KUBOTA TECHNICAL REPORT No.55 JANUARY 2022

In 2021, we launched our newly formulated long-term vision GMB2030. Becoming an “‘Essentials Innovator for Supporting Life,’ Committed to a Prosperous Society and Cycle of Nature,” which is the type of company Kubota is aiming to be in 2030 as envisioned in GMB2030, means that we will continue to provide indispensable value to society by offering total solutions that combine our products, technologies, and services. We will contribute to building a prosperous and sustainable society in the areas of food, water, and the environment, which are indispensable for human life, and thereby contribute to the achievement of the SDGs. In this issue of Kubota Technical Report No. 55, you will find Kubota’s technologies that contribute to society by listening thoroughly to the voices of various people at worksites around the world. We hope you will take the time to read it.

Farm & Industrial Machinery

Development of Tractors for Local Production in IndiaCompact Tractor Engineering Dept. / Materials & Castings Center / Analysis Center

KUBOTA Research and Development Asia Co., Ltd.

Kubota started selling MU series tractors to India in 2015 with the MU5501 followed by the MU4501 in 2017, but at the time, Kubota did not have a production base in India and was exporting tractors from its plant in Thailand. As a result, parts procurement and logistics costs were reflected in the sales price, making the products more expensive than those of local manufacturers despite their good performance. Given these circumstances, Kubota established a tractor manufacturing company in India in 2019 as a joint venture with Escorts Limited, a major Indian tractor manufacturer, and started production of MU4501 tractors at the Indian plant in 2020. In this paper, we will focus on the technologies, especially transmission parts, to maintain the quality level cultivated through the development of tractors for local production in India, and to procure and produce these parts locally in India.

- Tractor

- Multi-purpose

- India

- Material Evaluation

- Noise Analysis

- 【Related SDGs】

-

Development of M6002 Series Tractor for EuropeAgricultural Tractor Engineering Dept. / Farm and Industrial Machinery R&D Dept. Ⅲ

Hydraulic Equipment Engineering Dept. / Analysis Center

A growing world population has resulted in a rapidly increasing demand for food. Thus, the need for agricultural machinery has increased, given that it plays an important role in stabilizing the food supply. A key feature of European agriculture is the use of cutting edge technology to attain high crop yields. Kubota had already introduced the 97-127 kW rated M7 series tractor in response to these needs for large row-crop operations. The majority of medium sized operations in Europe are mixed farmers who both produce crops and raise livestock, sometimes using the crops as feed. Among these farmers, high yield per-hectare and ease of use are important. In addition to the M7, Kubota has now developed the 91-106 kW rated M6002 series tractors for the European market with a particular focus on being a good fit for mixed farmers.

- Control Lever Layout

- Closed Center Load Sensing Hydraulic System

- 【Related SDGs】

-

Development of Green Soybean Combine HarvesterCombine Harvester Engineering Dept.

In recent years, the production of green soybeans has been increasing because of the conversion from rice cultivation in Japan. Kubota sells walk-behind green soybean pulling machines, but an additional threshing machine is necessary, and low efficiency is a bottleneck. There is increasing demand for a harvester having both high precision and high efficiency. Kubota has developed “high-precision, high-efficiency green soybeans combine” with the cooperation of the Akita Prefectural Agricultural Experiment Station, which is situated in the main production area for green soybeans in Japan. This paper introduces the development technology that achieves both high accuracy and high efficiency.

- Green Soybean Combine

- Vegetable Harvester

- Feed Chain

- Pass

- High Accuracy

- High Efficiency

- 【Related SDGs】

-

Development of Corn Harvesting Header CH70 for DC70 Combine HarvesterKUBOTA Research and Development Asia Co., Ltd.

There is growing demand within ASEAN countries for better harvesting performance for grain corn along with the growing market for this product due to government-supported policies to achieve self-sufficiency through domestic production and reducing imports. The customer need perfect harvester that can be enhancing about working capacity, low fuel consumption, low header loss, lodged corn harvesting ability to support working. Corn header is one of solution of the enhance requirement.

