Safe Workplace

Customer satisfaction cannot be accomplished without employee satisfaction. The Kubota Group promotes the creation of comfortable and motivated workplaces where its employees can not only work safely and securely but also feel pride and joy in their work.

In terms of safety, we are creating workplaces that eliminate “unacceptable risks” through risk assessment activities in Japan and overseas.

Promoting a Safer Workplace

Kubota formulated its Basic Policies on Safety and Health in April 2013 for the purpose of creating a safer and more secure workplace. Based on these policies, Kubota is enforcing the ethic whereby all people involved in the business, including contractor employees, behave based on the philosophy that “Safety is Our First Priority.”

In addition, three specific instructions to ensure the “Safety is Our First Priority” philosophy were announced by the President.

The Kubota Group’s Mid-term Plan sets out a variety of strategies aiming to achieve a goal of zero "Class A Accidents"*, centered on promoting inherently safe equipment, ensuring safe operations, and enhancing human resources development to support safety.

- Class-A accident is one that can lead to a serious accident, such as crushing or entanglement in machinery, due to one of the following causes:

1) Contact, etc. with high-heat object, 2) Contact, etc. with heavy load, 3) Entrapment and entanglement by machines, 4) Fall from heights, 5) Contact, etc. and the like with forklift / vehicle, 6) Toppling of or contact with agricultural machines, construction machines or other vehicles (products), 7) Electric shock, 8) Contact with flying / falling object, 9) Contact with hazardous materials, Acute poisoning (including lack of oxygen, etc.), or 10) Occupational accident caused by explosion or fire.

- The Kubota Group Basic Policies on Safety and Health

-

“In the Kubota Group, no work should be carried out

without serious consideration of safety and health.”To achieve this, we established the fundamental principle that all the people involved in the business shall behave based on the philosophy that “Safety is Our First Priority.”

- Safety is Our First Priority

-

- All the people involved in the business of the Kubota Group shall observe the determined rules and behave based on the philosophy “Safety is Our First Priority,” to protect themselves from accidents.

- Management executives shall operate the business keeping in mind the philosophy “Safety is Our First Priority,” respect and listen to the voices of frontline worksites, and be reminded that “the worksite is a mirror that reflects yourself.”

- Management-level employees shall identify any risk that may lead to a serious incident and take faithful action to address such risk, while endeavoring to create a corporate culture that allows straightforward talk about safety and to develop human resources that support safety.

Mid-Term Plan Targets and Major Initiatives

Under our mid-term plan, which ends in FY2027, we are implementing the following key initiatives.

Target: Zero "Class A Accidents"

[Major initiatives]

- Raising the level of risk assessment activities

- Consistently implementing machinery risk assessments when new equipment is installed or when equipment is modified.

- Identifying risks, with “hazard identification*” and “human behavior, including reasonably foreseeable misuse*” embedded in the process.

- Checking sites for hazards using illustrated lists of similar issues.

- Expected unsafe behavior, including spur-of-the-moment actions and shortcut behaviors.

- Risk reduction activities that prioritize equipment measures

- Reducing risk by installing equipment with inherently safe designs and fitting guards and protective devices, in line with the three-step safety model*.

- Compiling specific examples of risk reduction in the Safety Control Guidelines* for assessment and promotion of inherently safe equipment

- A risk reduction method with three steps: (1) Use equipment with inherently safe designs, (2) employ safeguardings and complementary protective measures, and (3) provide information for use.

- Guidelines that categorize various types of equipment according to their level of safety.

- Risk reduction activities through safe work practices

- Standardizing safe work practices to address risks that cannot be reduced through equipment measures. Supervisors check work on a daily basis to ensure operations are performed in line with the standards.

- Preventing the recurrence of any abnormalities by rigorously enforcing the “Stop, Call and Wait.” safety approach.

- Enhancing personnel development to support safety

- Maintaining a staffing structure that can support safety controls and management systems.

- Systematically cultivating human resources for (1) above.

