KUBOTA TECHNICAL REPORT No.57 JANUARY 2025

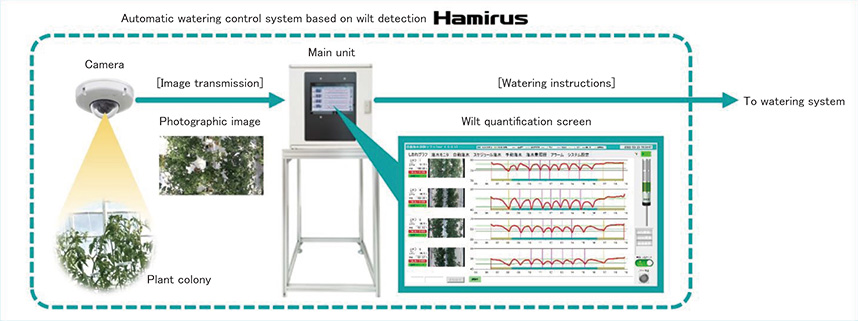

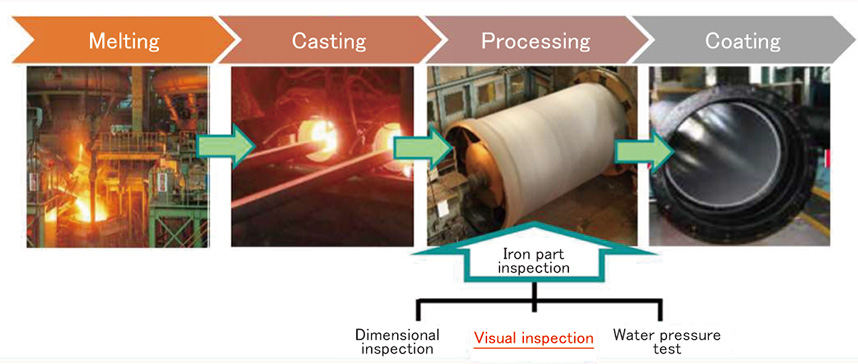

At Kubota, we have set 2024 as the beginning year of our journey to advance AI integration, not just in research and development, but throughout the company, including manufacturing and sales. Our company was a global pioneer in achieving automation of key agricultural machinery, including tractors, combine harvesters, and rice transplanters. This 57th issue of the Kubota Technical Report highlights innovations developed using AI technology such as the industry’s first autonomous combine harvester and the withering detection-based automated irrigation control system. It also covers the technology for detecting defects on ductile iron pipe surfaces using AI image analysis. We hope you will take the time to read it.

Farm & Industrial Machinery

Development of the Compact Tractor ST Series for the Domestic MarketCore Platform Engineering Dept. / Tractor Engineering Dept. ⅠFarm and Industrial Machinery R&D Dept. Ⅲ

The total domestic demand for tractors is on a declining trend, but tractors with 20 to 40 horsepower still represent a significant volume zone, accounting for more than half of the total demand. Many users of small tractors in this horsepower range are part-time, small-scale farmers, and a high percentage of them are elderly. Therefore, there is a demand for affordable and easy-to-use products. In response, Kubota has developed the ST series, a fully redesigned model, to achieve even greater operability at a low price. This paper discusses the development technology of the electronically controlled HST, which is being introduced in this class for the first time by Kubota.

- Tractor

- Electric Control

- Hydro Static Transmission

- 【Related SDGs】

-

Development of the Method for Durability Improvement by Using Drive SimulationAnalysis Center

In recent years, the farm and industrial machinery consolidated department has aimed to expand our product lineup for farming tractors in Europe and the high-speed utility vehicle (UV) market in North America. It is difficult to ensure the durability of the body. Because the tractors can be used for various highload operations in farming, the load of the UV is unclear when driving on rough roads. In the past, products were developed by repeating a design based on experience and durability tests on actual machines, but this experience may not apply for new markets. Additionally, our previous analysis method needs the load condition, calculated by using actual measurement, so its measurement needs a lot of time and we cannot determine the optimal design. Therefore, we have developed an analysis method that can calculate the load which is applied to the vehicle, and consider the improvement of durability by performing virtual work on a simulation.