KUBOTA Research and Development Asia (KRDA) developed corn header CH70 focusing on greater compactness & flexible size, a header that is lightweight and easy to install, that supports the global policy of zero burn after harvest, has a reasonable price, and with performance superior to all other competitors. Due to its special features, corn header CH70 helps the customer to reduce operational costs and generate a higher income compared to the harvesters of competitors. CH70 can meet the above requirements and can also increase the market share of Kubota’s harvesting machines in ASEAN countries, as well as increasing sales and expanding marketing networks to support the future business growth of both customers and Kubota.

- Corn Header

- Combine Harvester

- Compact

- Blade shape

- Zero burn

- 【Related SDGs】

-

Development of Ride-on Two-row Fully Automatic Vegetable TransplanterTransplanter Engineering Dept.

In domestic agriculture, rice farmers who are accustomed to ride-on machines are stepping up their efforts to grow highly profitable vegetables due to the slump in rice prices. In addition, the scale of farms is increasing, and there is a growing demand for a highly efficient and easy-to-use fully automatic ride-on vegetable transplanter. On the other hand, Kubota did not have a line-up ride-on machines that could meet this demand. Given these circumstances, we have developed a new two-row fully automatic ride-on vegetable transplanter. This paper describes the technology we developed made possible “high planting performance” and “easy handling performance”, which are in especially high demand.

- Vegetable Transplanter

- Planting Performance

- Handling Performance

- Structure for Controlling Planting Depth

- 【Related SDGs】

-

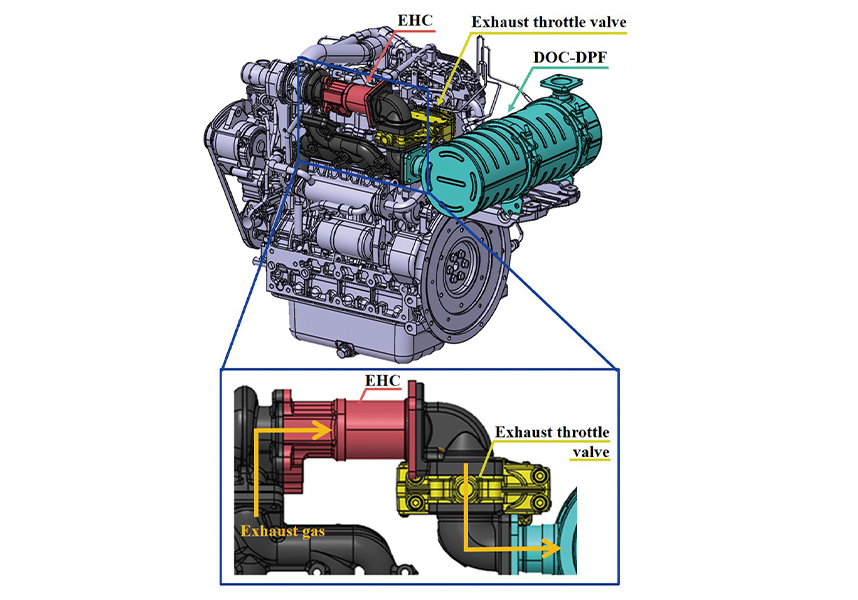

Development of DPF Regeneration System Under All Operating Conditions for GeneratorsEngine Engineering Dept. Ⅰ

As the global emission regulations have become more stringent recently, a DPF that filters PM in exhaust gas is becoming essential for diesel engines. Engines equipped with a DPF must carry out DPF regeneration that burns and removes PM, but generator engines that operate unmanned cannot be stopped during DPF regeneration. Therefore, it is required that a DPF can be regenerated under all operating conditions even where the exhaust temperature is low. In this study, the development of Kubota’s original exhaust gas heating system using an exhaust heating catalyst and exhaust throttle enables regeneration under all operating conditions. In addition, this study solved the problem that low load operation sometime causes both white smoke and DOC clogged during generator use.

