KUBOTA TECHNICAL REPORT No.53 JANUARY 2020

Kubota’s Legacy Creed

In this issue, No. 53 of the Kubota Technical Report, readers will find examples of products and services that serve the public in accordance with our founder's creed. It includes articles about the development of products such as tractors, combine harvesters and rice transplanters with automated driving assist functions that contribute to greater efficiency and reduced workloads in farm operations, and to improved productivity through application of ICT; air purifiers to help prevent infectious diseases by sterilizing and humidifying indoor air; earthquake-resistant ductile iron pipes and plastic flanges that contribute to the development of robust water supply and sewerage infrastructures; and new services that utilize cloud computing and AI. We hope that you will read this report and thereby gain a deeper understanding of Kubota’s activities.

Farm & Industrial Machinery

Development of Tractor for Domestic Market with a “Keeping Straight Function”Compact Tractor Engineering Dept.

In Japanese agriculture, against the background of an aging population, the proportion of inexperienced workers is increasing and the consequent shortage of skilled human resources is becoming a serious problem. As one of the solutions to this problem, in 2016, Kubota released onto the market a rice transplanter with a “Keeping Straight Function” for use in rice paddy cultivation. Similarly, field cultivation with a compact tractor requiring skilled and experienced operators has the same problem. To address this problem, Kubota has developed a compact tractor with “Keeping Straight Function” to save labor and improve efficiency (Fig.1). This paper describes the efforts made in the development process and definesthe characteristics of working with a compact tractor.

- Robot

- Automatic Steering

- GNSS

- GPS(Global Positioning System)

- Sloping Groun

- 【Related SDGs】

-

Development of Autonomous Driving Assist Combine Harvester WRH1200ACombine Harvester Engineering Dept.

Japanese agriculture is accelerating the consolidation and expansion of farmland to principal farmers due to the decrease in the number of farmers as a consequence of those abandoning farming and aging. However, principal farmers are confronted with various problems such as labor shortages and the need to reduce labor costs. In order to solve these problems, Kubota has commercialized rice transplanters with a straightahead function and autonomous driving tractors using the Global Navigation Satellite System (GNSS). Even in the combine, at the time of harvesting, it was still necessary to reduce the burden on the workers who had to work continuously from harvesting → drying and winnowing → shipping and faced long hard days as a consequence. In response to these demands, we have also launched WRH1200A, an autonomous driving assist combine harvester that uses GNSS, and is based on the concept of "a combine harvester that makes it possible anyone to perform optimal harvesting easily and without waste".

- Combine Harvester

- Autonomous Driving

- GNSS

- Driving Control

- Assist

- 【Related SDGs】

-

Development of Diesel Rice Transplanter NW6S/8S for Domestic MarketTransplanter Engineering Dept.

In domestic agriculture, there is an ongoing process whereby farmland is being consolidated and taken over by large-scale farmers, and it is important to develop products that meet the needs of these leading farmers. Based on the concept of creating a "high-performance and high-precision rice transplanter that solves the management issues faced by farmers in charge", we have developed a product that features two major selling points: improvement in basic performance and reducing the consumption of materials. This paper describes, among the development technologies, efforts to improve Fukada's running ability, which is one of the basic requirements of a rice transplanter, and the development of the functions to “Maintain an even distance between rows” and “Maintain even fertilizer application” have been created as new selling points that lead to material savings.

- Ability to Run in Deep Rice Fields

- Weight Saving

- Material Saving

- High Accuracy

- Slip Compensation

- Hydrostatic Transmission

- 【Related SDGs】

-

Development of RTV-XG850 Hi-speed Petrol-powered ModelUtility Vehicle Engineering Dept.

The market volume in North America for utility vehicles has doubled from about 240 000 units in 2010 to about 490 000 units in 2018. The utility vehicle market is dominated by high-speed petrol-powered vehicles that are used not only on work sites but also for leisure activities. To expand its business, a decision was made for Kubota to enter the high-speed utility vehicle market. Therefore, in 2018, we released the RTV-XG850 into the high-speed petrol-powered utility vehicle market. This paper describes the following three technical development features of the RTV-XG850. 1) Emission certification with the vehicle (CARB/EPA, FTP-75(b) MODE) that was first trialled for KBT. 2) Electric power steering system for safer handl ing and good maneuverability. 3) Disk brake system with a strong braking force and high durability.