- Tractor

- Electric Control

- Hydro Static Transmission

- 【Related SDGs】

-

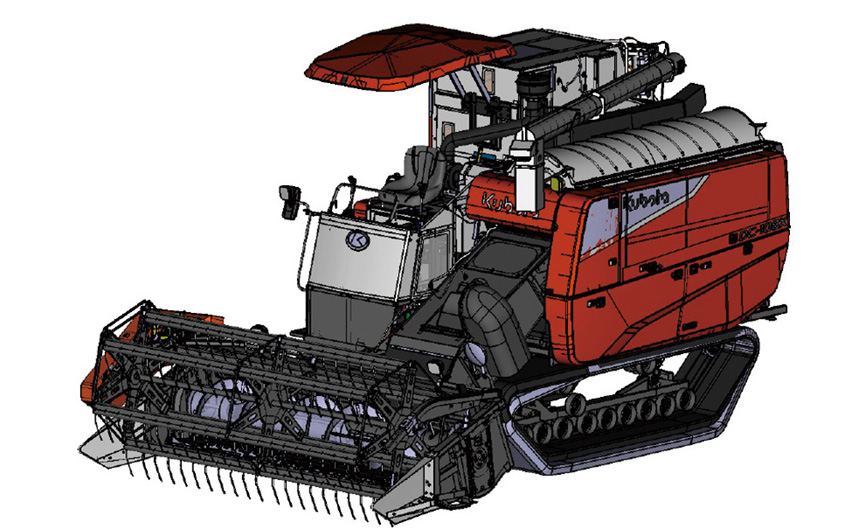

Development of the Combine Harvester DC-120X for ThailandCombine Harvester Engineering Dept. / Analysis Center

Kubota has acquired the top share in the Thailand combine harvester market in terms of sales volume. However, the market share remains relatively low in the harvesting area in the main north-eastern region. This is due to the strong popularity of machines manufactured by other companies in Thailand, which have high work efficiency in spite of the adverse conditions of the long-culm lodging rice and deep wet fields that are prevalent in the north-eastern region. Therefore, we developed a new model to improve “longculm lodging performance” and “wet field performance” with a 2-pump 2-motor transmission, aiming to improve work efficiency under adverse conditions.

- Combine Harvester

- Long-culm Lodging Rice

- Wet Field

- 2P2M T/M

- 【Related SDGs】

-

Development of the Unmanned Autonomous Combine Harvester “DRH1200A-A”Farm and Industrial Machinery R&D Dept. Ⅵ/ Farm and Industrial Machinery R&D Dept. ⅠTechnology Innovation R&D Dept. Ⅱ/ Combine Harvester Engineering Dept.

The level of automatic operation of agricultural machines is roughly divided into three levels: Level 1 is automatic steering with the user on board, Level 2 is automatic operation with the user off board and monitoring from a visible location, and Level 3 is automatic operation with remote monitoring1). The combine harvester, which is run while harvesting rice and wheat, has problems such as monitoring the surrounding area during operation, a high level of difficulty in operation, and continuity of operation. It was difficult to achieve Level 2, but advanced technology and control technology overcame these problems and succeeded in commercialization. This paper introduces the obstacle detection technology in the working environment and the technology to automate reaping work, as well as the technology to improve the efficiency of automatic operation work, which were developed to realize this automatic operation Level 2 combine.