- Diesel Engine

- Electrical Generator

- PM

- DOC

- DPF

- Exhaust Heating Catalyst

- Exhaust Throttle Valve

- 【Related SDGs】

-

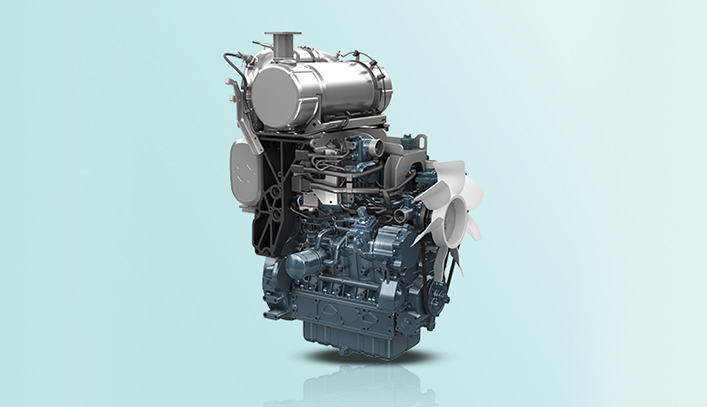

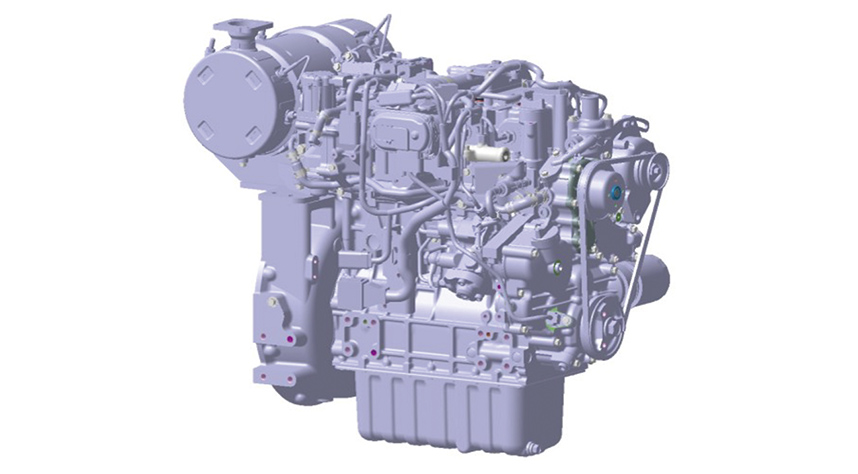

Development of V1505T Engine with Common Rail Fuel Injection SystemEngine Engineering Dept. Ⅰ

05 series engines are the leaders in our engine business. They are installed on Kubota’s agricultural, construction and OEM machines. The V1505 Turbocharged (V1505T) engine is the high-end model of 05 series having features not found in competitors’ products such as low vibration due to its small size and four-cylinder configuration. EU Stage V emissions regulations have been enforced since 2019 and the regulation value has been significantly strengthened. In order to secure business volume and further expand sales in the European market, we have developed the V1505T common rail engine. Here we describe our approach to achieve DI combustion with the smallest cylinder bore and to realize a compactness comparable to a competitor’s 3-cylinder engine.

- V1505T

- Common Rail System

- DI Combustion

- Small Cylinder Bore

- Compactness

- 【Related SDGs】

-

Development of the Mini Excavator RDL3 Series for European MarketConstruction Machinery Engineering Dept. for Excavator / Construction Machinery Base Technology Engineering Dept.

The mini excavator RDL3 series for the European market is new model 5 to 5.5t class machine that complies with European Stage V emission regulations. Inheriting the basic performance of the previous model, which was well received by the market, such as operability, stability, durability, lifting capacity, and digging power, the new model delivers the comfort that has been strongly demanded by the market in recent years and upgrades the equipment to increase product competitiveness and expand market share. In terms of comfort, we have achieved the industry’s top class quietness (ear noise) for mini backhoes. In the equipment upgrade, we have developed a new user interface (UI) that can be operated intuitively.