- Utility Vehicle

- High-speed Petrol-powered Market

- Electric Power Steering System

- Disk Brake System

- Emission Certification with the Vehicle

- CARB/EPA FTP 75(b)MODE

- 【Related SDGs】

-

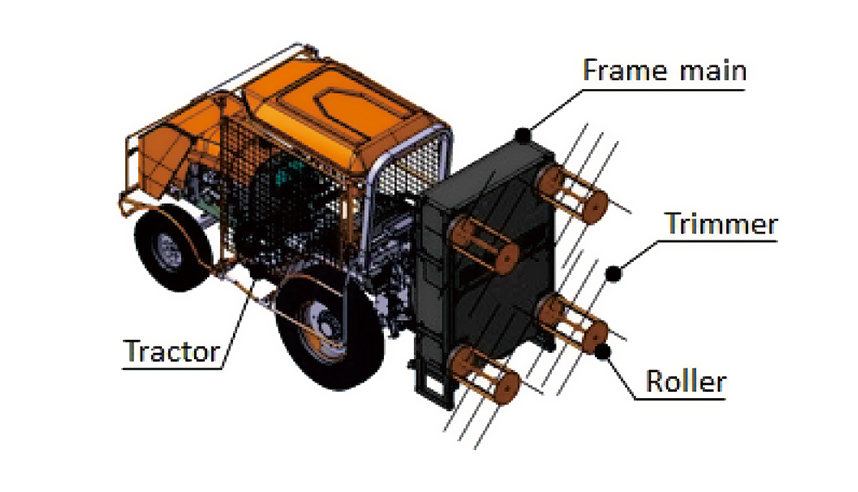

Development of Sugarcane Leaf Remover SLR110HKUBOTA Research & Development Asia Co.,Ltd.

Sugarcane is one of the major crops in Asian countries. The sugarcane harvesters currently being used in the agricultural sector are imported from Europe; however, they are not popular because of high yield loss and a high degree of leaf contamination. Moreover, these machines are also expensive. Therefore, most harvesting (around 83%) is still done by hand and before harvesting the sugarcane leaves are removed by burning. But burning not only affects the farmer’s income from yield loss and reductions in the selling price, but it also causes the problem of air pollution (PM2.5). This has become such a serious problem in Thailand that the government has announced a “zero burn" policy to combat pollution. Therefore, Kubota Research and Development Asia (KRDA) has developed SLR110H to support the “zero burn” policy and help save the environment. Now, the sales volume of SLR110H is increasing steadily and we expect to export to every country throughout Asia.

- Sugarcane Leaf Remover

- Roller

- Trimmer

- 【Related SDGs】

-

Development of High Capacity Pneumatic Seed Delivery SystemGreat Plains Manufacturing, GP Engineering

The mechanization of global agriculture has increased competition in the marketplace, and as a result more efficient and productive technologies are needed. Higher planting speeds improve efficiency but require more capacity from pneumatic seed delivery systems. Planting while the planter is turning using conventional drive technologies causes incorrect plant spacing as the outside rows of the planter travel a larger distance than the inside rows. The Great Plains PL5000 series of planters incorporate numerous developments that improve user efficiency and yields. The pneumatic seed delivery system was designed to increase the maximum planting speeds and crop types that it will support. The seed meter drive controller provides turn compensation with automatic adjustments across the planter width to maintain correct plant spacing whether near the center or outside of the turning radius.

- Pneumatic Seed Delivery

- Turn Compensation

- Planter

- Precision Drill

- Computational Fluid Dynamics

- 【Related SDGs】

-

Development of CRS-ECUEngine Engineering Dept.

Recently, industrial diesel engines are required not only to deliver lower fuel consumption, but also to meet emission regulations and a range of customer demands. CRS-ECUs have become a more important factor to increase the value of the engine itself because applying advanced electronic control techniques with CRS has almost become indispensable for meeting these requirements. However, conventional development of CRS-ECUs is too costly because there are some issues with their hardware and software architectures. Hence, we have to establish a more efficient process to maintain our market competitiveness. In order to resolve these problems, we developed new CRS-ECUs.