- Maintaining and improving a safe and healthy working environment

- Developing and implementing noise-reduction plans for manufacturing sites

- Responding to revisions to chemical substance laws

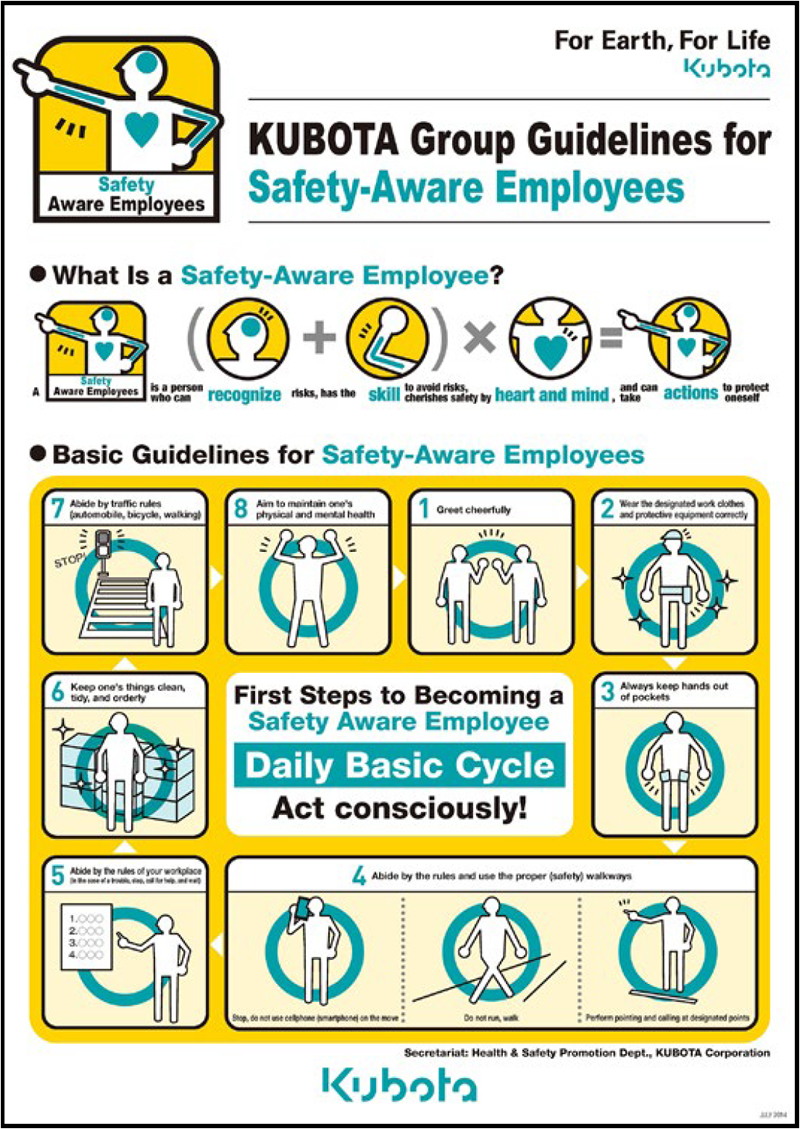

Kubota Group Guidelines for Safety-Aware Employees/

Basic Guidelines for Safety-Aware Employees

Status of Initiatives in FY2023

In FY2023, the entire Kubota Group, including overseas companies, implemented the following initiatives.

-

Risk identification activities

We designated one day during Japan’s National Safety Week as“Kubota Group’s Safety Day.” On this day, production plans are adjusted to allow all employees to take part in safety activities.

“Hazard identification” was one of the common themes implemented Groupwide for "2023 Kubota Group's Safety Day."

Activities were used to fine-tune risk identification and other areas. -

Implementing measures based on the Safety Control Guidelines for assessment and promotion of inherently safe equipment

For existing equipment, we prioritized equipment measures to reduce identified risks. For new equipment, we conducted machinery risk assessments to introduce equipment with minimal residual risk. -

Standardization of safe work practices

For operations with risk that cannot be reduced to acceptable levels through equipment measures, we standardized safe work practices, conducted education and training, and supervisors performed daily checks and provided instructions. -

Initiatives to help build a “Stop, Call and Wait" culture

All work sites implemented the “Stop. Call. Wait.” safety approach in the event of troubles. They also worked to prevent the recurrence of troubles and trained human resources to handle them. -

Maintaining and improving working environments

We are complying with chemical substance regulations that are scheduled to be progressively revised in Japan.

The Kubota Group Safety and Health Target for FY2024

Kubota has clearly set the target below for FY2024, and is promoting Company-wide efforts to create safe workplaces.