- Combine Harvester

- Autonomous Driving

- Obstacle Detection

- 2D-LiDAR

- Millimeter-wave Radar

- 【Related SDGs】

-

Development of the Riding Type Rice Transplanter KA Series for ChinaTransplanter Engineering Dept. / Analysis Center

In the Chinese market, the main stream is contractors, in which farmers entrust rice transplanting to companies. Larger machines with higher efficiency are needed against the backdrop of an expansion in the scale of wage planting and a shortage of labor due to a declining rural population. To meet these needs, we developed a riding type rice transplanter for China based on the concept of “a rice transplanter that can improve the efficiency of large-scale contract transplanters.” In this paper, we introduce the development of a wheel for improved paddy field driving and a new horizontal control mechanism for improved planting accuracy in order to cope with increasing size.

- Riding Type Rice Transplanter

- High Efficiency

- Planting Part Horizontal Control

- Analysis

- 【Related SDGs】

-

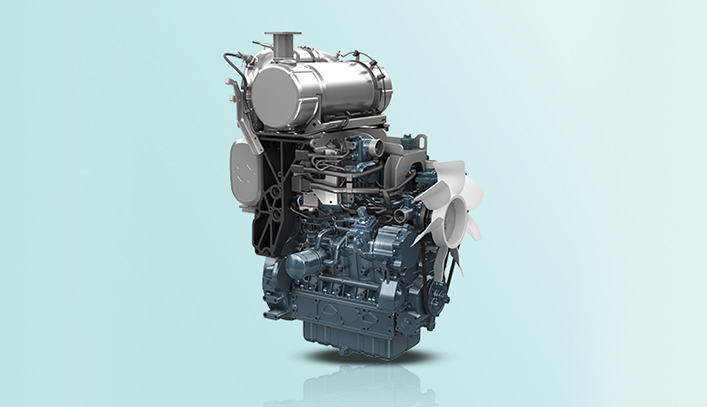

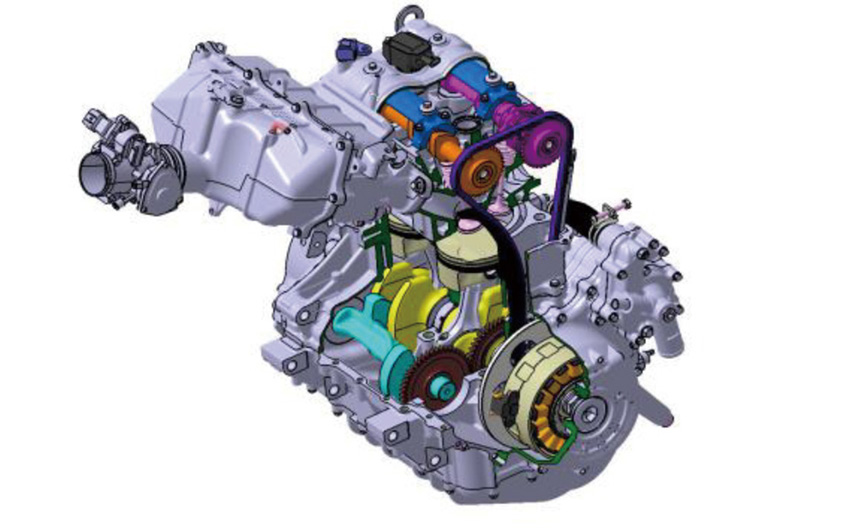

Development of the Gasoline Engine GZ850HEngine Engineering Dept. Ⅰ

Development of the gasoline engine GZ850H for use in the Utility Vehicle RTV-XG850 enabled us to expand our business domain. This is Kubota’s first development of a high-speed gasoline engine. The air intake system was changed from the conventional model to achieve higher output and lower fuel consumption. Competitiveness was strengthened by improving engine stall resistance. In order to comply with exhaust gas regulations, a new test method using intake pressure control was established, and efforts were made to ensure quality by measuring exhaust gas on a nonconsolidated basis at the engine.

