Kubota’s Vision for

Smart Agriculture Solutions

Smart Farming Can Solve Issues that Farmers Face and Ensure Sustainable Food Production

Food is indispensable for us to survive.

And we cannot do without the farms that produce this food and the farmers who operate those farms.

A sustainable approach to agriculture will be necessary to realize a society where people can dependably enjoy a safe and secure food supply. However, agriculture, both in Japan and around the world, faces a number of challenges, such as the aging of farmers, increasing sizes of farmland managed by professional farmers, the need to reduce labor and costs, rising environmental impact, and food loss and waste.

As one of the world’s leading manufacturers of agricultural machinery for both rice and dry-field farming, Kubota has been listening closely to farmers and developing farming products and solutions that meet their needs for many years.

By combining our legacy of technologies, products, and solutions with advanced technologies such as robotics and ICT, Kubota will help to solve the issues facing agriculture, to achieve sustainable agriculture with minimal burden on the Earth, and to contribute to sustainable food production.

Our Challenge

Issues Facing Agriculture Today

Farmers in Japan today face a broad range of challenges. These include managing numerous cultivated fields*1 scattered across multiple locations, improving yield and quality, reducing costs and labor burden, and adding greater value to the products they produce. Furthermore, the declining population of farm workers and the need to reduce environmental impact are issues that both Japan and the world must address.

- *1.Fields or farms on which crops are raised.

- The Various Challenges Faced by Agriculture in Japan

-

Japanese society is aging at an astounding rate. In 2023, the average age of farmers was about 68 years old*2. In the year 2000, there were 2.3 million farms engaged in sales in operation, but this number dropped to 1.3 million by 2015, and 1.02 million by 2020*3. This trend is expected to continue.

In accordance with these trends, the percentage of farmland owned by farmers and agricultural groups that have taken over land from farmers who left the profession or farmland that was not being used is increasing each year. For example, the share of total farmland held by professional farmers is increasing each year, reaching 58.9% in 2021*4.

- *2.Ministry of Agriculture, Forestry and Fisheries “Statistics on the Agricultural Labor Force”

- *3.Ministry of Agriculture, Forestry and Fisheries “Statistics on Management”

- *4.Ministry of Agriculture, Forestry and Fisheries “Trends in Accumulation and Concentration of Agricultural Land for Business Farmers”

- Food Demand Rises while Labor Shortages and Aging of Farmers Becomes More Serious

-

Looking at agriculture around the world, we see that other areas have concerns about aging and labor shortages like those in Japan. The global farming population was around 1 billion in 2000 but had shrunk to around 900 million by 2019*5.

As the shortage of labor and aging of farmers progresses, the global population continues to rise, and demand for food is expected to increase accordingly. Meanwhile, the proportion of individuals who cannot secure adequate nutrition is around 1 in 11 people*6. It will be necessary to provide sustainable agriculture and reduce food loss and waste in order for the world’s people to have sufficient and reliable access to food.

- *5.Food and Agriculture Organization (FAO) “Statistical Pocket Book”

- *6. Food and Agriculture Organization (FAO) “The State of Food Security and Nutrition in the World” (2023 edition)

- The Global Challenge of Reducing the Environmental Impact of Agriculture

-

We cannot ignore the impact of farming on the environment. Emissions of greenhouse gases (GHG) from agriculture, forestry, and other land use account for about 24% of total global emissions*7.

A variety of efforts are required to reduce the environmental impact of agriculture. These include controlling carbon dioxide and dinitrogen monoxide from cultivated soil, methane gas emissions from paddy field soil, and fuel oil consumption by agricultural machinery. Furthermore, a range of other initiatives are being called for, including reducing chemicals used for pest control and other purposes, limiting excessive application of chemical fertilizers that can lead to environmental pollution and GHG emissions, promoting organic farming, and decarbonizing agricultural machinery power sources.

- *7.National Agriculture and Food Research Organization “Development and dissemination of technologies to mitigate greenhouse gas emissions with enhanced agricultural productivity”

Our Approach

Problem-Solving Approach

Solving the various issues faced by farmers and achieving sustainable farming will require smart agriculture that utilizes robotics and ICT and enables ultra-labor-saving and high-quality production. Kubota is taking three approaches to advance the technologies and solutions it has built over the years.

What is Smart Agriculture?

Smart agriculture makes use of advanced technologies such as robotics, AI and IoT. Built on a platform that integrates various kinds of data required for smart agriculture, it automates work, simplifies information-sharing, and applies data to farm work. This will enable ultra-labor saving and make production of high value-added crops and advanced farm management possible for anyone.

