Basics

What is a valve ?

A valve is a device with moving mechanism that passes, stops or controls the flow of a fluid.

Such fluid control valves have been applied to various facilities including piping of a waterworks system, farm water supply, and sewage system.

A gate valve was the most popular type in the past, although it could not provide enough operability and control. However, as a recent increased demand for more efficient and optimized water use in larger-scale water supply/distribution facilities, various valves with different functions have been developed and adopted in fluid control applications.

See the types, characteristics, roles and applications of such valves as below.

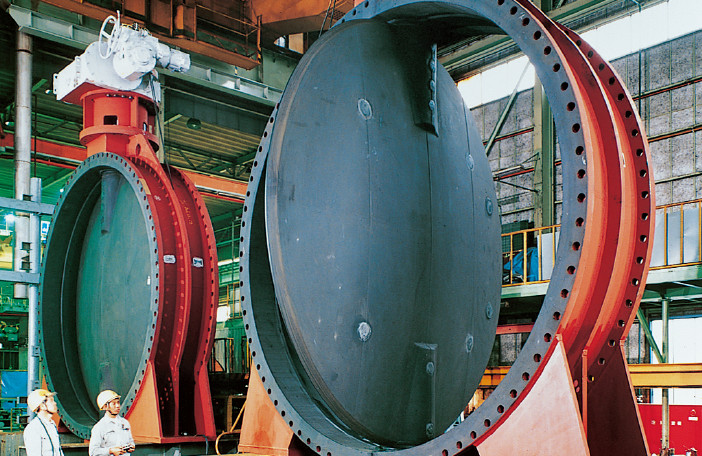

Basic structures of valves

-

Gate Valve

-

Butterfly Valve

-

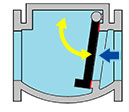

Ball Valve

-

Check Valve

Types of valves

Gate valve/Multi-hole variable orifice valve/Check valve/Fire Hydrant/Butterfly valve/Plug valve/Flap valve/Slide gate/Sleeve valve/Emergency Shut-off valve/Air valve/Ball valve

Usage and Features of valves

- Isolation Valve

-

- Gate valve

- Generally for small size pipes with DN500 and less diameter. Basically used in fully open or fully closed position.

- Resilient seated(Rising / Non-rising stem)

- Metal seated (Rising/ Non-rising stem)

- Butterfly valve

- Suitable for large size pipes in terms of operability, control, installation space, and cost.

- Rubber seated

- Metal seated

- Ported disc

- Toothed disc

- Disc-in-disc

- Wafer type

- Emergency shut-off valve

- Installed at an outlet of a distributing reservoir to prevent loss of stored water or secondary disasters in case of a piping problem.

- Electrical signal type

- Mechanical flow sensor type

- Dual service for electrical and mechanical flow sensor type

- Emergency valve for earthquake-resistant water storage tank

- Rapid closing gate

- Sluice gate

- Installed at an inlet/outlet of an open channel connected to a grit chamber or settling basin, or at an outlet of a dam.

- Ball valve

- The pressure loss is less than any other valve when fully opened. Basically used in fully open or fully closed position.

- Control valve

-

- Control butterfly valve

- The valve has a specially designed disc that enables a wider range of control than standard butterfly valves. In addition, it can reduce cavitation and is suitable for control in applications with relatively small pressure reduction.

- Sleeve valve

- The valve has two sleeves with multi-hole structure, and it is suitable for control in applications with relatively large pressure reduction. It has good performance but needs large installation space.

- Multi-hole variable orifice valve

- The valve has two plates with multi-hole structure, and it has a good control performance. It is compact and costs approximately 1/3 of a sleeve valve.

- Plug valve

- Suitable for sewage or other fluid containing slurry.

- Back-flow prevention valve

-

- Check valve

- For preventing back-flow, installed at an outlet pipe of a pump or any other pipe at an intermediate part of a pipeline.

- Swing

- Slow closing with damper

- For blowers

- Flap valve

- Installed at an outlet of a discharge pipe to prevent back-flow.

- Pipeline protection valve

-

- Air valve

- For removing air from inside a pipe during initial filling of water, supplying air during draining, and gradually removing air separated from a fluid during continuous operation.

- For potable water (High speed)

- For farm water

- For sewage

- Isolating valve

- Used as a master valve of an air valve and fire hydrant during maintenance.

- Ball type

- Butterfly type

Valve actuator

Rotation or sliding of a valve disc enabled by an actuator opens and closes a valve.

From a range of actuator types, you need to select an appropriate one according to usage, type, control method, and installation environment of a valve.

- Valve Actuation

-

- Manual actuator

- Electric actuator

- Hydraulic / Pneumatic actuator

- Others

- Float type

- Counter weight type

Supplement

Control valves and control methods

Control methods are roughly classified into flow rate control, pressure control and level control. You need to select one of them according to an intended use of a valve.

For flow rate control, a multi-hole variable orifice valve and sleeve valve are suitable due to their high control performance.

In any case, you need to consider cavitation conditions to select a valve type.

Selecting a valve based on cavitation conditions

Select a type of control valve that can satisfy the following cavitation conditions.

Obtain the operating cavitation coefficient with the following formula.

P1 : the water pressure at upstream side of the valve.

P2 : the water pressure at downstream side of the valve.

Water hammer prevention and a valve

A pressure surge by water hammer may occur when a valve opens or closes quickly. The impact differs depending on length of a pipe, flow pressure, flow rate, etc. To prevent water hammer, sudden change caused by opening/closing of a valve should be avoided as below to reduce pressure increase.

(1) Using a valve with high flow control performance

(2) Keeping an appropriate operation time for opening/closing.