Expanding Environment-conscious Products and Services

The Kubota Group is contributing to protecting the global environment and solving social issues in the food, water and living environment fields through the provision of environment-conscious products and services. The Group conducts environmental assessment of products in the design and development stages, and promotes environment- friendliness over the entire product lifecycle, from the procurement of raw materials to the disposal of products. The Group internally certifies exceptionally environment-conscious products as Eco-Products, and is working to expand its lineup of certified products.

- 【ESG Report】Expanding Environment-conscious Products and Services

- Medium- and Long-Term Environmental Conservation Targets and Results

Activities towards achieving SDGs

| Related SDGs and target |

|

|---|---|

| Major Activity Content |

|

| 2030/2025 Activity Targets (KPIs) |

|

Environmental Considerations in the Product Life Cycle

1. Major Initiatives to Ensure Environment-friendliness

2. Analysis of Greenhouse Gas Emissions in the Product Lifecycle

The Kubota Group handles a diverse range of products, from agricultural and construction machinery to pipe systems and water treatment equipment. As part of its product environmental assessment, the Group conducts lifecycle assessment (LCA) for its major products to determine the amount of greenhouse gas emissions over each product lifecycle. The results of the LCA were subject to third-party review in 2014 by the Japan Environmental Management Association for Industry.

-

Results of LCA: Proportions of Greenhouse Gases

- *1.LCA results for tractors were calculated based on the assumption of towing and transporting work for 5,000 hours by the M9540DTHQ-EC agricultural tractor in France.

- *2.LCA results for ductile iron pipes were calculated based on the data reported in the “Study on Piping Technologies for Sustainable Water Supply Service” (Japan Water Research Center). The proportions of raw material procurement, manufacturing, and product transportation were determined according to Kubota's CO2 emissions data.

Greenhouse gases emitted in the use stage account for around 90% in the lifecycle of agricultural tractors, while gases emitted in the manufacturing and construction stage account for around 90% in ductile iron pipes. Thus, the frequency and scale of environmental loads in the lifecycle vary depending on the product type. The Kubota Group enhances its environment-conscious products and services by reflecting the results of the analysis of environmental loads in the product lifecycle in its environment-conscious design development.

Internal Certification System for Eco-Products

1. Regarding the Internal Certification System for Eco-Products

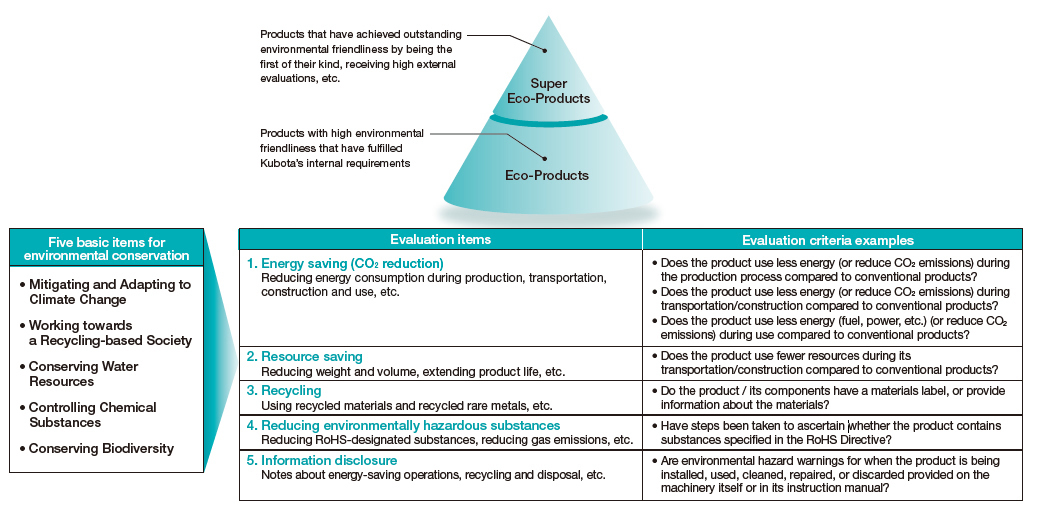

The Kubota Group's internal certification system for Eco-Products was introduced to internally certify products with exceptional environmental friendliness. We evaluate products in accordance with matters related to the five basic items for environmental conservation in the Kubota Group's environmental management, namely, “Tackling Climate Change,” “Working towards a Recycling-based Society,” “Conserving Water Resources,” “Controlling Chemical Substances,” and “Conserving Biodiversity,” and certify those products that satisfy our internal standards as Eco-Products.

2. Eco-Products Certification Committee

The Eco-Products Certification Committee, chaired by the General Manager of the Manufacturing Headquarters, consists of the committee members elected from each Division, as well as the Research and Development Management Department and the Environmental Protection Department. Upon receiving an application from each Division for the certification of a product, the Committee examines the product's adequacy as an Eco-Product and gives certification.