- Mini Backhoe

- European Emission Regulations Stage V

- Ear Noise

- User Interface

- 【Related SDGs】

-

Development of Slope Grass Cutter “GC-M500”Farm Machinery Implements and Products Engineering Dept. / Analysis Center

Slope grass cutters have become popular as a product that improves the efficiency and safety of mowing operations. On the other hand, as the number of farmers expanding the scale of their farms is increasing, the operating hours of slope grass cutters is also increasing, and it is necessary to further improve work efficiency and durability. Therefore, we developed the slope grass cutter GC-M500 for professionals.

By selecting the maximum engine speed from two stages in the “Master mode”, it is possible to work under various conditions. Because of its features, an operator can reduce physical discomfort and the working time. In addition, he can reduce downtime and improve productivity due to the product’s high durability.

- Slope grass cutter

- Master mode

- Blade mounting method

- Easy maintenance

- Long-life blade

- 【Related SDGs】

-

Development of Micro Flow Rate NX FeederPrecision Equipment Engineering Dept.

A feeder is a device for continuously supplying a constant flow rate of various powdery and granular materials in order to meet specific resin mixing ratios. Conventionally, resin products have been produced in process by blending a small amount of additives with other materials in advance and supplying them from a feeder to an extruder. On the other hand, in order to improve productivity, there was a need to eliminate the prior blending process and to add a trace amount directly to the extruder. In response, we have developed a new micro NX feeder. The NX feeder series is a proprietary feeder developed by Kubota. In addition to making use of its structural features, we have developed technologies to improve the supply accuracy, expand the flow rate range, expand the range of applicable materials, reduce the installation area, and achieve the target specifications. This paper explains these development technologies.

- Feeder

- High Supply Accuracy

- Micro Flow Rate

- Supply of Very Small Amount

- High Accurately Weigh and High Stability

- Bridge Material

- 【Related SDGs】

-

Water & Environment

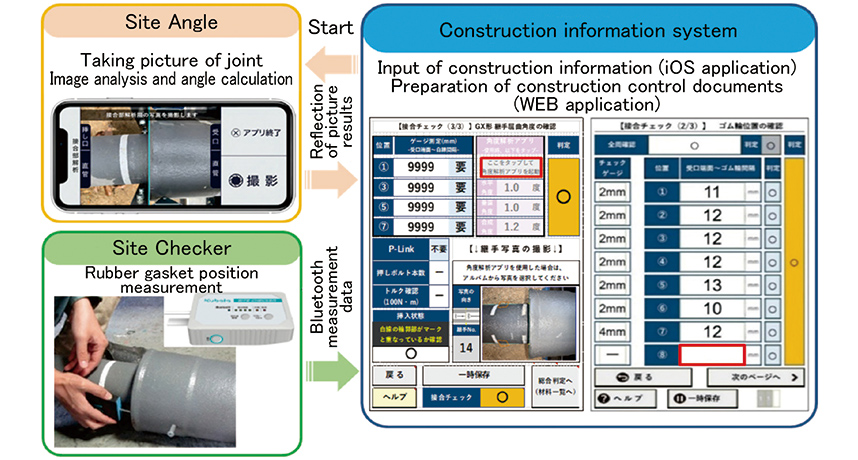

Development of Water Work Information System for Water Pipe ConstructionPipe Systems Networks R&D Dept.

Despite efforts to renew and build earthquake-resistant pipelines, the ratio of aging pipes increases year by year, so acceleration of renewal is required. However, in addition to manpower shortage, construction companies spend a lot of time on various documents to submit. On the other hand, water utilities are concerned about the drop in level of the construction management, and require secure jointing work according to the manual and reliable measurement records. In order to solve these problems, we have developed “Water work information system (WWIS)”, “Site Checker” and “Site Angle”. WWIS can encourage secure works and automatically create documents using portable terminals, Site Checker can measure positions of a rubber gasket and send to WWIS, and Site Angle can automatically measure joint deflection angles.

