Published in Financial Times

August 28, 2019

Kubota boosts rice farming in rising Africa

Kubota, the global leader of rice farming equipment, sees the challenge of lifting agricultural yields in Africa as a tremendous opportunity. The mechanization of rice production will not only enable the continent to feed itself sustainably, but also liberate human capital and accelerate development.

Africa is rising, so must its rice production

Africa is flourishing. In recent years, the continent has enjoyed welcome political stability, steady growth, a boom in foreign investment, burgeoning cities, and a jump in life-expectancy.

But as home to the world’s fastest growing population, with the Sub-Saharan region alone expected to gain an additional one billion people by 2050, one key challenge remains: how will Africa sustainably feed itself?

As standards of living rise, more Africans are eating more. In particular, demand for rice, not traditionally eaten in the continent apart from areas of Western Africa, has soared. Urban-dwellers with rising incomes are switching from other staples to the more “premium”, but also easier to prepare and store, rice. The cereal is expected to replace maize as the main source of calories for the continent in two decades.

To meet demand, Africa imported over 14 million tonnes, worth 6 billion USD, last year. Relying ever more on imports is a risk as yield improvements for major Asian exporters have plateaued and global supplies tighten.

The good news is that Africa has vast untapped potential. According to the World Bank, the Sub-Saharan region has 200 million hectares of suitable land not used for crops, almost half of the world’s total. Rice yields in the region are now only a little over 2 tonnes for every hectare, less than half of that achieved in Asia. Much of that productivity gap stems from low levels of irrigation and mechanization.

Half a century ago, Kubota, the Japanese rice farming equipment manufacturer, played a pioneering role in lifting rice yields in Asia. It hopes to do the same for Africa. This will help the continent be able to better feed itself, and also become a net exporter of food for the rest of the planet.

“We see the African market as a tremendous opportunity,” says Masatoshi Kimata, President and Representative Director of Kubota. “Our company is committed to supporting rice farming on the continent.”

The Osaka-based company is not only the world’s leading supplier of farming equipment and water infrastructure, but also a leading maker of engines, small construction equipment, and utility vehicles. For the year ended in December 2018, the company marked record revenue of 1,850.3 billion yen (16.8 billion USD) and operating profit of 189.3 billion yen, with 68.8 per cent of sales generated overseas. (IFRS, Year-end TTB USD=110 yen)

From Asia to Africa

Like Africa today, rice yields in Japan and the rest of Asia were stagnant until the advent of mass mechanization. Kubota began mass-producing tractors, transplanters, and combine harvesters for rice farming from the 1950s, transforming Japanese agriculture and society. The labour-saving machines enabled human capital from farming households to move to cities and fuelled the country’s post-war economic boom.

The Japanese company soon began exporting these machines to its Asian neighbours and, since the 1970s, began manufacturing them overseas too. Now it is the top global supplier of machines used for rice. Its brand ubiquity is such that in several countries in Asia and Africa, “kubota” has become a synonym for cultivators and tractors.

The absolute volume of Kubota equipment sales in Africa remains limited, at about several hundred units per year. But as local farmers gain exposure to Kubota’s products, including through second-hand equipment, they are discovering its remarkable durability. Better fuel efficiency of Kubota engines has also been a draw. Reliability and lower fuel costs are critical for the bottom line of local farmers and contract drivers.

“To supply tractors in a wide range of prices, including affordable ones to farmers in emerging markets, we entered a joint venture with Indian tractor manufacturer Escorts Limited last year,” explains President Kimata. “We will first target customers in India, and then export to the rest of the world, including Africa.”

Investing 3 billion rupees (42.1 million USD) for new production facilities in India, the joint venture will have a capacity of producing 50,000 tractors per year from 2021.

Kubota is also building up a service and maintenance network, rare in the continent. Centres of distribution have been developed with local partners in Tanzania, South Africa, and Côte d'Ivoire, with further expansion plans elsewhere in Western Africa.

Tanzania is growing tonnes

One of the success stories of rice production in Africa is Tanzania. It is one of three countries in the continent, along with Mali and Madagascar, with nearly complete self-sufficiency in rice. Since the 1970s, the Japanese government and companies like Kubota have backed Tanzanian rice farming through irrigation projects, mechanization, and training programs. With recent assistance provided through CARD (see column), the country’s rice production has doubled over the past decade.

Yet mechanization remains incomplete. The number of tractors per 100 square kilometres of arable land in Tanzania is a tenth of the average levels of Asia and a hundredth of those in Japan, which have the highest levels in the world. Done manually, it takes 10 farmhands one week to harvest one hectare of rice. A Kubota combine harvester completes the same task in an hour. Labour-intensive farming means that nearly 70 per cent of Tanzania’s workforce is tied to agriculture. With more machines working the fields, children will be able to stay in education while adults can engage in other industries and services, boosting overall development.

As global trends go, such mechanization will also inevitably be accompanied by “smart farming” solutions, particularly those that can mitigate the challenges of climate change.