- GZ850H

- High-speed Gasoline Engine

- Increased Output

- Improved Fuel Consumption

- Emission Regulation

- 【Related SDGs】

-

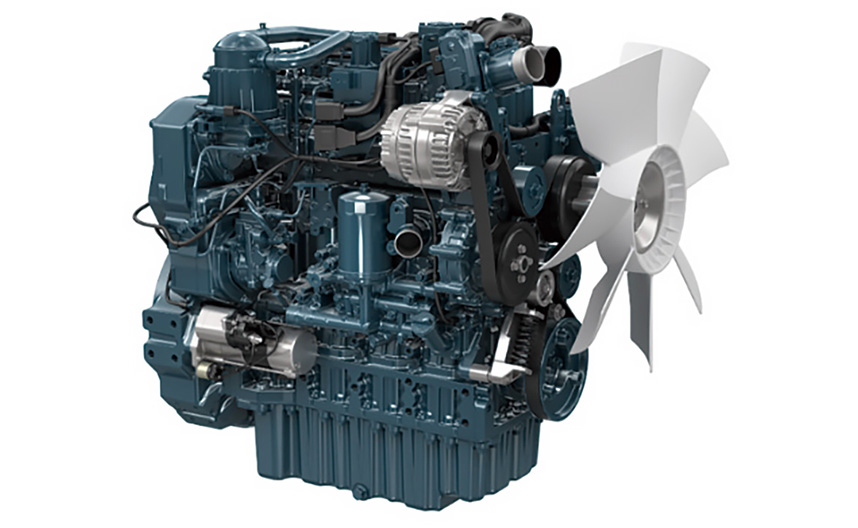

Development of the Diesel Engine for Industrial Use “V5009”Engine Engineering Dept. Ⅲ

The V5009 engine boasts 200 PS, the largest horsepower in the Kubota series. To achieve the market need for low fuel consumption performance, it incorporates a basic structural design that can withstand high cylinder pressure, and high boost control technology with a VG turbo. In terms of regulatory compliance, the European Stage V Emission regulations have been implemented from 2019, and DOC+DPF/SCR after-treatment technology has successfully reduced NOx/PM. In addition to the fuel consumption and emission reduction requirements, the V5009 has achieved durability in the severe environments specific to large engines, strengthening the product’s competitiveness.

- V5009

- High Cylinder Pressure Design

- High Power Density

- VG Turbo Technology

- 【Related SDGs】

-

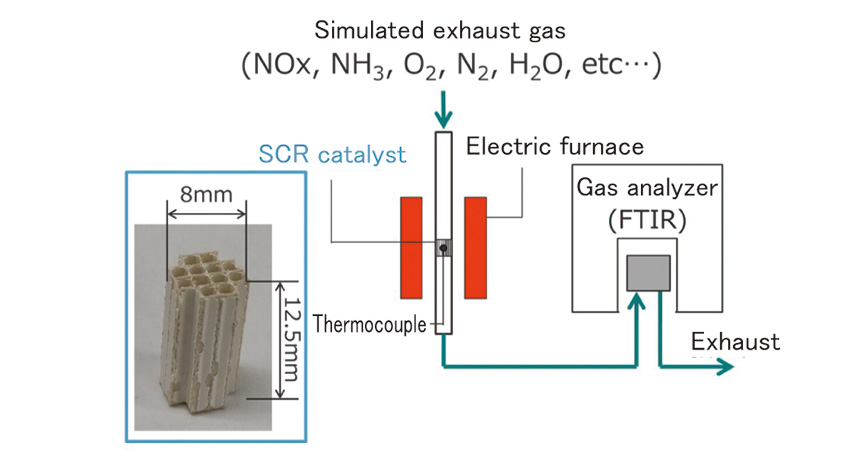

Development of SCR Catalyst Performance Degradation Prediction TechnologyEngine Engineering Dept. Ⅲ

The after-treatment system of the V3, 08, and 09 series engines, covering an output range of 56-155 kW, has adopted “DOC+DPF/SCR” in compliance with the EPA/CARB Final Tier 4 emission regulations implemented in 2014. The degradation of the SCR catalyst directly affects exhaust gas performance. We conducted research on the optimal SCR catalyst for general-purpose engines and developed a new copperbased catalyst with high robustness against catalyst degradation. The development of the new catalyst required long-duration endurance testing for degradation evaluation, but we utilized a degradation prediction method. This allowed us to shorten the development time.

