First order for palm oil mill effluent treatment facilities in Indonesia — Kubota contributes to environmental improvement and the use of renewable energy development by its anaerobic membrane technology —

November 13, 2013

Kubota Corporation (Head Office: Naniwa-ku, Osaka; Chairman of the Board and President: Yasuo Masumoto; hereinafter referred to as "the Company") has received an order for 5 plants to recover biogas from Palm Oil Mill Effluent (POME) in Sumatra in the Republic of Indonesia, in a joint venture with a local construction company. This is the second order received in the region, following the first order in Sarawak, Malaysia in October last year. It is the first order received in Indonesia.

1. Overview of the Contract

| Contract date | August, 2013 |

|---|---|

| End user | Asian Agri Group* (Individual contracts with 4 palm oil mills under this Group) |

| System | Kubota Anaerobic Membrane Bioreactor System

|

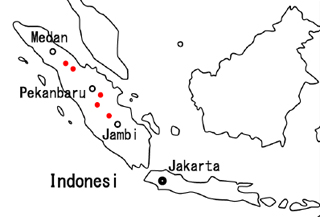

| Plant site | Sumatra, Republic of Indonesia - Total of 5 plants

|

| POME processing capacity | 420 m3 / day (per plant) |

| Electric power generation | 1.2 MW x 5 locations: Total 6 MW |

| Start of operations | Planed from April 2014 onwards |

| Scope of work | The Company is responsible for plant design, equipment procurement and construction supervision |

- Asian Agri Group:

A major palm oil business group in Indonesia. It owns 160,000 Ha of plantation and oil mills in 19 locations.

2. Background

- Palm oil is a major export product for Indonesia and Malaysia. POME is usually processed in reservoirs (open lagoons) and it is causing water and air pollution, leading to global warming.

- In recent years, increasing demands for environmental conservation from the consumers of palm oil have prompted the palm oil mills to start implementing environmental protection measures. By adopting Kubota Anaerobic Membrane Bioreactor System, Asian Agri Group intends not only to implement environmental measures, but also to use the recovered gas to increase the amount of electricity it generates and expand its production.

3. Advantage of Kubota Anaerobic Membrane Bioreactor System

- The system has dramatically increased biogas yield through its thermophilic and high concentration operation. (20% or more higher than other systems)

- By enhancing the anaerobic membrane tank (by adding more membranes), an increased amount of POME (resulting from increased palm oil production) can be treated with the existing digestion tank. It is therefore possible to reduce the expenditure of equipment investment. By this enhancement, each system can process up to 800 m3 per day.

4. Future developments

- Asian Agri Group is a major palm oil manufacturer in Indonesia and the Company will leverage this Contract to expand sales activities to other mills owned by the Group. Furthermore, the Company also plans to actively carry out sales activities targeting the other 600 palm oil mills throughout Indonesia

- The Company is determined to tackle food, water and environment problems around the world. By promoting Kubota Anaerobic Membrane Bioreactor System, the Company hopes to make a contribution to environmental conservation and the promotion of renewable energy use, at palm oil mills in Indonesia and Malaysia, which produce 85% of the palm oil consumed globally.

<For reference>

-

Locations of Asian Agri plant sites

●= plant site -

First plant in Malaysia (For BBC Biogas Sdn.Bhd)

Complete view of Kubota Anaerobic Bioreactor System