- water pipe construction

- earthquake-resistant ductile iron pipe

- IoT

- improvement of quality and efficiency of constructions

- 【Related SDGs】

-

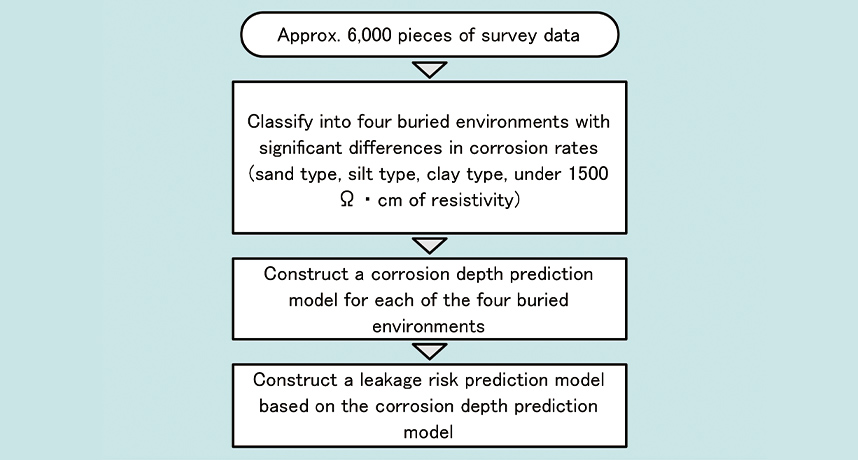

Development of Highly Accurate Method for Predicting the Degree of Deterioration in Water PipesPipe Systems Networks R&D Dept. / Technology Innovation R&D Dept. Ⅰ

There are many domestic water pipes that need to be replaced. Although water utilities need to maintain pipelines to a high standard, pipe replacement has been actually delayed because it is difficult to evaluate the extent to which buried pipes have deteriorated, and there are no clear guidelines on how to evaluate pipe deterioration. Then, as part of an initiative to promote pipe replacement, using approx. 6000 of the accumulated survey data, we have developed a method that can predict the degree of deterioration in water pipelines with high accuracy. The method considers both variation and lag time of corrosion, and predicts pipe deterioration quantitatively as leakage probability (number/year/km).

- Ductile and Cast Iron Pipe

- Degree of Deterioration in Water Pipes

- Pipe Replacement

- 【Related SDGs】

-

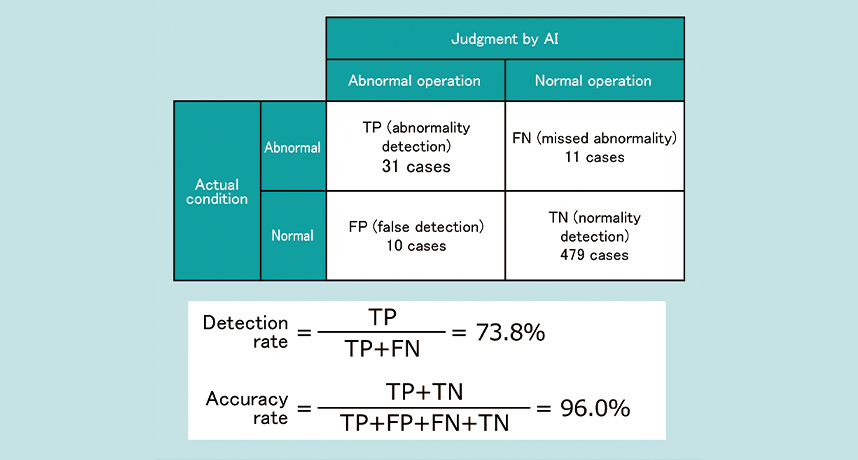

Development of Manhole Pump AI Abnormal Operation Detection SystemWater and Environment R&D Dept. Ⅰ / Environmental Engineering Design and Procurement Dept.