And where precision farming for rice is concerned, Kubota is the top-runner. In 2014, the company launched KSAS (Kubota Smart Agri System), a cloud-based agricultural management service integrating and visualizing data collected from farm equipment. Already more than 6,000 farms in Japan are using this ICT system to achieve higher quality rice harvests. By adopting these cutting-edge technologies Tanzania and other countries in the region will be able to raise yields from rice even further in the future.

Not just rice

Africa needs solutions not just for agriculture, but also for its booming cities. Both require sustainable water systems: one for the irrigation of farmland and the other for sanitation and delivering drinkable water to densely populated areas.

In both areas, Kubota has been a path-breaker. Originally a steel foundry, the company has supplied water pipes and water purification systems for cities in Japan and the world for more than a century. In the 1970s, Kubota provided pipes and pumps to “green” a portion of the Sahara Desert in Egypt. Since then, it has delivered piping to more than a dozen countries on the continent. Africa’s growing cities are likely to generate greater demand for the kinds of purification systems to treat and recycle wastewater offered by the company.

For Earth, For Life

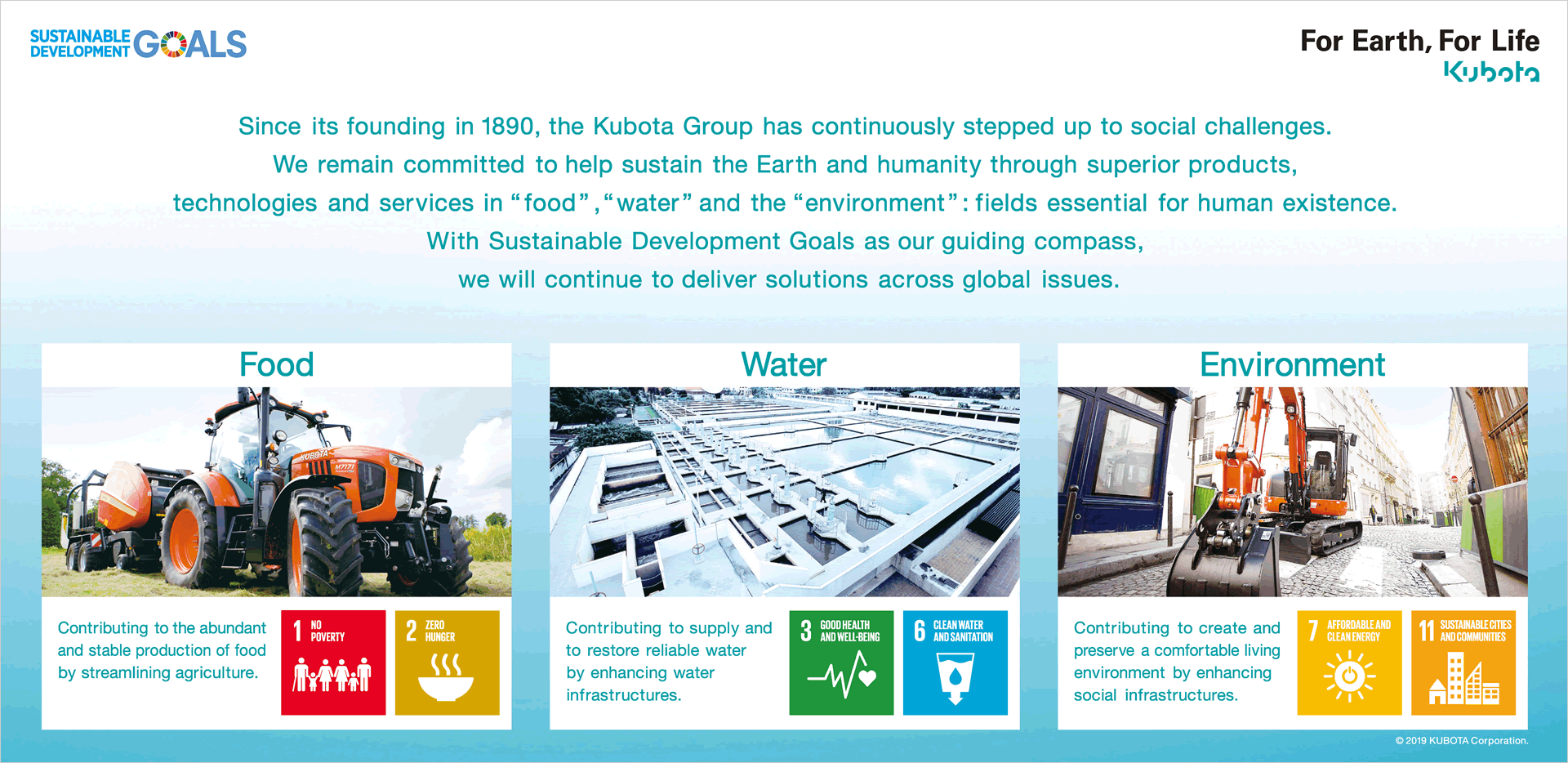

Across the globe, Kubota’s disparate solutions are all working, as its company brand statement claims, “For Earth, For Life”.

“Since its founding, Kubota has evolved its technologies to contribute in the areas of food, water and the environment, which are indispensable to the development of humankind,” says President Kimata.

“Africa is no exception. As the continent rises, we hope to work hand in hand and on-the-ground as partners in its development.”