Expansion of Production Capacity of Cracking Tubes for Petrochemical Plants:

Tackling high demand and production of hydrogen to achieve carbon neutrality with the expansion of a production line at Hirakata Plant

September 5, 2023

Kubota Corporation (Head Office: Naniwa-ku, Osaka, Japan; President and Representative Director: Yuichi Kitao; hereinafter “Kubota”) will expand the production capacity of cracking tubes*1 for petrochemical plants. Kubota will add a new production line to its main plant at Hirakata, Osaka and increase the annual production capacity to approximately 180%. This increase of capacity will allow Kubota to address the growing demand associated with the new petrochemical plants construction and the tubes replacements in existing furnaces as well as the hydrogen production which is attracting attentions as a new carbon neutral energy source.

- *1.Tubes made of heat-resistant cast steel used in petrochemical plants to produce ethylene and propylene through thermal cracking of hydrocarbons such as ethane and naphtha under high temperatures.

1. Background and Objectives

- Kubota manufactures and sells cracking tubes used in petrochemical plants to produce ethylene and propylene, which are raw materials for synthetic resins, and it has the biggest share in the world.*2 Kubota is particularly strong in high-performance products that achieve high productivity by adding helical ribs inside the surfaces of tubes and also forming a special layer on the inner surfaces to extend the tube life.

- *2.According to a survey we conducted

- In the future, high demand for cracking tubes is expected on the grounds of increased construction of new petrochemical plants in Asia as well as planned facility upgrades in North America. In addition, with the demand for carbon neutrality, there is a growing need for highly functional cracking tubes with features such as high productivity and extended tube life that can efficiently produce ethylene, propylene, and other products.

- Furthermore, there is the possibility of utilizing the development expertise and manufacturing technology of cracking tubes with excellent heat resistance in the mass production of hydrogen through thermal decomposition of ammonia, for example. The market is also expected to expand toward producing hydrogen for carbon neutrality.

- Kubota will increase the annual production capacity of Hirakata Plant, which is the main plant for cracking tubes, to about 180% of its current capacity by adding a production line to meet the demand expected in both existing and potential new markets.

2. Expansion of Production Line

- Commencement: April 2026 (planned initiation for all facilities)

- Sequential production scaling will commence upon the completion of individual facility installations.

- Investment: Approx. JPY 4.45 billion

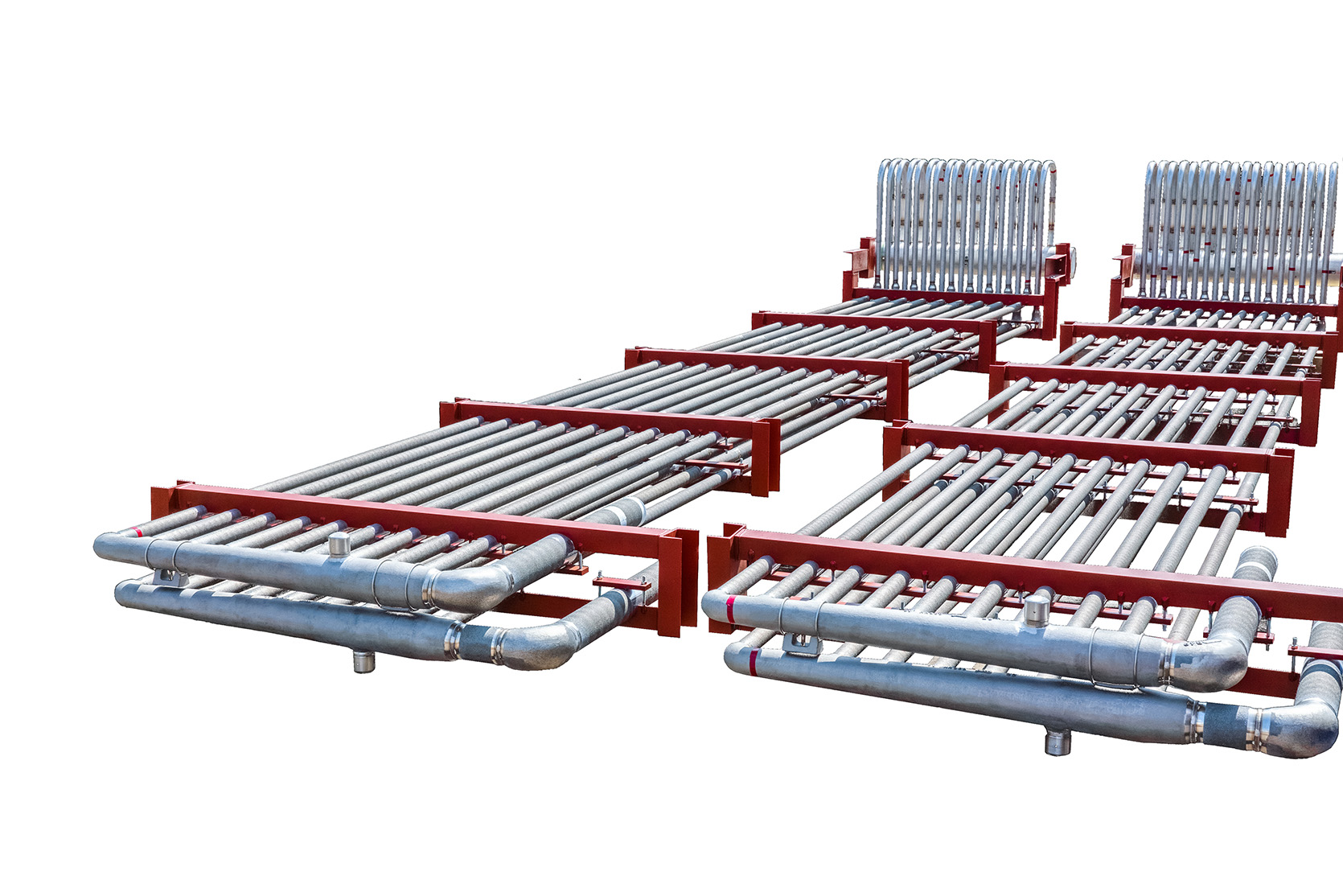

3. About Cracking Tubes

Cracking tubes are used in equipment that heat ethane and naphtha at high temperatures in petrochemical plants and pyrolyzes them to extract ethylene (pyrolysis furnaces). In Hirakata, we also manufacture reformer tubes used in petroleum refining plants and other equipment that reform natural gas at high temperatures and pressures to extract hydrogen for industrial use (steam reformer furnaces).

4. Hirakata Plant Overview

| Address | 1-1-1 Nakamiya-Oike, Hirakata-shi, Osaka, 573-8573, Japan |

|---|---|

| Production items | Cast steel products (including cracking tubes), construction machinery, pumps, and valves |

Reference

“Research and Development of Large-Scale External Thermal Ammonia Decomposition Hydrogen Production Technology” selected under the New Energy and Industrial Technology Development Organization’s (NEDO) project for the “Development of Technologies for Building a Competitive Hydrogen Supply Chain”