Target: Zero "Class A Accidents"

[Priority implementation issues]

Plant and R&D departments

- Risk identification

- Promotion of inherently safe equipment

- Promotion of safe work operations

- Developing of safety-aware employees

- Promotion of sanitary management

- Maintenance of the safety management system

Construction departments

- Developing Safety-Aware Employees

- Promoting safe operations

- Promoting inherently safe equipment

- Promoting sanitary management

- Promoting environmental management

Safety Training and Awareness

We provide safety education through messages issued by management and our workplace management and through a range of conferences.

- Distribution of awareness-raising messages

Messages from management (executive officers) and workplace management (foremen/project directors) around the themes of the Kubota Group Approach to Safety and Safety-Aware Employees were distributed via the company intranet to promote safety awareness throughout the organization. -

Safety and Health Convention

The convention featured video presentations of case studies, including interviews with key personnel involved in safety activities at each site conducted beforehand, as well as a discussion between safety managers at overseas sites, the President and the General Manager of the Health & Safety Promotion Headquarters, which was held on the stage in the main hall at Head Office. There was also a lecture by an outside instructor to further raise the level of health and safety activities. (Streamed live to all sites; archived for viewing later) - Safety education initiatives

Health and safety education, particularly for new employees but also for personnel of all ranks, was conducted online or in group format, depending on training content. We devised new learning methods, such as group work using tools that enable joint editing in real time.

-

Health and safety convention

-

Discussion between the safety manager of an overseas site (China), the President and General Manager of the Health & Safety Promotion Headquarters

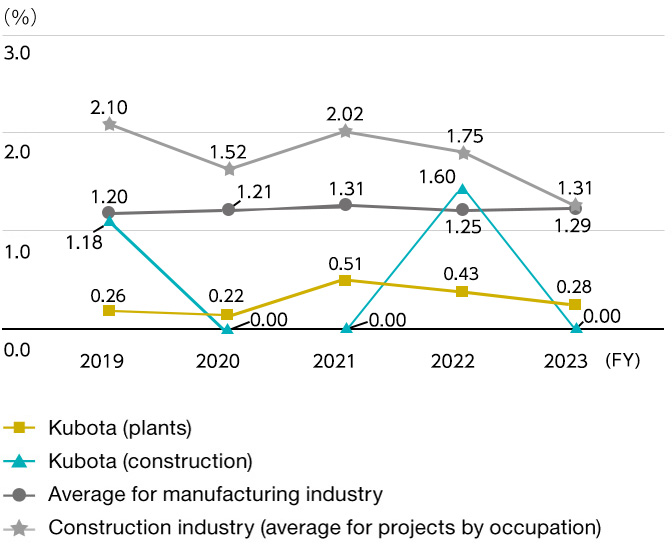

Lost Time Incident Rate/Severity Injury Rate

-

Lost Time Incident Rate (Kubota Corporation)

<Lost time incident rate>

Work-related deaths and injuries requring work absence ÷ toal personnel hours × 1,000,000 -

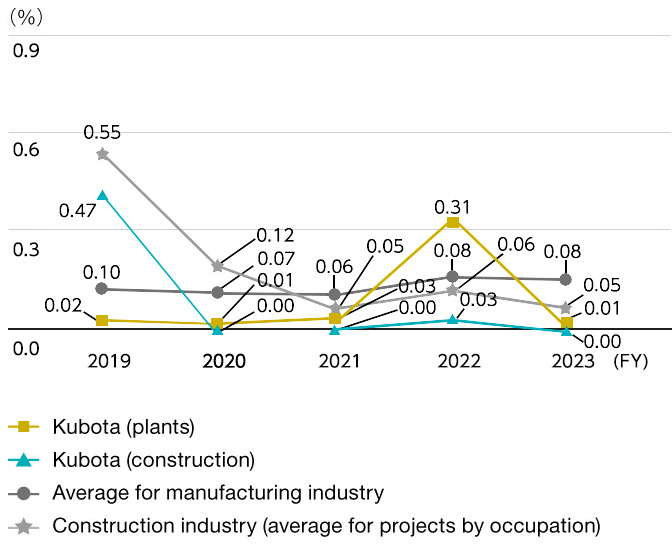

Severity Injury Rate (Kubota Corporation)

<Injury Severity Rate>

Number of workdays lost ÷ total personnel hours × 1,000

Implementation Outcomes of Safety Training Programs

Safety and health education is provided for each rank, including for new employees (education at the time of employment).