Kubota’s Problem-Solving Approach

Our Strength

Advantages Kubota Demonstrates for Solving Agricultural Issues

Kubota has been grappling with agricultural challenges for many years. We aim to build an integrated smart agriculture system that can accommodate rice farming as well as dry-field farming, fruit trees, and other crops. This is the kind of smart agriculture system that Kubota can uniquely provide, and through this we will strive to solve various issues in agriculture and to realize sustainable and resilient food supply and better working conditions.

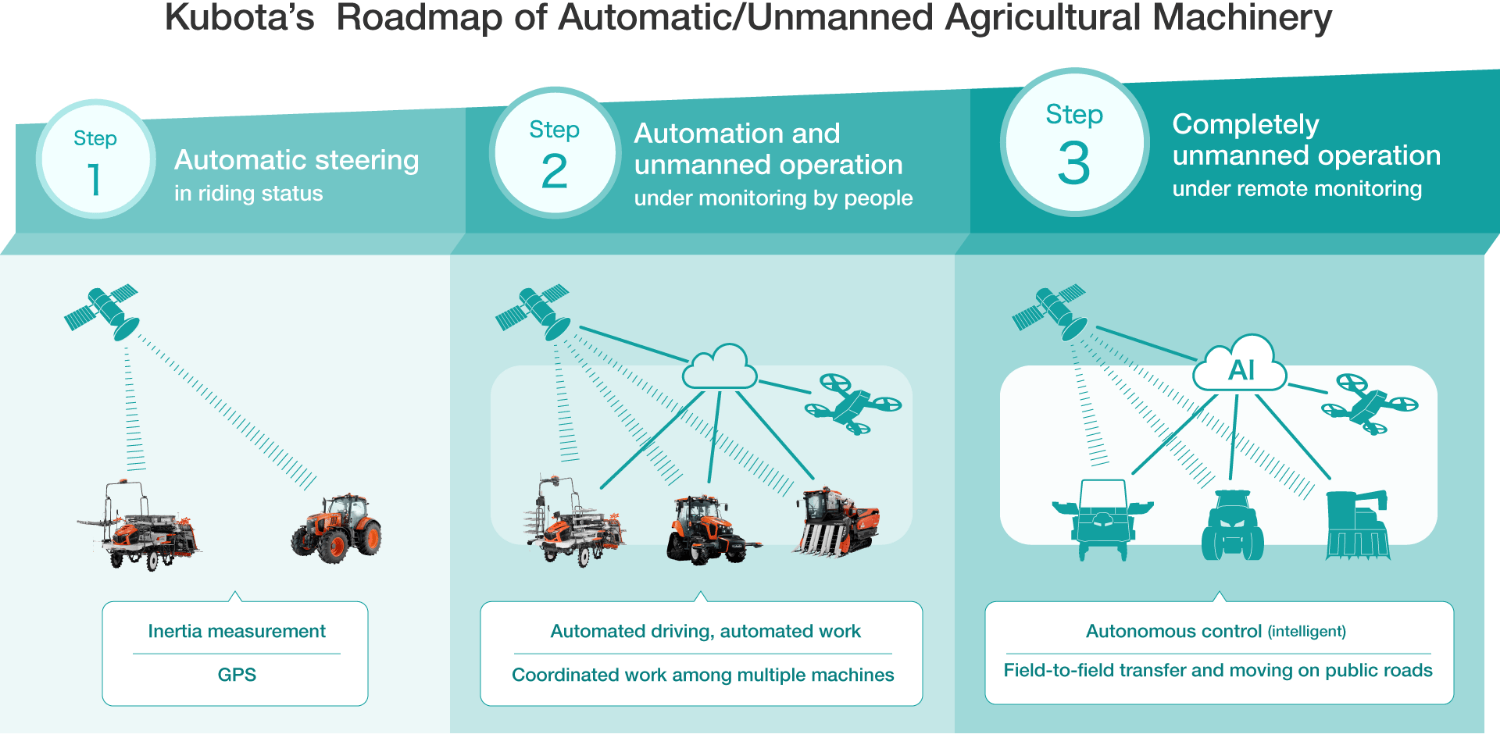

Ultra-labor Saving through Automated and Unmanned Machinery

Automated and unmanned machinery could be called an essential component for realizing ultra-labor saving in agriculture and efficiency in farm work. Kubota is pursuing research and development following the roadmap crafted by the Ministry of Agriculture, Forestry and Fisheries (MAFF), Japan for three levels of automation and unmanned operation of agricultural machinery.

