Materials

Kubota supplies materials for different applications designed and manufactured using various molding methods, in addition to cast metal products, its original and core business. Originating from centrifugal casting technology, Kubota has vast lineup of value added materials such as constructional material and contributes to building the groundwork of social infrastructure.

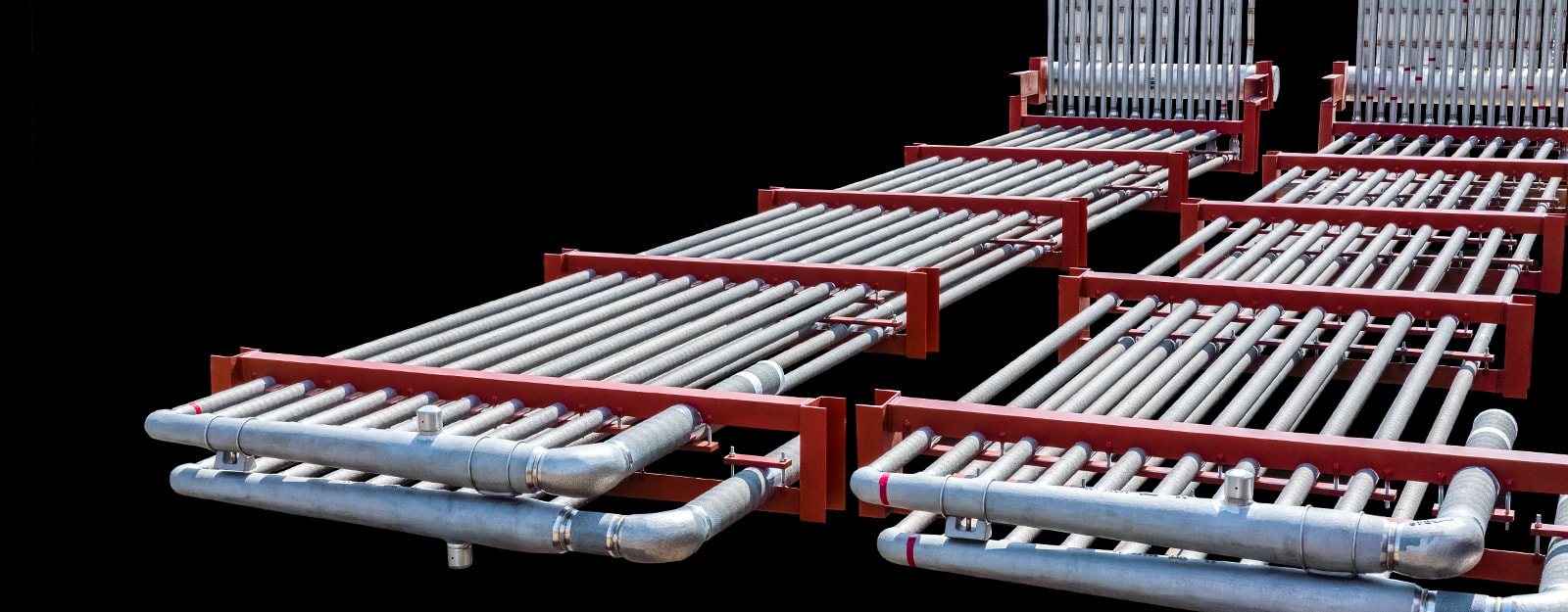

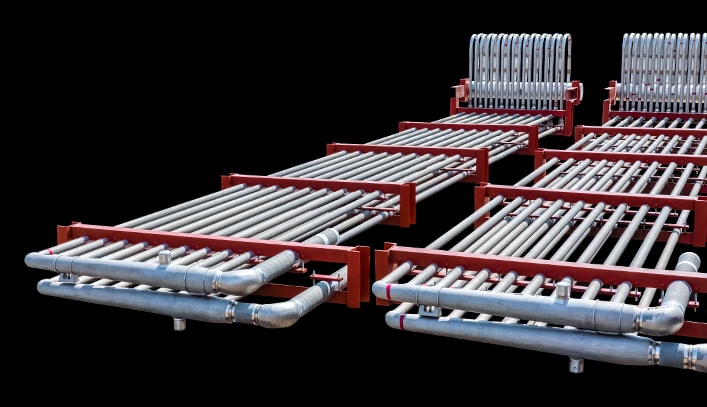

Kubota 's products include cracking coils for pyrolytic furnaces used in the production of ethylene, the primary material for manufacturing plastics, and reformer tubes for hydrogen production at oil refineries and ammonia (fertilizer) production plants. Currently, there is a growing demand for cracking coils, which are manufactured in Japan and Canada for distribution all over the world. Kubota contributes to society with a wide variety of products that ranges from steel-related products such as super heat-resistant alloys.

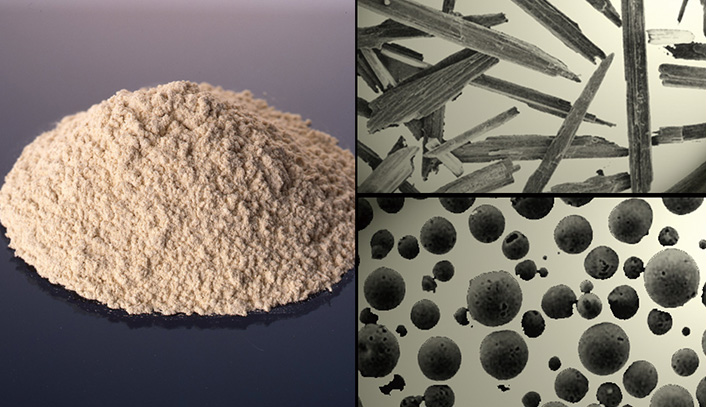

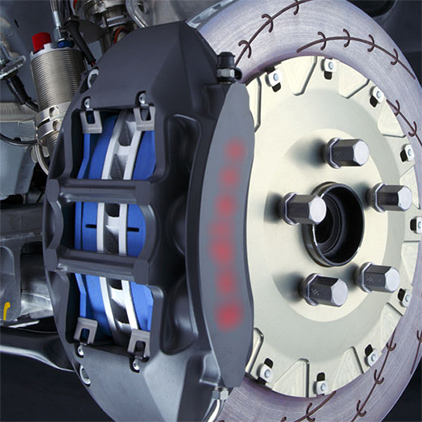

Furthermore, it has also put into practical use cutting-edge materials such as TXAX (potassium titanate fiber used as automobile brake pad material), ceramics and other composite materials.

Another key feature of Kubota's materials is that most of materials are manufactured based on our customers' requirements. Our long experience and expertise enable flexible adjustment to meet their needs. Kubota remains committed to developing materials of ever-higher added value that meet the diverse and increasingly complex needs of society.

- Product availability and specifications may vary by country or region. For more information, please contact the nearest Kubota from Global Network.

- For further information about this product in your local area:

-

Lineup

-

Cracking Coil

-

TXAX

Our Technologies

-

Centrifugal Casting

Centrifugal Casting Centrifugal Casting is the ideal process to make seamless pipes and cylindrical shape. By introducing molten metal into high speed spinning mold, sound metal will solidify in to cylindrical shape under high pressure due to centrifugal force.

-

MERT (Mixing Element Radiant Tube)

MERT is Kubota original new type cracking tube which has mixing effect by mixing element on the centrifugally cast tube inside. The mixing effect can achieve both good heat transfer and homogeneous heating of fluid in tube.

-

TXAX (Brake Pad Material)

This potassium titanate powder is most commonly used as a material for brake pads. It has superior frictional properties and resistance to abrasion and heat, as is required of an alternative to asbestos. Its safety as a material has been recognized in various countries and it has been put into practical use around the world, with demand for the product continuing to grow.

- For further information about this product in your local area:

-