- ECU

- Common Rail System

- Model-based Development

- AUTOSAR

- 【Related SDGs】

-

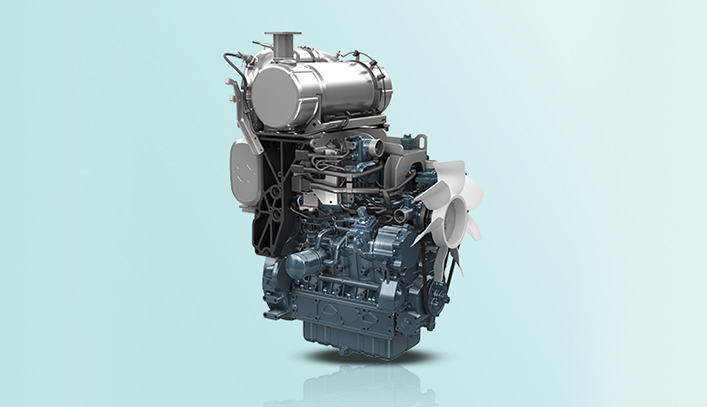

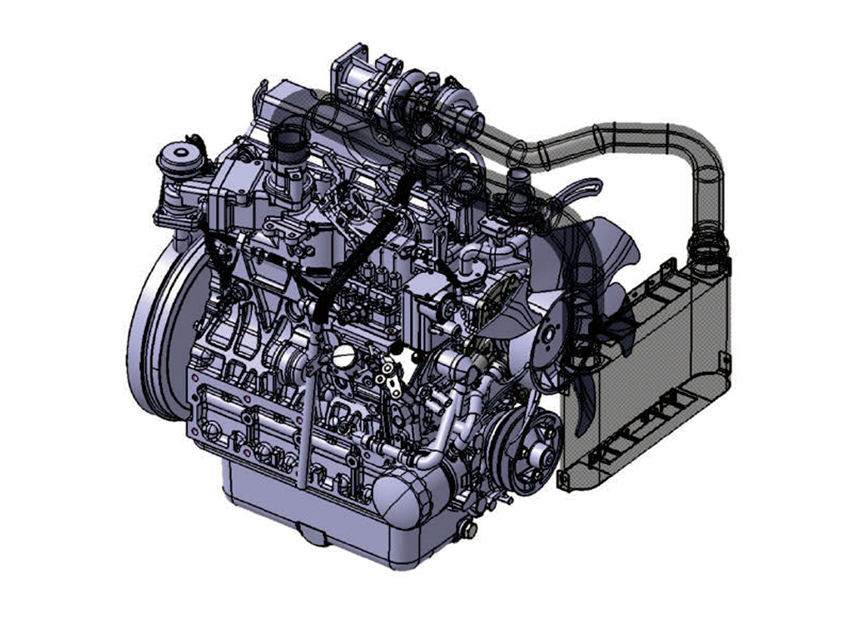

Development of V2403-M-DI-TI Diesel Engine (KET) for PRO758 General Purpose Combine Harvester for Chinese MarketEngine Engineering Dept.

The V2403-M-DI-T (68PS) diesel engine installed in a KAMS (Kubota Agricultural Machinery SUZHOU) main combine harvester PRO688 has been mass-produced by KET (Kubota Engine Thailand) since 2015. This is the first 4-valve 03 series engine E-CDIS (Environment, Earth, Ecology-Center Direct Injection System) system, and it meets the need for low fuel consumption. In order to meet the market requirements for even lower fuel consumption and higher output, we developed the intercooled turbo engine V2403-M-DI-TI(75PS) installed in a KAMS new model combine harvester PRO758. In this paper, we describe the approach we adopted to improve reliability, which is the most important task when attempting to achieve high output and low fuel consumption.