Environmental Engineering Dept. / EU Innovation Center

For manhole pumps for sewage pumping, which are distributed over a wide area, the adoption of cloud monitoring systems has increased recently in order to improve management efficiency. However, due to the huge amount of operational data acquired, it is difficult for maintenance managers to check daily, and even if an abnormal operating condition occurs, they are not aware of it and are forced to take emergency measures after a failure occurs. Therefore, Kubota has developed an abnormal operation detection system using AI / machine learning technology. Since AI analyzes operation data on behalf of humans and notifies abnormal conditions, maintenance managers can perform efficient preventive maintenance. In this paper, in addition to the details of the two AI functions developed, the effectiveness of these functions demonstrated in the B-DASH project of the MLIT will be described.

- AI

- Machine Learning

- IoT

- Manhole Pump

- Preventive Maintenance

- 【Related SDGs】

-

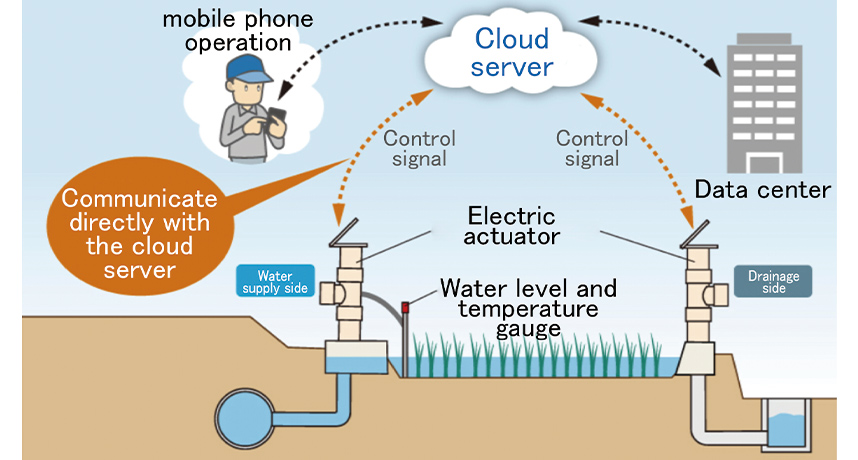

Development of “WATARAS” (LTE-M), Water Remote Management System in Paddy Fields without Gateway DeviceWater and Environment R&D Dept. Ⅰ / Kubota ChemiX Co., Ltd. R&D Dept.

The water remote management system “WATARAS” can remotely and automatically control the water supply and drainage of paddy fields while monitoring them with a mobile phone or personal computer. The benefits include reducing manhours spent on water management, conserving water resources, and digitizing and utilizing water management. The direct communication (LTE-M: LTE Cat.M1) type reported in this article is a communication method in which the electric actuator installed in the paddy field connects directly to the public radio wave (cellular wave), and it does not require a gateway device that is indispensable for existing products. It can be installed and used in remote or mountainous areas; something that was difficult until now.

- paddy fields

- WATARAS

- water management

- remote area

- mountainous area

- LTE-M

- LTE Cat.M1

- IoT

- gateway

- reducing manhours spent on water management

- saving water

- 【Related SDGs】

-

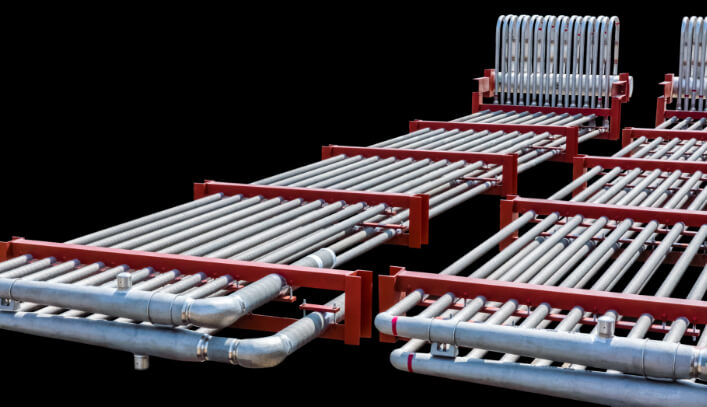

Development of High-Efficiency Denitrification MBR (LOOP MBR) that Reduces Costs, Energy, SpaceEnvironmental Engineering Dept.