| Name of education program | No. of times held | Total participants |

|---|---|---|

| Education for new employees | 10 | 529 |

| Elementary (for young employees) | 12 | 352 |

| Semi-intermediate | 5 | 146 |

| Training for group leaders | 4 | 77 |

| Intermediate (for mid-level employees) | 2 | 61 |

| Training for newly appointed supervisors | 4 | 98 |

| Training for newly appointed foremen | 1 | 6 |

| Name of education program | No. of times held | Total participants |

|---|---|---|

| Education for new employees | 3 | 317 |

| Safety and health education for midcareer entrants at the time of employment | 12 | 363 |

| Equipment safety education | 8 | 121 |

| Training for newly promoted managers | 86 | 205 |

| Training for newly appointed section managers | 7 | 122 |

| Training for newly appointed department managers | 2 | 64 |

| Education for officers (Safety, Environment, and Quality Forum) | 1 | 28 |

- Figures for the total number of participants are rounded to the nearest five, except in the case of “education for officers.”

Sites with Occupational Health and Safety Management System Certification (OHSAS 18001)

To ensure safety for employees and provide them with a workplace environment that allows them to feel safe concentrating on their duties, Kubota has acquired OHSAS 18001/ISO 45001 certifications for its business sites below, while establishing an occupational health and safety management system focusing mainly on risk assessment for other sites.

| Tsukuba Plant | ISO 45001 certification acquired in Nov. 2020 (OHSAS 18001 certification acquired in Dec. 2000) |

|---|---|

| Keiyo Plant | ISO 45001 certification acquired in Nov. 2018 (OHSAS 18001 certification acquired in Dec. 2002) |

| Ichikawa Plant | ISO 45001 certification acquired in Nov. 2018 (OHSAS 18001 certification acquired in Dec. 2002) |

| Hanshin Plant (Mukogawa) |

ISO 45001 certification acquired in Oct. 2020 (OHSAS 18001 certification acquired in Nov. 2003) |

| Hanshin Plant (Amagasaki) |

ISO 45001 certification acquired in Oct. 2020 (OHSAS 18001 certification acquired in Apr. 2005) |

| Hirakata Plant | ISO 45001 certification acquired in Apr. 2019 (OHSAS 18001 certification acquired in Jun. 2007) |

| Kubota Construction Co., Ltd. | ISO 45001 certification acquired in Dec. 2020 |

|---|---|

| KUBOTA KASUI Corporation | ISO 45001 certification acquired in Dec. 2020 |

| Kubota Materials Canada Corporation | ISO 45001 certification acquired in Feb. 2021 (OHSAS 18001 certification acquired in Aug. 2012) |

|---|---|

| SIAM KUBOTA Corporation Co., Ltd. | ISO 45001 certification acquired in Sep. 2019 (OHSAS 18001 certification acquired in Jan.-Feb. 2014) |

| Kubota Baumaschinen GmbH | ISO 45001 certification acquired in Jun. 2019 (OHSAS 18001 certification acquired in Jul. 2014) |

| SIAM KUBOTA Metal Technology Co., Ltd. | ISO 45001 certification acquired in Nov. 2019 (OHSAS 18001 certification acquired in Dec. 2014) |

| KUBOTA Engine (Thailand) Co., Ltd. | ISO 45001 certification acquired in Jul. 2019 (OHSAS 18001 certification acquired in Jul. 2015) |

| Kubota Farm Machinery Europe S.A.S | ISO 45001 certification acquired in Oct. 2021 (OHSAS 18001 certification acquired in Feb. 2017) |

| KUBOTA SANLIAN PUMP (ANHUI) CO., LTD. | ISO 45001 certification acquired in Jun. 2019 |

| Kubota Construction Machinery (Wuxi) Co., Ltd. | ISO 45001 certification acquired in Nov. 2019 |

| Kubota Engine (WUXI) Co., Ltd. | ISO 45001 certification acquired in Nov. 2019 |

| Kubota Saudi Arabia Company, LLC | ISO 45001 certification acquired in Jan. 2020 |

| Kubota (U.K.) Ltd. | ISO 45001 certification acquired in Oct. 2022 |

| Kverneland AS Ravenna | ISO 45001 certification acquired in Aug. 2023 |

Reducing Risk for Employees Working Overseas

With the collaboration of specialist international medical treatment and security companies, the Kubota Group is working to reduce risk for employees posted overseas and their accompanying family members and for employees on business trips overseas.

By collecting and analyzing security information at the overseas location, we provide information to Group employees in Japan and overseas. To deal with medical needs, we have rolled out a system that provides services including consultation with a doctor by telephone from overseas and arrangement of emergency medical transport.