- KET

- V2403-M-DI-TI

- Low Fuel Consumption

- Higher Output

- High Durability

- 【Related SDGs】

-

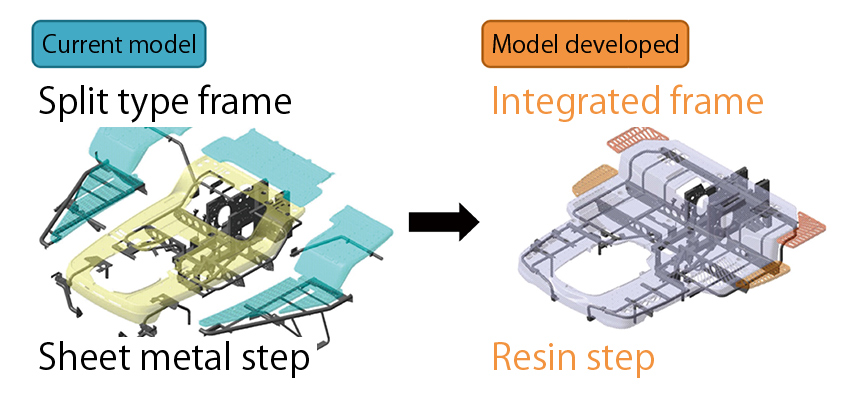

Development of the Mini Excavator KX027-4 for European MarketConstruction Machinery Engineering Dept. for Excavator

In Europe's mini backhoe market, there is a high demand for machines in the 2-3 ton range with 10 000 units sold per year. In 2014, Kubota acquired a high share of this market segment with its 2.6 ton minimum tail swing excavator. To increase market share, we developed a 2.6 ton conventional tail swing compact excavator. Because of the physical size of European operators, there is a need in the European market to expand the 'living" space around the driver's seat. Accordingly, in the development of the KX027 we decided to increase the cabin size to enhance safety and provide a secure working environment. Because there are limitations on the weight of the KX027-4 for shipping, it is difficult to increase cabin size without increasing the cabin weight. In this paper, we explain the development of the KX027-4 aluminium cabin that allows the cabin size to be increased to better accommodate the operator comfortably while saving weight at the same time.

- Mini Backhoe

- Cabin

- Aluminium Alloy

- Increased "Living" Space

- Weight Saving

- 【Related SDGs】

-

Development of Commercial Humidified Air Purifier “Purewasher”Precision Equipment Engineering Dept.

The demand for air purifiers to improve room air quality has increased. To enter the market for commercial humidified air purifiers, for which growth can be expected in the future, we developed the commercial humidified air purifier “Purewasher”. We applied technology for spraying water actually used for air conditioning in clean rooms, and we downsized the air washer. We utilized slightly acidic electrolyzed water to eliminate bacteria. We consider these to be the core technologies of Purewasher. We proceeded with development emphasizing the above technologies, maintainability, and design. A performance evaluation of the product yielded the following results: bacterial eradication rate: 99%; gas odor reduction: over 90%; and humidification capacity: 2.7kg/h(20ºCDB•30%RH). This product successfully completed the development process and we entered the market for commercial humidified air purifiers.

- Air Purifier

- Air Washer

- Slightly Acidic Electrolyzed Water

- Humidification

- Bacteria Elimination

- Deodorization

- 【Related SDGs】

-

Water & Environment

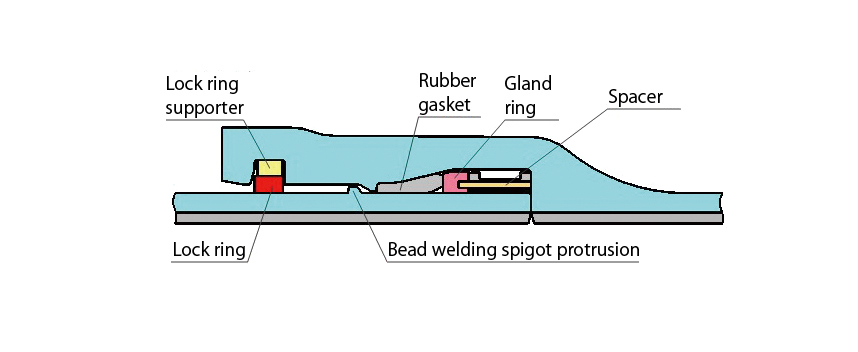

Development of New Earthquake-Resistant Ductile Iron Pipe US-R Type for Piping in Shield TunnelPipe Systems Networks R&D Dept.