- SCR

- Copper Catalyst

- Exhaust Gas

- After-treatment

- Catalyst Degradation

- Degradation Prediction

- 【Related SDGs】

-

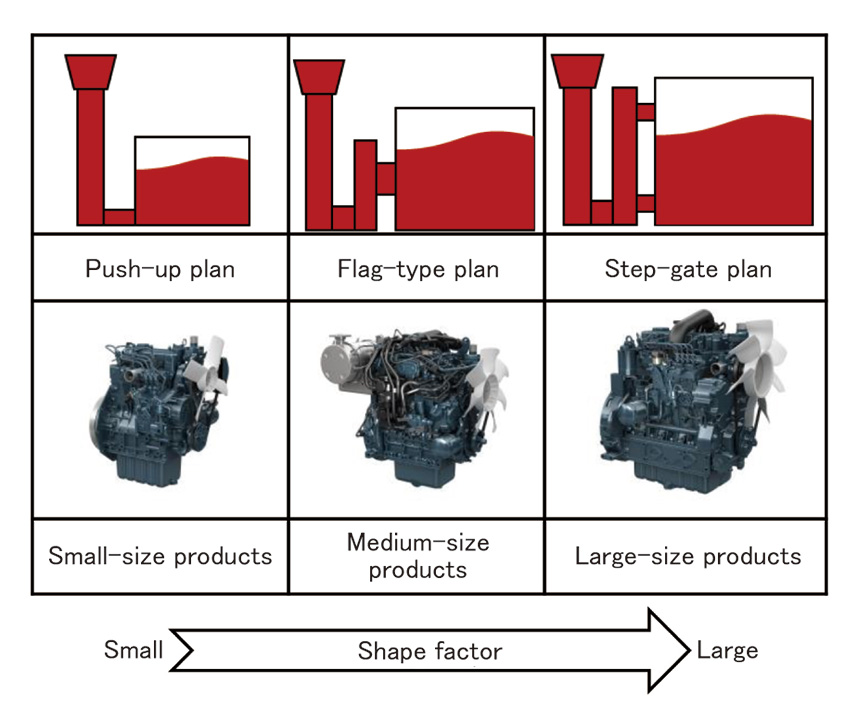

Establishment of Design Guidelines of Casting Plans for Large Engine CastingsMaterials & Castings Center / Machinery Castings Manufacturing Dept.

Engine castings are becoming larger, more complex in shape, and thinner-walled in recent years. On the other hand, as the shape factor (volume/minimum wall thickness) of engine castings increases, it becomes more difficult for molten metal to fill the mold quickly, so the gating system plans for castings have changed from the push-up plan to the flag-type plan and step-gate plan. Therefore, in this study, in order to establish design guidelines for the step-gate plan, we first clarified the effects of the sprue ratio and pouring velocity on the molten-metal filling behavior using methods such as flow simulation and water models, and then determined the appropriate sprue ratio range by verifying it through direct observation experiments.

