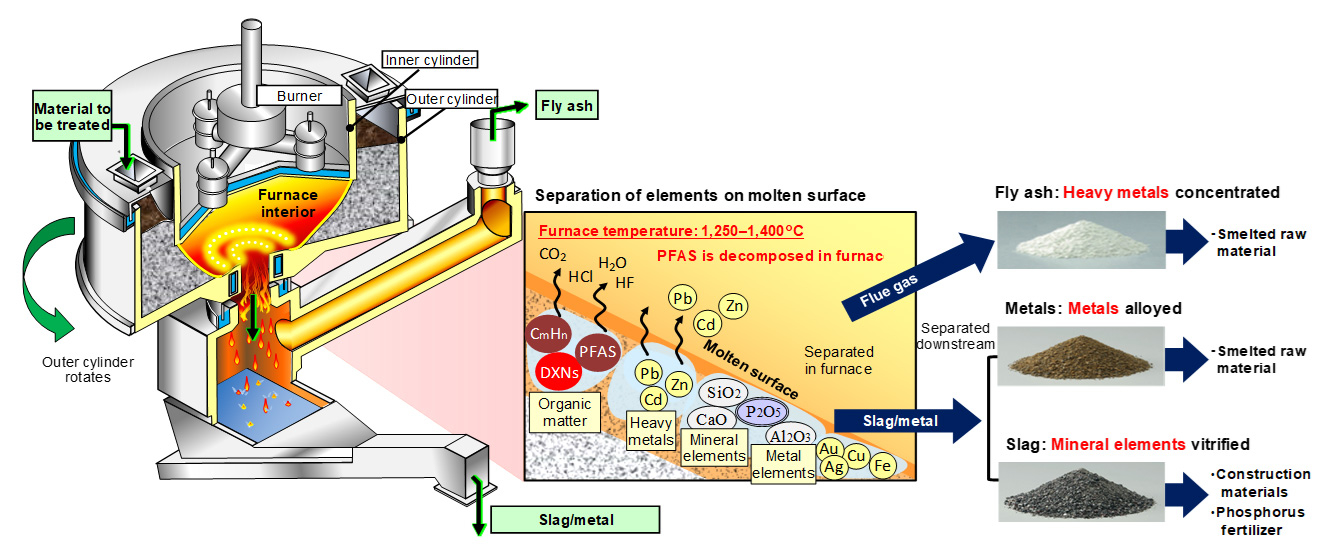

- To achieve appropriate waste treatment and resource recovery, Kubota develops and provides melting separation technology utilizing a surface melting furnace. This technology decomposes organic matter in incinerator ash or waste by high-temperature melting, while separating, concentrating, and recovering metals (including iron, copper, and precious metals), phosphorus (useful as a fertilizer), heavy metals, and other substances. During melting, the temperature inside the furnace reaches 1,250–1,400°C—a level capable of decomposing PFAS. To date, reports evaluating the decomposition capability of melting furnaces operating in this temperature range have been scarce.

- *2 PFOS: Perfluorooctane sulfonic acid, PFOA: perfluorooctanoic acid, PFHxS: perfluorohexane sulfonic acid.

- *3 Starting April 2026, compliance with standards and performing water quality tests related to PFOS and PFOA for tap water will become mandatory in Japan. In January 2023, The European Chemicals Agency (ECHA) submitted a comprehensive restriction proposal targeting approximately 10,000 types of PFAS, including fluoropolymers. In January 2025, the U.S. Environmental Protection Agency released the Draft Sewage Sludge Risk Assessment for PFOA and PFOS for public comment.

-

Mechanism for Decomposition of Hazardous Substances and Resource Recovery Using Melting Separation Technology

2.Details of the Test

- In the test, incineration ash spiked with a PFNA reagent and non-spiked incineration ash were fed into Kubota’s melting furnace, in separate experiments. The discharged slag, fly ash, and emitted flue gas were sampled. The concentration of PFNA in these samples was analyzed, and the hourly PFNA input and output amounts were calculated and compared.

- The incineration ash spiked with PFNA was fed into the furnace at a rate of 9,611.53 mg/h of PFNA, and the total PFNA output rate of the discharged slag, fly ash, and emitted flue gas after the process was less than 0.00649 mg/h. This was comparable to the total amount found in non-PFNA-spiked run, which was less than 0.00674 mg/h. This indicates that PFNA was almost entirely destructed by the melting process. Moreover, the calculated destruction efficiency*4 was over 99.99993%, confirming that it met the requirement stipulated in the Technical Guidelines of the Basel Convention (99.999%).

- This research has been jointly presented with the National Institute for Environmental Studies (NIES) at academic conferences, and received one of the Best Poster Awards at the International Water Association (IWA) Conference on Sludge Management.

- *4 Destruction efficiency = (PFNA input amount - Total amount of PFNA in slag, fly ash, and flue gas) ÷ PFNA input amount × 100 (Unit: %)

3.Future Outlook

- In addition to PFNA, Kubota will continue to evaluate the decomposition capabilities of the melting separation technology for PFOS, PFOA and other PFAS.