Vertical Mixed Flow PumpDF-VS

Download CatalogHigh Performance

Bowl configuration has been simplified by using Duplex Stainless Steel plate while obtaining high efficiency. Improved suction performance has been achieved by using advanced analysis technology.

Light Weight and Compact

Duplex Stainless Steel plate is used for pump main parts. 30% lighter compared to the previous stainless steel casting type.

High-reliability

Improved corrosion resistant by using Duplex Stainless Steel. Fabrication based on reliable welding techniques of Duplex Stainless Steel through various element tests.

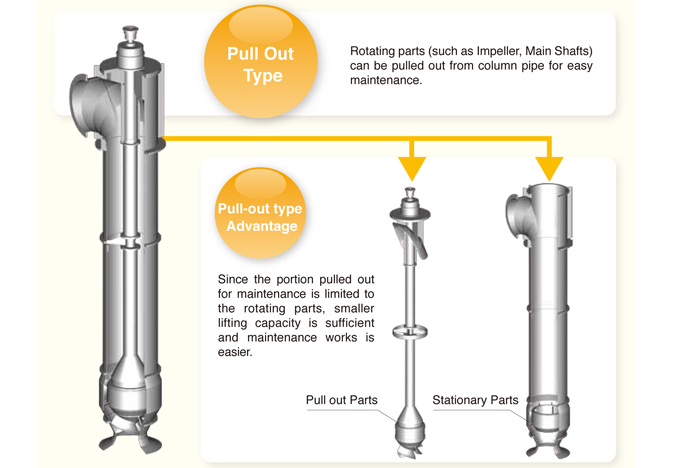

Easy in Maintenance Impeller

Easy maintenance work by pump light weight. Shorter delivery time compared to pumps made of stainless steel casting.

- Suction bore

- 1,200~2,200mm

- Capacity

- 180m3/min~800m3/min

- Total head

- 10m~100m

Application

MATERIAL

| Wet parts | Duplex Stainless Steel |

|---|---|

| Dry parts | Carbon Steel |

*Duplex Stainless Steels has a two-phase microstructure consisting of grains of ferritic and austenitic satinless steel which leads to it’s excellent anti-corrosion and high strength properties.

Super Duplex Stainless Steel can be applied as option.

PUMP SPECIFICATION

| Discharge Flange | ISO7005-1 PN-10 Option) ASTM, ANSI and other standard |

|---|---|

| Installation | 1 Floor / 2 Floor |

| Fluid | Seawater / Brackish |

| Temperature | 0℃ ~ 50℃ |

| Sealing | Gland Packing / Mechanical seal |

| Thrust bearing | Anti-friction, oil bath lubrication Option) Tilting-pad type |

| Radial bearing | Rubber or Teflon, water lubrication |

OPTION