- Engine Castings

- Gating System Plan

- Step Gate Plan

- Flow Simulation

- Filling Temperature

- Gating Ratio

- 【Related SDGs】

-

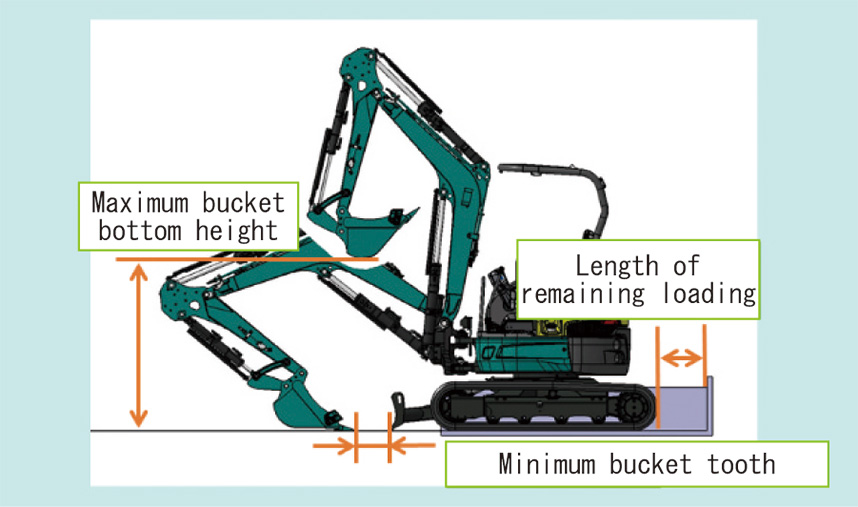

Development of the Expanding Working Range Technique for Mini ExcavatorsConstruction Machinery Base Technology Engineering Dept.Construction Machinery Engineering Dept. for Excavator

While the mini excavator is highly evaluated for its wide working range, it is also required to work in a narrow space at the same time. In order to improve the narrow-space workability while maintaining the working range, a new working machine design method utilizing electronic control is necessary. However, regarding the angle detection of the working machine, the conditions near the bucket, such as breakage and submergence, are severe, and installation is difficult. In recent years, expensive detection methods that avoid environmental conditions near buckets have been adopted in ICT construction equipment. However, adoption is difficult for mini-excavators because of the large cost burden. This paper introduces the anti-interference control of the working machine to achieve the required narrow-field workability, and the method to realize bucket angle detection, which is key for control by the potentiometer.

- Mini Excavator

- Electric Joystick

- Potentiometer

- Electronic Control

- A333

- 【Related SDGs】

-

Development of the Compact Track Loader SVL75-3 for North AmericaConstruction Machinery Engineering Dept. for Loader

Compact Track Loaders are compact construction machines used in the North American market. They have good running ability on rough terrain, high maneuverability, and versatility. Kubota launched the 75-horsepower base model SVL75 in 2010, but in recent years, there have been no significant improvements. There have been increasing criticisms that it is inferior to competitors, particularly in terms of noise and vibration, maneuverability, and its outdated operating system. Therefore, in the SVL75-3, we implemented an integrated cab and a variable control fan to reduce noise. We also focused on power source security and heat balance, and added Auto-shift control for improved maneuverability. A 7-inch LCD touch panel and a wideangle rear camera were introduced for the operating system. This article introduces these technological developments.