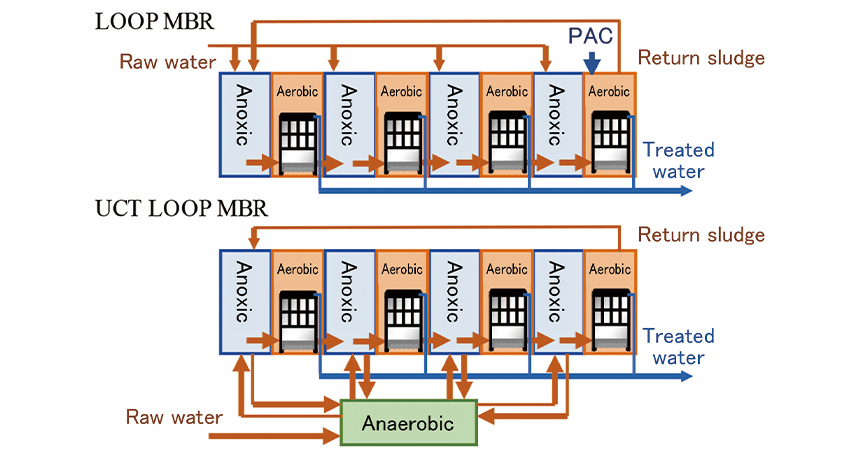

Sewage treatment plants whose discharge destination includes closed water areas are required to remove nitrogen, and a discharge regulation of <5 mg/L of T-N in treated water is set for some facilities. The conventional advanced treatment process for such high-efficiency denitrification significantly increases the treatment cost, power consumption, and installation space compared to the secondary treatment process, such as conventional activated sludge process. To solve this, we have developed a new MBR enabling high-efficiency denitrification that saves cost, energy, and space. This method enables the denitrification of ≈3 mg/L of T-N using multistep processing that arranges four sets of single-step MBRs in series; each having one anoxic tank and one aerobic tank. By eliminating the need to install a postdenitrification tank and by integrating the aerobic tank and membrane tank, construction costs for civil engineering and blower facilities as well as air diffusion amount can be reduced. Moreover, operating this method with the existing secondary treatment process in the advanced treatment is expected to decrease the cost and construction period required for advanced treatment to comply with the regulation equivalent to ≤10 mg/L of T-N.

- MBR

- Cost-Saving

- Energy-Saving

- Space-Saving

- High-Efficiency Denitrification

- 【Related SDGs】

-

Development of Fermentation Technology for Household GarbageWater and Environment R&D Dept. Ⅲ / Carbon Neutral Promotion Dept.

The combined system, which recovers biogas by separating garbage and paper garbage from combustible garbage and subjecting it to fermentation, and incinerates nondegradable materials such as plastics and wood has the advantage of being able to effectively utilize the energy of the waste. However, the introduction of the combined system has not proceeded smoothly due to the problem of life cycle cost (LCC) compared with the conventional incineration system. This development aims to solve the problems of existing combined systems by (1) highly efficient pretreatment, (2) an original vertical fermenter, and (3) dewatering residue. As a result, the developed system achieved a lower LCC than the incineration system, making it easier for local governments to introduce the system. By popularizing this system, which can reduce CO2 emissions by biogas power generation, it is possible to contribute to CO2 emissions reduction and resource circulation.