Recently, many large-diameter water pipeline renewal projects are being planned for large-scale water supply utilities. Construction of a large-diameter pipeline is often performed in a shield tunnel constructed under the road, and earthquake-resistant ductile iron pipes US type, which have a proven record, have been adopted to date. However, as competition in the steel pipe sector intensified, we got some hints from customers about improving the US type, such as shortening the construction period and reducing the installation cost at the curved sections of the shield tunnel. In order to respond to their demands, we developed a new earthquake-resistant ductile iron pipe, the “US-R type”.

- New Rubber Gasket

- Lock Ring Supporter

- Angled Straight Pipe

- Shortening the Construction Period

- Reduction of Pipeline Laying Cost

- 【Related SDGs】

-

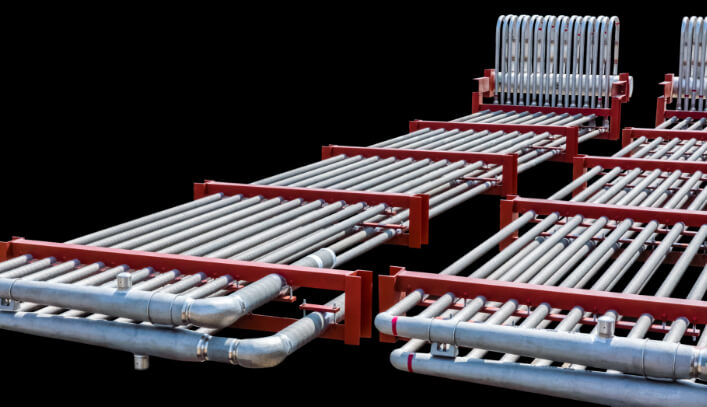

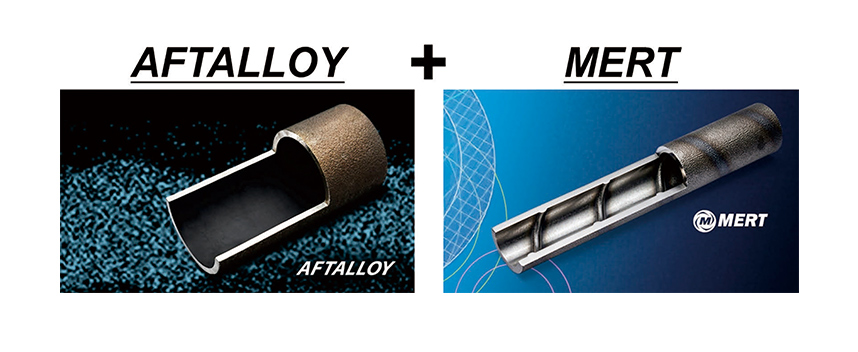

Development of AFTALLOY+MERT as a Cracking Tube for Ethylene ProductionSteel Castings Technology Dept.

Cracking tubes are a key part of an ethylene plant in the petrochemical industry. Recently, there has been an increase in the number of plants, especially ethane cracking furnaces, adopting alumina forming tubes because highly efficient production can be expected due to their coking- and carburizing-resistant properties. On the other hand, Kubota's proprietary technology, MERT (Mixing Element Radiant Tube), has been adopted in over 600 furnaces, mainly naphtha furnaces, since MERT was developed about 20 years ago. Therefore we have developed a top level functional product "AFTALLOY+MERT" which is a combination of AFTALLOY (Kubota’s alumina forming tubes) and MERT technology. It has been installed in a commercial ethane cracking furnace of a major ethylene producer for performance evaluation. The results of the evaluation verified the excellent properties of the new product compared with the original MERT. In this paper, we report on our development activities and the results.

- Cracking Tube

- Coking

- Mixing Element

- Plasma Powder Arc Welding

- Alumina Forming

- 【Related SDGs】

-

Development of the Energy-saving Cylindrical Dewatering CentrifugeEnvironmental Engineering Dept.