- Compact Track Loader

- Integrated Cab

- Auto-shift

- LCD Touch Panel

- 【Related SDGs】

-

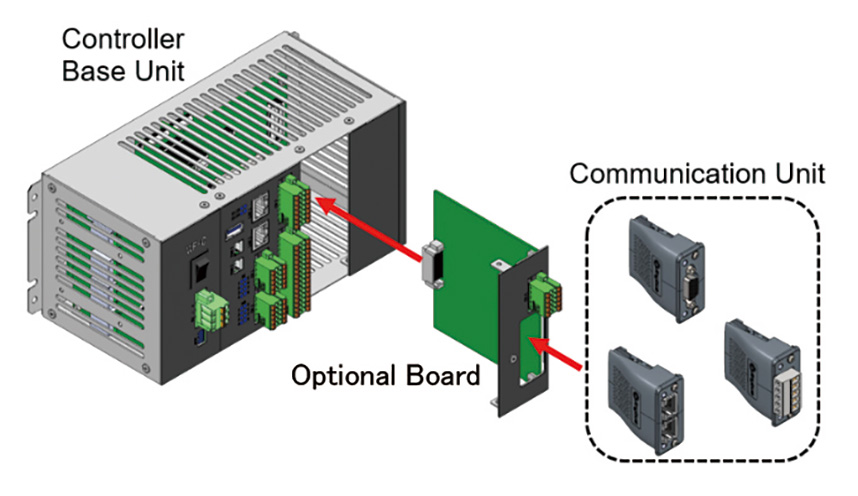

Development of a Feeder Controller with a Focus on DX at Manufacturing SitesPrecision Equipment Engineering Dept.

Kubota's feeder business has secured a high share of the global market through cooperation with Kubota Brabender Technologie, which became a subsidiary of Kubota. In recent years, the need for continuous production has increased not only in the existing resin compound market, but also in new markets, making it essential to evolve with new markets in mind. Kubota developed a feeder controller that responds to new technologies such as DX, ahead of our competitors, and also responds to changes in the manufacturing site.

- Feeder Controller

- DX

- High Connectivity

- Auto Tuning

- Remote Maintenance

- 【Related SDGs】

-

Development of an Automatic Watering Control System Based on Wilt DetectionTechnology Innovation R&D Dept. Ⅲ

In recent years, extreme weather events have become frequent, and climate change, such as rising temperatures, has become increasingly evident. As a result, the importance of greenhouse horticulture, which can control the environmental conditions, has grown significantly for ensuring a stable food supply. Additionally, due to factors like an aging population, the number of farmers is decreasing, leading to a demand for more efficient and labor-saving production methods. In response to this situation, Kubota launched its first in-house product for greenhouse horticulture, the automatic watering control system based on wilt detection (Hamirus), in October 2022. This system automates watering management for high-sugar tomatoes, contributing to labor savings in watering management and stable production. This article introduces the technology behind it.

- Greenhouse Horticulture

- Automatic Watering System

- Wilt Detection

- Image Sensing

- 【Related SDGs】

-

Water & Environment

Development of Inspection Technology for the Outer Surface of PipesPipe Systems Manufacturing Engineering Dept. / Keiyo PlantPipe Systems Quality Assuranse Dept.

Because of visual sensory inspection for ductile iron pipe, we have the risks of inspection judgement variation by the inspectors and the overlooking of defects. To solve these problems, we have developed automatic inspection technology using image analysis by AI. With this technological development, we have achieved reliability improvements in inspection and labor saving for inspectors. In addition to the production line of iron pipe, we are going to promote technology expansion to the production line of synthetic pipe.

- Ductile Iron Pipe

- AI (Artificial Intelligence)

- Image Analysis

- Automatic Inspection

- 【Related SDGs】

-

Development of a Large Diameter Electro Fusion SocketKubota ChemiX Co., Ltd

Steel pipes, which were used as piping materials in many factories built during the period of economic growth, are suffering corrosion problems due to aging. Kubota Chemix (hereinafter referred to as "KC") is promoting market development by proposing plastic pipes as an alternative to these metal pipes.

We use injection molding to continuously produce polyethylene EF fittings of φ200 or less. However, for sizes of φ250 or more, we have developed equipment and manufacturing techniques specifically for original pipe-type EF fittings, which have heating

wires embedded in short pipes, and are able to produce many models in small quantities.

- Pressure Pipeline

- Lathe Processing

- Applicability

- Electro Fusion Socket

- 【Related SDGs】

-

Development of an Automatic High-pressure Cleaning System for the Gravity Belt ThickenerWater Circulation Engineering Design Dept. / Environmental Business Planning and Sales Dept.Water and Environment R&D Dept. Ⅱ/ Environmental System Control Dept.