Of the three steps outlined in this roadmap, Kubota has already released products for Step 2: “Automation and unmanned operation under monitoring by people.” In 2024, we introduced to the market the world’s first*8 combine harvester that could harvest rice and wheat with automatic operation without a person riding, completing our full lineup of tractors, combine harvesters, and rice transplanters capable of unmanned operation. And we are working on R&D in collaboration with public and academic research institutions for practical use of agricultural machinery capable of unmanned operation under remote monitoring with a target of 2026.

- *8.As of June 14, 2023; Kubota research.

Kubota’s efforts toward ultra-labor saving in agricultural work are not limited to rice farming. Through automated operation of large tractors for dry-field farming, automated harvesting systems for fruit trees using AI and robotics, and development of robots that can navigate rough terrain in mountainous areas, we are promoting labor-saving and efficiency in various areas of agriculture.

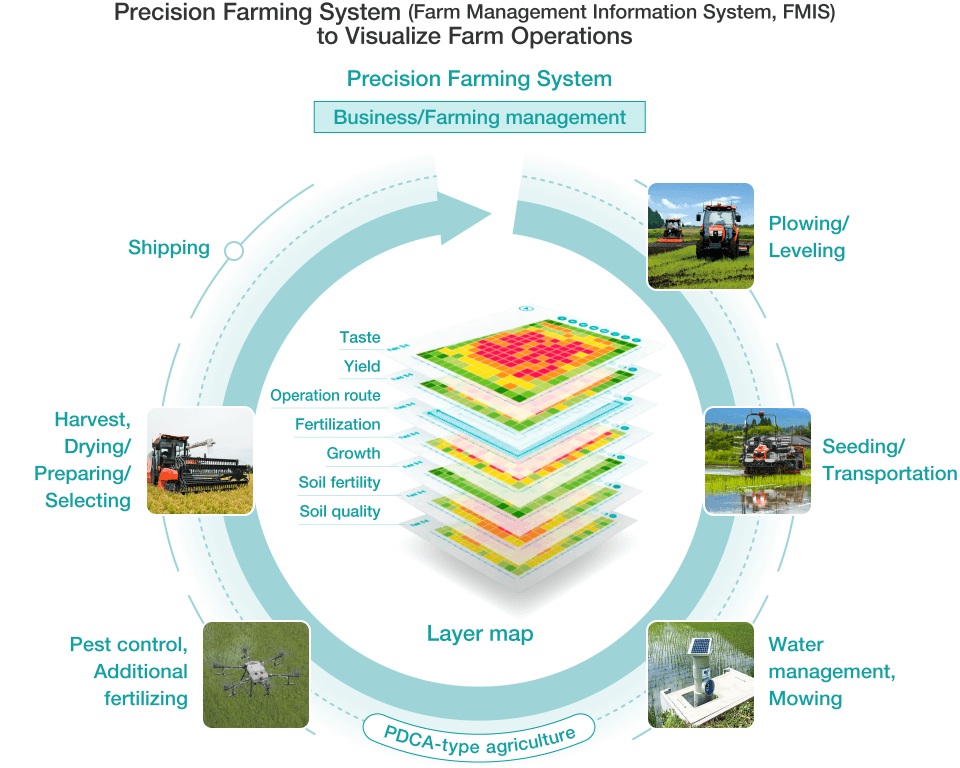

Achieving Precision Farming Based on Data

Kubota is working on a precision farming system (Farm Management Information System, FMIS) to visualize farm operations centered on data-based farming. This system brings together various kinds of data collected by ICT-equipped agricultural machinery and uses it to visualize crop information, improve work efficiency, optimize fertilizer application and water management, and improve crop quality.

To further advance data-driven agriculture, we are promoting the conversion of the precision farming system to an open platform so that it can be utilized in combination with external data when necessary. Agriculture is complex and affected by various environmental conditions, and through these kinds of initiatives, we are implementing precise management through data to enable agriculture that allows anyone to produce high-quality crops.

Agriculture without Burden on the Environment

Like many industries, agriculture faces the unavoidable social issue of addressing its environmental impact. Kubota is helping to realize carbon-neutral and eco-friendly farming through a variety of technologies and efforts, including reduction of GHG emissions from cultivated land and rice paddies, lowering the use of chemical pesticides and fertilizers, and utilizing cleaner fuels in machinery.

One example is how we contribute to lower GHG emissions from soil through technologies and product lines that improve efficiency of farm work through the use of automated machinery and GPS and help to promote direct seeding, rice straw ploughing, and no-till cultivation. We also reduce burden on the environment and on the soil by optimizing the amounts of fertilizer, chemical pesticides, and chemical fertilizers through our precision farming system. Reducing the use of pesticides and other chemicals also makes the soil more fertile, leading to production of better-quality crops.