- CO2 Emission Reduction

- Resources Circulation

- Household Garbage

- Methane Fermentation

- 【Related SDGs】

-

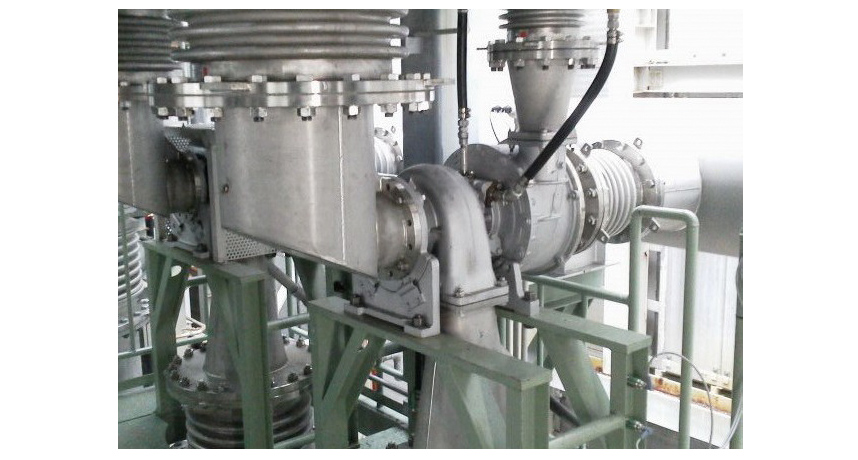

Development of Energy-saving Technology Utilizing a Turbocharger for Sewage Sludge Incineration FacilityEnvironmental Engineering Design and Procurement Dept.

In recent years, there has been an increasing need for energy saving technology from the viewpoint of global environmental conservation, and sewage treatment plants are no exception. Fluidized bed incinerators have been widely used as sewage sludge volume reduction technology, but the high consumption of electricity has been an issue. We developed a method utilizing a turbocharger that significantly reduces the amount of electricity consumed by a sludge incineration facility.

- Energy Saving Technology

- Turbocharger

- Fluidized Bed Incinerator

- Sludge Disposal

- 【Related SDGs】

-

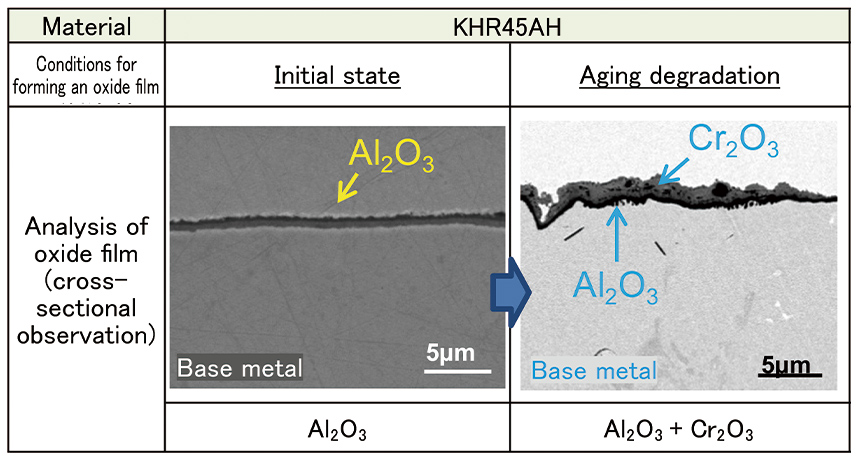

Development of 45% Nickel-based Aluminum-containing Material for Cracking Tube MarketSteel Castings Technology Dept.

In the cracking tube market for ethylene production, a growing number of customers use materials containing Al (aluminum) which are high value added products. Kubota’s Al-containing material is based on 35 Ni (nickel) with high creep rupture strength in order to prevent tube deformation. However, some customers prefer 45 Ni material because carburizing resistance is more important than preventing tube deformation. In order to meet a variety of customer needs, we designed an alloy aiming to improve the carburizing resistance performance required by customers and provide good weldability for on-site welding. Also, we developed a product with the same cost and shorter delivery time as the current 35 Ni based Al-containing material by streamlining a part of the manufacturing process of the current Al-containing material.

- Cracking Tube

- Carburizing Resistance

- Al-Containing Material

- Alumina Forming

- Customer’s On-Site Welding

- 【Related SDGs】

-

Introduction Article

- Introduction of Water Infrastructure Development Projects in Asia

- Introduction of Technique Effectively Using Byproduct Salt in a Landfill Disposal Site