In recent years, initiatives to save energy have become an urgent issue in the sewerage business, and sewage treatment facilities needs to reduce energy consumption more than ever. Dewatering centrifuges, used in the treatment sewage sludge, are widely used because they have such features as being resistant to fluctuations in sludge properties, are highly suitable for treating difficult-to-dewater sludge, capable of large-scale treatment, and are characterized by their high processing stability. However, on the other hand, compared with other dehydration methods, power consumption is high, and further reduction in power consumption is an issue. Kubota' cylindrical dewatering centrifuge has become a major player in the environmental plant business, and has been highly evaluated for its dewatering performance. In this paper, we report the development of an energy-saving cylindrical dewatering centrifuge which has the lowest power consumption in the industry.。

- Sewer

- Centrifugal Force

- Dewatering Machine

- Moisture Content

- Energy-saving

- 【Related SDGs】

-

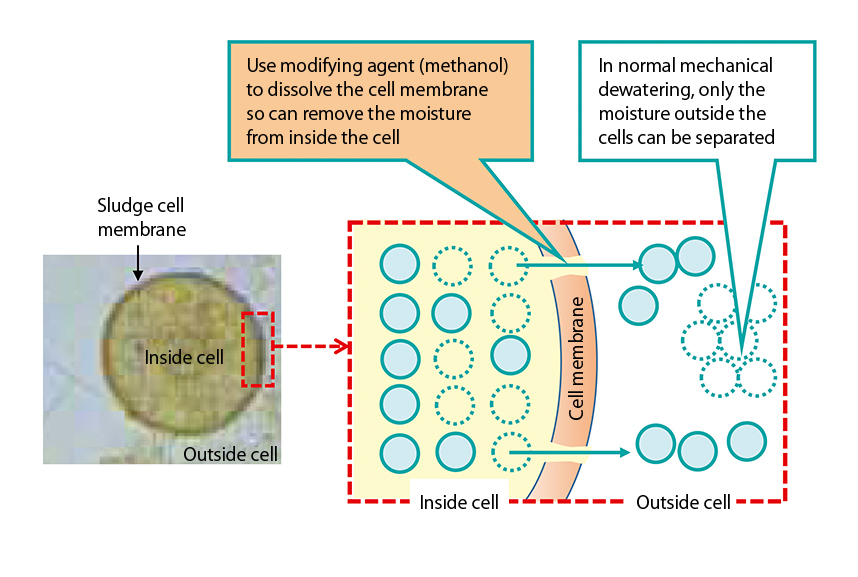

Development of Energy-saving Fertilizer Technology by Non-heat Reforming of Sewage Dewatered SludgeWater and Environment R&D Dept. III

We have developed a new sludge fertilizer technology that can reduce the moisture content of sewage sludge to the same level as that obtained using conventional heat-drying technologies without requiring a high temperature heat source. The dewatered sludge is modified at room temperature with commonly used chemicals and physically compressed at temperatures below 90ºC. Due to most of the water in the sludge being removed in liquid form, this technology is superior in terms of energy saving compared to heat-drying technology that evaporates water in the sludge. In addition, by applying this technology, the product can also be used as a fertilizer, and the growth and yield of the crop were higher compared to the case where conventional sludge fertilizer was used. Since small and medium-sized sewage treatment plants are facing severe financial difficulties, low lifecycle costs (LCC) are required at the time of the installation and replacement of facilities. This technology has a lower LCC than conventional sludge fertilizer technology due to the implementation of a new energy-efficient approach, which makes small and medium-sized sewage treatment plants cost competitive.