The “Kubota Gravity Belt Thickener” for wastewater treatment plants is low-cost, low-power, and easy to manage, and it has been widely adopted in domestic wastewater treatment plants, significantly contributing to energy savings and labor reduction. However, certain substances contained in some of the treatment targets can cause clogging on the stainless steel belt, leading to a decrease in concentration performance. To reduce the frequency of this clogging and minimize maintenance efforts, we have developed an automatic high-pressure cleaning device.

- Wastewater Sludge

- Gravity Belt Thickener

- Stainless Steel Belt

- Clogging

- High-pressure Cleaning

- 【Related SDGs】

-

Development of Inspection Rationalization Technology Using MR DevicesKUBOTA Environmental Engineering CorporationDX Planning & Promotion Dept.

Drainage pumping stations, which play a role in preventing flood damage, are becoming increasingly old after 40 years of use since their installation. Therefore, facility maintenance is becoming increasingly important. Meanwhile, the inspection workers at drainage pumping stations are aging, leading to a decrease in the number of skilled workers and issues with passing on know-how to unskilled workers. As a solution, the Ministry of Land, Infrastructure, Transport, and Tourism's Kanto Regional Development Bureau introduced "inspection rationalization technology" in April 2024 to improve the efficiency of inspection and maintenance. The Kubota Group has developed "inspection rationalization technology" using MR devices to further pursue the work efficiency required and pass on the know-how of inspection workers.

- MR Devices

- Machine Maintenance

- Server Management

- Point Cloud Data

- 【Related SDGs】

-

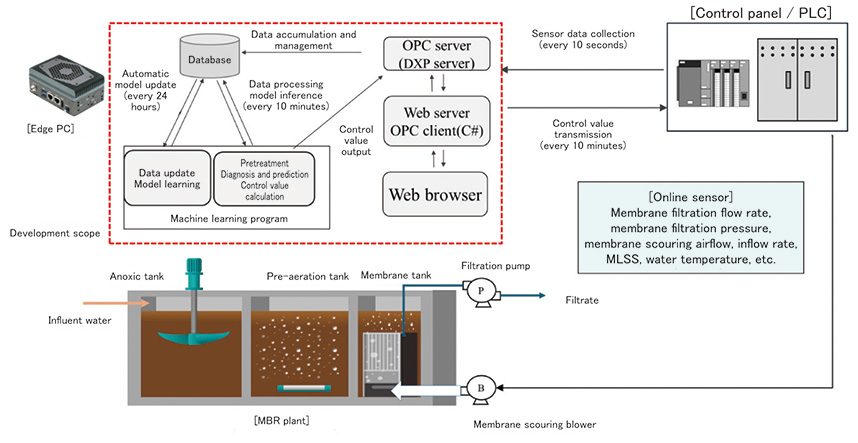

Development of the MBR Operating System with a TMP Prediction ModelWater and Environment R&D Dept. ⅡKubota Membrane USA Corporation

Membrane Bio-Reactor (MBR) is a wastewater treatment process which features superior effluent quality and a small footprint. Although it is a technology used for wastewater reuse due to its high solid-liquid separation performance, the reduction of energy and costs related to membrane scouring power is a challenge needing further discussion. In addition to hardware improvements, such as high integration of membrane modules and units, Kubota has developed a membrane scouring airflow control. This paper introduces our approach to membrane scouring airflow control using an automatically updated machine learning model that diagnoses membrane conditions. This developed system uses edge AI and can be easily introduced into existing systems, achieving more than 20% reduction in membrane scouring airflow compared to conventional models, with stable operating performance.

- MBR

- Energy Saving

- Machine Learning

- TMP Prediction

- Edge AI

- 【Related SDGs】

-

Introduction Article

Introduction of Kubota Research and Development Europe (KRDE)Kubota Research and Development Europe S.A.S.

- 【Related SDGs】

-

Introduction Article

- Diagnostic Functions of a Centrifugal Dewatering Machine to Realize Condition-based Maintenance and Stable Operation

- Polyethylene Pipe for High Pressure Fire Extinguishing Equipment