From here onward, we will promote research and development aimed at decarbonization of power sources, including electrification and hybridization of machinery and fuel cells. In addition, we will promote the building of a circular economy in agriculture while incorporating solutions from different business arenas, such as the use of Kubota technologies that extract valuable resources (phosphorous) from waste material and biomass energy from straw.

Vision

Kubota’s Vision for the Future of Smart Agriculture Solutions

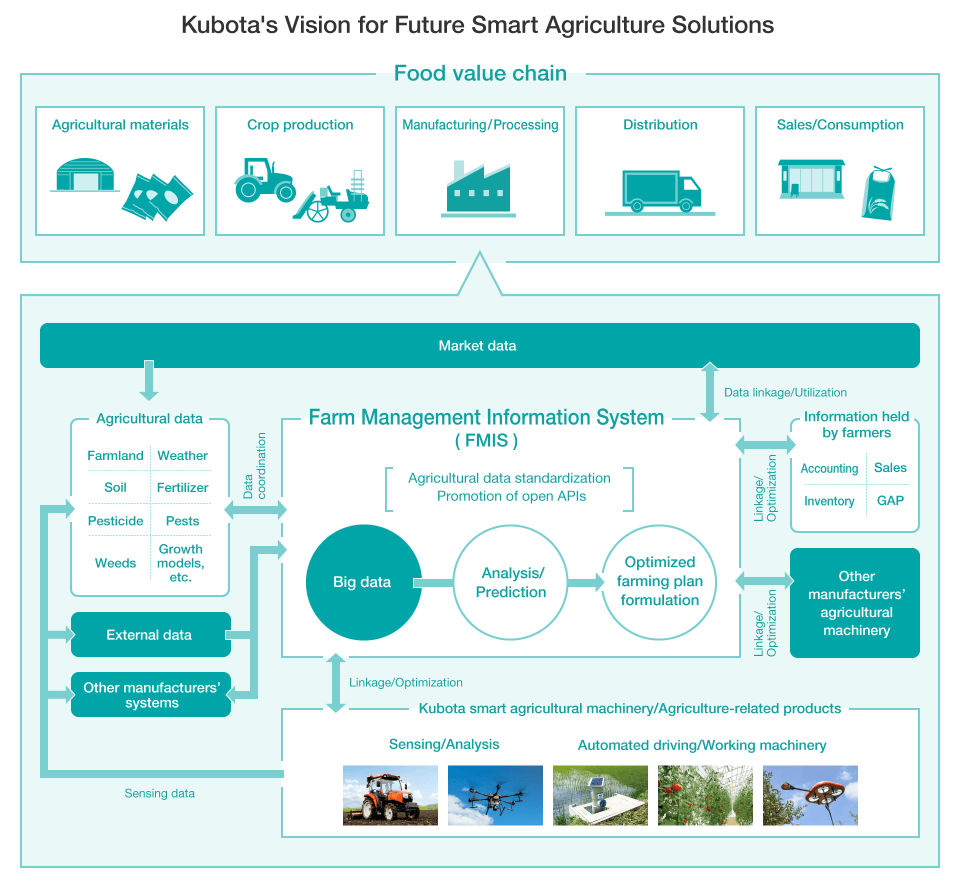

As the food sector faces various challenges today, including increasing food demand, decreasing farming populations, and the need for carbon neutrality, Kubota aims to contribute to the creation of sustainable food systems not only in crop production fields but also in the food value chain.

For example, our precision farming system could be used to analyze big data, which combines data from sensors on Kubota agricultural machinery and other manufacturers’ devices with external data from markets and other sources. The solution we envision could use this data to propose the right farming and business plans for the entire food value chain, ranging from production to consumption.

This will not only enable advanced PDCA-model agricultural management that dependably produces the required crops at required quantities, but will also contribute to reductions in food loss and waste.

From here onward, Kubota will continue to promote agriculture so that it becomes a more appealing industry through Smart Agriculture Solutions utilizing cutting-edge technologies, and we will contribute to eco-friendly and sustainable agriculture through means such as green energy-powered machinery and application of solutions from our water and environmental fields.

And not only for Japan’s agriculture but also in other regions such as Europe and Asia, we will provide solutions tailored to local needs, as we aim to contribute to the building of food systems that coexist with the global environment.

Smart Agriculture Solution Technology

Smart Agriculture Solutions enable sustainable agriculture and food production. Here we introduce Kubota’s technologies that shape methods of farming for each era and the advantages they provide. Kubota will continue to lead smart agriculture efforts using its technological integration capabilities.