- Sewage Sludge

- Energy Saving

- Fertilizer

- 【Related SDGs】

-

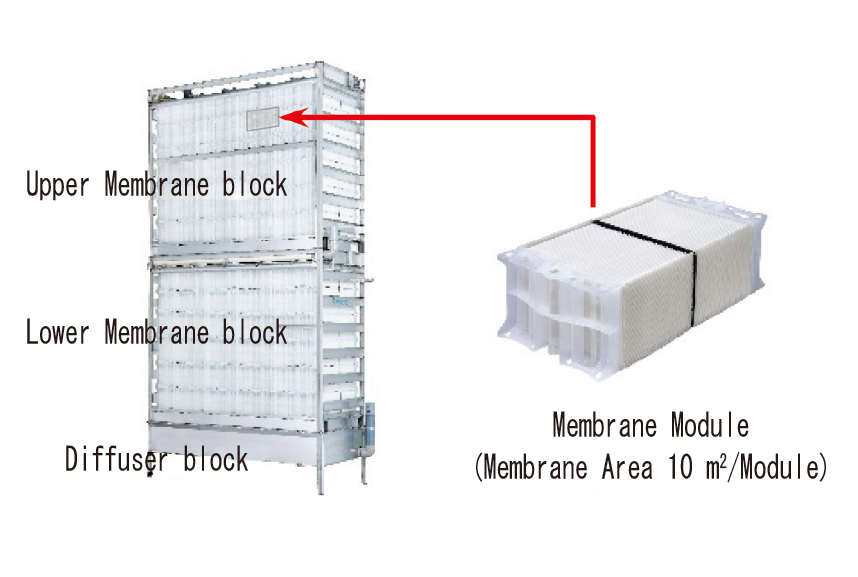

Application of Submerged Membrane SP to Industrial WastewaterMembrane Systems Dept.

Since its launch in 2011, SP models of the Submerged Membrane Unit have been installed in approximately 50 projects in the sewage treatment industry in North America, Europe, the Middle East, Japan and other countries. In 2017, Kubota conducted a pilot test using SP models at one of the major food processing companies in Japan in order to promote these models to the mid- and large-scale industrial wastewater market. During the test, design parameters and maintenance requirements were confirmed. The pilot test was successful and the food processing company became the first ever customer in the industrial wastewater market to adopt SP models. In this report, the efforts and activities involved in optimizing SP models for the industrial wastewater market are described.

- Membrane Bio Reactor (MBR)

- KUBOTA Submerged Membrane Unit®

- Industrial Wastewater

- 【Related SDGs】

-

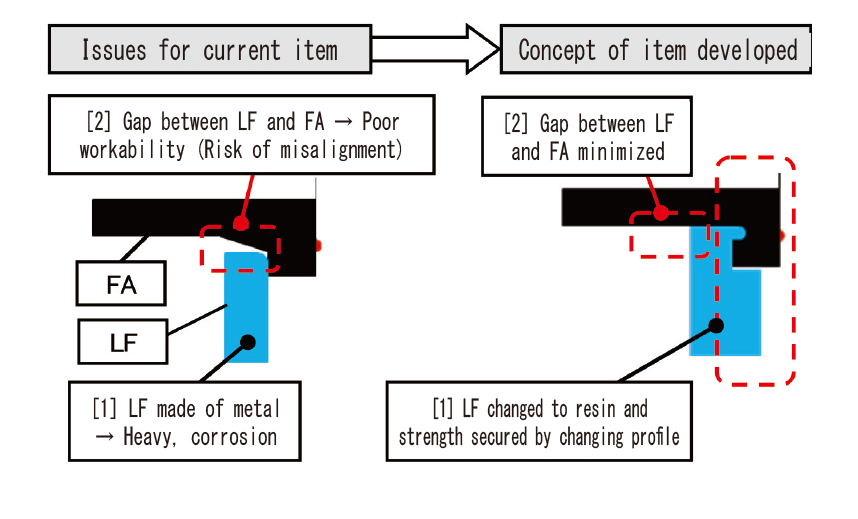

Development of All-plastic FlangeKubota ChemiX Co., Ltd.

Almost 50 years have passed since many factories were built during Japan's high growth period. Now there are concerns that corrosion is affecting the metal pipes used in those factories due to the fact that the factories were built in coastal areas and a long time has elapsed since their construction. Kubota ChemiX is entering the factory pipeline market with its polyethylene pipes and fittings that are easier to install and have anti-corrosion properties. However, the currently used flange has metal components that make it vulnerable to corrosion. This report describes the development process for an allplastic flange which is easier to install and is corrosion resistant.

- Pressured Pipeline

- Flange

- Fiber-reinforced Resin

- Corrosion

- 【Related SDGs】

-

New Products

- Cloud-type Pipeline Management System [WATERS-Cloud]

- AI taking the place of humans in analyzing data and detecting abnormal operations “Manhole Pump AI Abnormal Operation Detection System”